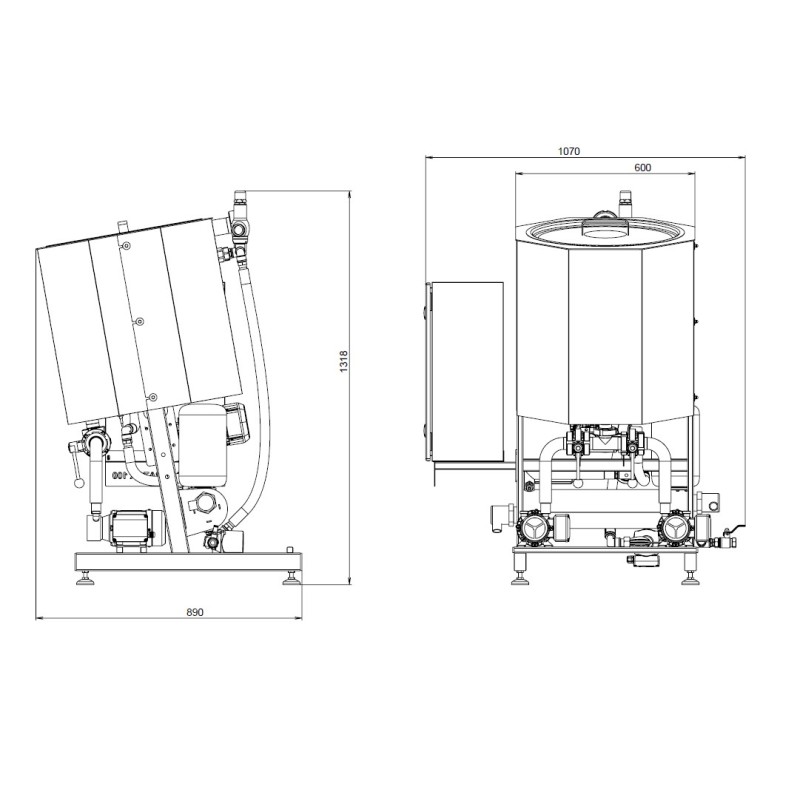

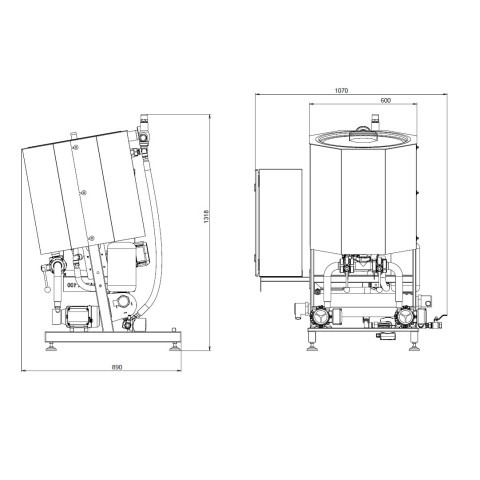

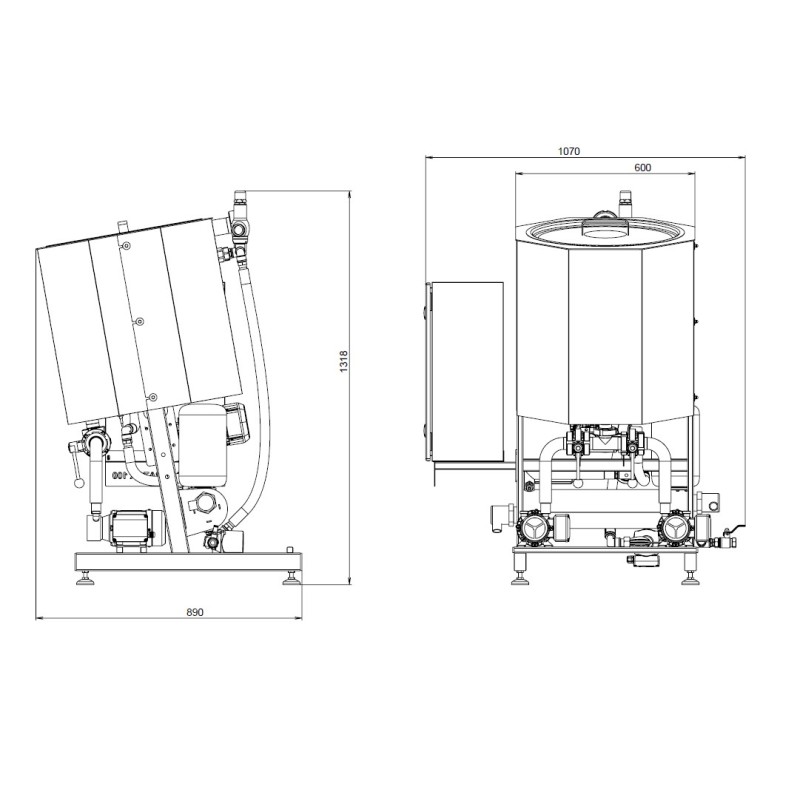

Tank with a mixer and jacket for the thermal carrier 100-900 L

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitŌĆÖs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

Atmospheric mixers with a frame stirrer and a jacket for the heat transfer medium (for heating or cooling) are suitable for use in the food, cosmetic, chemical, and many other industries, as they allow a wide range of processes to be performed, including:

|

|

|

|

|

|

|

|

|

Atmospheric tanks with a stirrer and a heating/cooling jacket are suitable for the production of such products as:

|

|

|

|

|

|

|

|

|

|

|

|

And much more!

Advantages:

- Hygienic design: virtually eliminates product contamination after washing, as there are no blind zones inside the reactor.

- No dead corners due to gravity mixing, the product flows to the lowest point, from where it is raised by the mixer and mixed into the total mass. Gravity mixing is 50% more efficient than usual. It allows intensive mixing, and the mixing of thick and viscous products.

- The inclined design of the unit also helps to quickly unload the product while the mixing device is on.

- The unit can be equipped with various types of frame mixing devices.

- The heating/cooling jacket up to 0.5 bar allows the use of steam or hot water as a heat carrier for heating, and if cooling is necessary, cold water or glycol can be supplied to the jacket.

- A professional stainless steel temperature sensor is installed in the bottom of the working tank, certified for use in contact with food products.

- Robust design, all components are supplied only from European manufacturers. All connections, joints, fittings are made only out of stainless steel AISI 304 and 316L, connections - fittings used in dairy processing from German manufacturers such as AWH. All connections have high-temperature Viton seals. The tanks are resistant to acids, alkalis and high temperatures.

