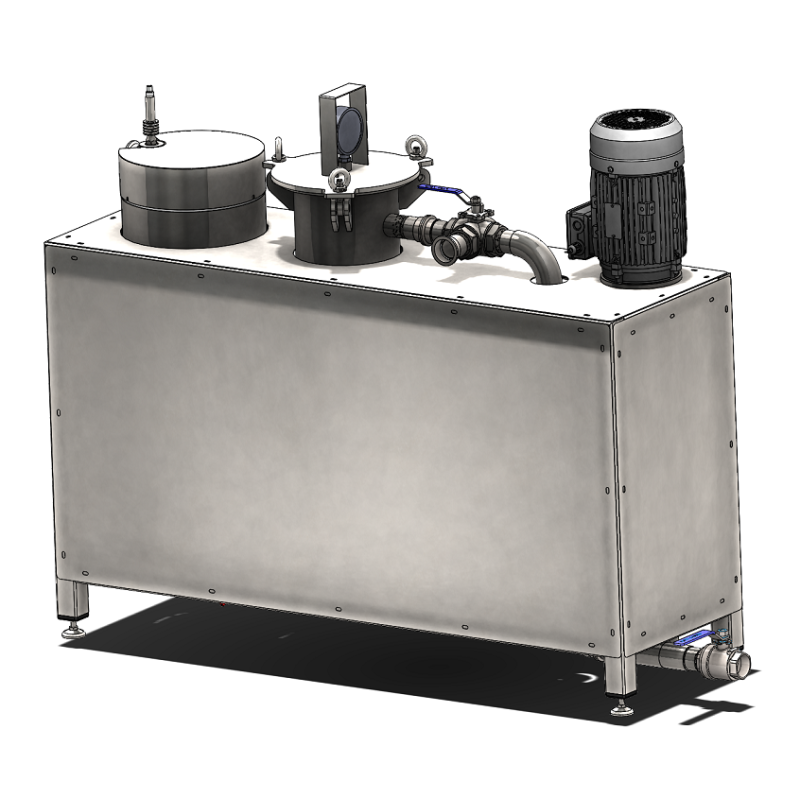

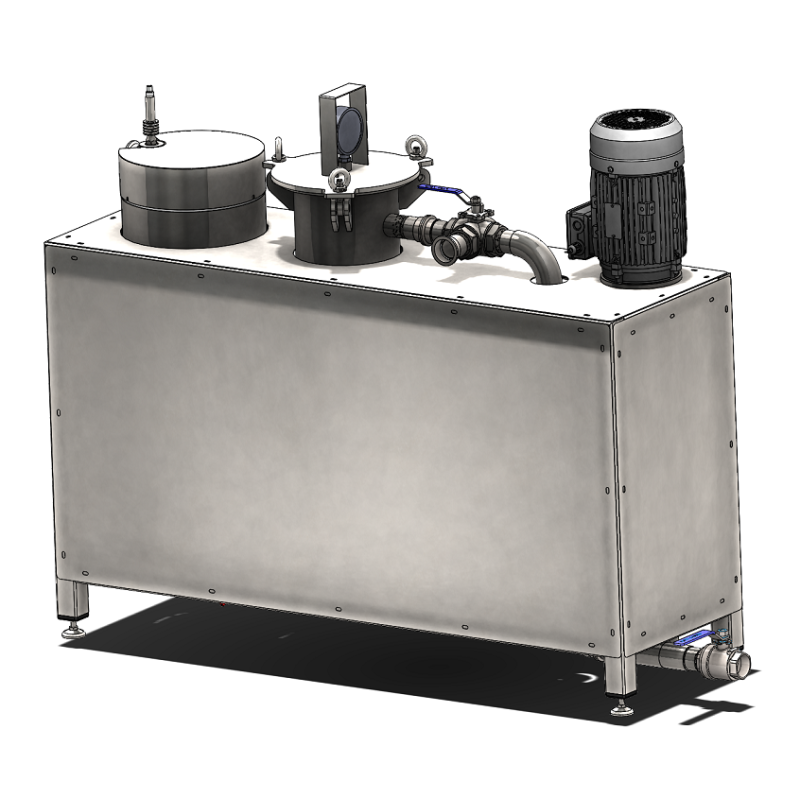

Oil heating, filtering and pumping station UniTherm

Electric continuous flow heaters in different designs and performance parameters.

