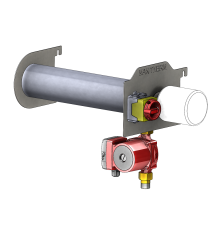

Circulation pump for a flow-through water heater

The circulation pump for the heating system is a mandatory component for the operation of a flow-through heating system used for heating the water serving as a heat transfer medium inside the duplicator of industrial cooking boilers, mixers, reactors, and vacuum evaporators in food production. It is selected based on the required parameters of the heating system (volume). Our specialists will be happy to assist you in selecting the appropriate pump if you provide the technical specification requirements. This pump is an essential additional component for the flow-through water heater┬Āup to 110┬░C.

- It can be used to circulate water at temperatures up to 110┬░ C

- High efficiency with low power consumption

- Also suitable for central heating systems, heated floors and even for solar systems

- Small connections allow the use of flexible pipes with a smaller diameter

The circulation pump for high-temperature flow-through heating systems is a necessary element for efficient heating and heat transfer in heating jackets (duplicators) of industrial food processing equipment for cooking, boiling, concentrating and evaporating products in cooking boilers and reactors.

Electric flow-through heating systems can be used for a large variety of cooking boilers, where the circulation pump performs the function of feeding the thermal transfer medium into the heating jacket.

Advantages

- The components and materials are highly resistant to aggressive water with a high mineral content, which allows the pump to be used for a longer period of time without maintenance

- A special design feature is the ability to disconnect the control unit during maintenance, no complete dismantling of the pump is required

- Several pump speeds allow for better regulation of the flow volume

- It has compact dimensions and a wide range of performance options

- Quiet pump operation at high speeds due to the special bearing material

Technical parameters

- Flow rate: 18-48 l/min; 28-55 l/min

- Power supply: 220-230 V/50 Hz

- Rated current: 0.41 A

- Average temperature: 2ŌĆō110 ┬░C

- Protection: IP44

- Maximum pressure in the pipeline: 10 bar.

- Power: depends on the speed (1/2/3): 46 W/63 W/93 W

- Type of the equipment: Optional equipment

You might also like

A flow-through water heater is a device for flow-through electric heating of water in heating systems for cooking boilers, evaporators and other units where it is necessary to supply a hot heat transfer medium - superheated water - to the heating jacket (duplicator). When choosing a flow-through heater, it is necessary to select a circulation pump based on the volume of the jacket or heat transfer vessel.

- The heater allows you to heat water up to 110 degrees

- Easily integrated into heating systems

- Has heating temperature regulation

- 2 stages of heating power adjustment

- Independent control panel with protection against overheating and "dry" running

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2/ 3/ 6/ 9/ 10/ 12

- Principle of operation: Continuous mode

The expansion tank is an additional component of the heating system circuit, where flow-through electric heating is used as an independent closed system for heating the hot water, serving as a heat transfer medium circulating in the duplicator of food cooking boilers, reactors, pasteurizers, and other food processing equipment. In heating systems with water heaters operating at temperatures up to 110┬░C, the expansion tank is necessary to accommodate the increased volume of the heat transfer medium as it expands when heated.

- Special high-pressure vessel ŌĆō allows to withstand pressure of up to 5 bar in the system.

- Allows the use of a heat generator with superheated water up to 110┬░C.

- Has different volume options, depending on the volume of the heat transfer medium, selected additionally.

- Type of the equipment: Optional equipment

The pump provides a delicate straight-streaming┬Āpumping of a wide range of liquids with or without solid fragments with viscosity up to 150 Pa.s.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

Vane pumps are used for pumping high viscosity products such as syrups, honey, mayonnaise, sauces, cream and many other products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of pump: rotary vane

Stainless steel low-speed rotary pumps with a flexible impeller; We offer two versions. On base or trolley.

- Principle of operation: Continuous mode

Centrifugal impeller pumps are ideal for various industrial applications such as food processing, manufacturing, washing and surface treatment of metal pieces, boxes, containers, glass jars and vessels. These pumps are also suitable for dishwashers, bottle washing lines, painting processes, and pumping liquids into various chambers.

- Principle of operation: Continuous mode

This pump is a monoblock single-stage liquid ring vacuum pump suitable for low, medium, and high vacuum applications. It is an economical pump with exceptional performance and reliability.

- Productivity: 52 m3/h

- Principle of operation: Continuous mode

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

- Principle of operation: Continuous mode

The single-stage vacuum pumps are versatile, offering a wide range of applications when it comes to transporting liquids due to their simplicity, reliability, and robustness. The device operates with minimal vibrations, and its noise levels do not exceed the prescribed standards. Additionally, it ensures oil-free operation.

Electric continuous flow heaters in different designs and performance parameters.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Type of pump: sealless pump

The high-performance screw pump is used for pumping both thick and viscous food products, as well as various masses containing pieces or solid inclusions such as in the cosmetics, cosmetology, and other industries.

- High performance

- All parts in contact with the product are made out of AISI304

- Does not damage products containing solid pieces

- Additional options: by-pass

- Material: Stainless steel

- Engine power, kW: 1,1/ 1,5 / 3

- Principle of operation: Continuous mode

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

The fruit mash pump is designed for efficiently transporting mashed fruits from a crusher to a press for extracting juice.

- Productivity: 6000 kg/h

- Material: Stainless steel

- Engine power, kW: 1,85

- Voltage: 380-400V

One of advantages of this glandless pump is very high durability and efficiency in operation in very demanding conditions. We offer glandless pump with different power variations.

- Principle of operation: Continuous mode

The homogenizer is designed to homogenize, mix and disintegrate / grind different fluids and components into small particles.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

We offer different types of pumps for different applications.

- Principle of operation: Continuous mode

Centrifugal pump designed for pumping low viscosity food and aggressive liquids.

- Principle of operation: Continuous mode

Monoblock pumps with an integrated frequency converter. We offer many different types of pumps, if you need any advice on which pump to choose, feel free to send us the request.┬Ā

- Principle of operation: Continuous mode