All products features are manufactured with highest quality and flexibility to adapt the heater perfectly to any application.

Stainless steel construction ensures a long useful life. The compact system consists of a hot oil pump for circulating heat transfer edible oil under high temperature conditions, a filter station and heating elements. Most models can be adapted to be used with edible oil where the temperature is 180 degrees. The filters are made of heavy stainless steel components to meet the most demanding applications. The filter is basket - the mesh is selectable according to customer requirements

Features

- High strength

- Special sealless pump for maximum efficiency in hot applications.

- Easy maintenance - easy replacement of the heating element

- Filtering of oil

- Thermal insulation of corpus

Options

- controlled heating by PLC or controller

- control of each heating element separately

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Type of pump: sealless pump

You might also like

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Working Area Width: 420 mm

We offer different types of continuous fryers, let us know which product you wish to fry and we will help you choose the right fryer for your business.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

We have various types of continuous or batch fryers. Just tell us what kind of product you wish to fry and we will help you choose the right deep fryer.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The automatic screw cooker is designed for cooking or blanching various food products in continuous mode, saving both time and energy during production.

- Heating: Mixed

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A pouring fryer is a specialized equipment used in commercial kitchens for frying foods using a continuous pouring method which helps to close down the pores of the product to prevent excessive oil absorption. It offers precise control over the frying process by continuously pouring oil over the food, ensuring even cooking and consistent results.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Our continuous fryer is designed for frying cutlets, potatoes, meatballs, croquettes, fish, vegetables and many other products. Working volume up to l: 300 l.

- Material: Stainless steel

- Heating power, kW: 40

- Principle of operation: Continuous mode

- Oil volume: 300 l

- Voltage: 380-400V

The continuous pouring fryer is designed to fry meat, fish, vegetables and pasta products as well as chicken drumsticks, cutlets, nuggets, croutons, sliced zucchini or eggplant, and etc. using immersion frying and hot oil pouring methods.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The cyclone filter effectively separates particles and contaminants from air or gas streams, ensuring product quality and maintaining equipment efficiency, particularly important in the food industry.

- Material: Stainless steel

- Volume: 150l

Strainer filter protect product or production machines from mechanical damage, keep undesirable particles away from your product to help to prevent production downtimes.

- Material: Stainless steel

- Country of origin: EU

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A hot oil filter for continuous industrial tabletop fryers allows you to quickly and effectively filter oil immediately after the frying process.

- Hot oil filtration - oil temperature up to 200 ┬░C.

- Optional filter material - paper, stainless steel

- Material: Stainless steel

- Country of origin: Slovakia

Flow type magnetic separator for liquid mixtures with a manual cleaning.

- Material: Stainless steel

- Country of origin: Slovakia

Flow frying oil filter CFC offers a combined solids recovery option, as well as additional filtration support.

- Material: Stainless steel

- Principle of operation: Continuous mode

The sorption filter 3000l refers to non-pressure equipment of periodic action for filtering liquids using bulk filtering agents and different sorbents.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 3000

A filter designed for continuous fine filtration of conveyor fryers using vegetable oil, and other frying fats.

- Material: Stainless steel

- Operation mode: Automatic

- Type of the equipment: Optional equipment

- Working Area Width: 400 mm

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

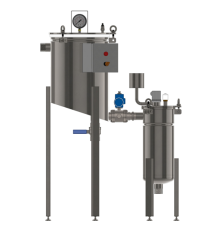

Electric continuous flow heaters in different designs and performance parameters.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Type of pump: sealless pump

Compact and easy to use filtration system for oil is used for the purification of oil which allows to extend it's use.

- Material: Stainless steel

- Type of the equipment: Individual machine

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

Honey filter - an effective solution for filtering honey from various inclusions and impurities at an industrial scale.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Hops filters for dry hopping using pellets for seasoning and additional bitter flavour to the beer.

- Material: Stainless steel

- Volume: 60l/

A honey processing machine with preheating and filtering, suitable for industrial honey processing facilities.

- Material: Stainless steel

- Voltage: 220-230V

Compact food filtration equipment with 12 filtering units. Unique filtration purifies products to very high standard- all materials used are perfectly compatible with liquids for human consumption.

- Engine power, kW: 0,34

- Principle of operation: Continuous mode

- Weight: 16