- The internal surfaces are polished to RA Ōēż 1.6 ┬Ąm. Mirror internal surfaces (for the pharmaceutical industry) can be ordered as an option.

- Convenient maintenance due to the inclined design even with large installation volumes. Space saving in production facilities ŌĆō compact, high-performance tanks.

Basic version:

The basic version of the unit is equipped with a frame stirrer with a professional industrial three-phase gear motor. The reactor has a two-layer casing with a heating/cooling jacket (up to 0.5 Bar). Optionally, thermal insulation with an external decorative casing can be installed. In the basic version, the internal surfaces of the mixer are polished, the welds are cleaned and etched. Optionally, the internal surfaces of the mixer can be polished to Ra <0.4 ┬Ąm. Hot water or steam can be used as a heat carrier.

Options:

- A professional stainless steel temperature sensor in the product at the bottom of the tank with a control panel in the form of a temperature controller

- Various types of mixing devices

- Scrapers for the agitator

- CIP heads

- Hot water supply source

- Steam generator

- Ice water stations

- Thermal insulation with an external decorative casing

- And much more...

The images contain models with the maximum configuration, and are posted for informational purposes. Actual installations may differ from those shown.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

A large stainless steel pot with a drain valve and a temperature sensor can be used on any cooking surface: electric, gas, induction.

- Large 6/4'' drain valve

- Multi-layer sandwich bottom

- Cooking pot wall thickness 1 mm

- Professional, high-temperature temperature sensor

- Material: Stainless steel

- Volume: 50l/ 100l/ 150l

- Diameter, mm: 400/ 500/ 600

The brewery boiler comprises a two-pot-shaped assembly, in which the integrated frame is a built-in lauter tun, a mash tank, a whirlpool, a laboratory sink and a control panel.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1800l

The price is indicated for the basic version of the vacuum reactor without additional options, the final cost depends on the modifications

The vacuum homogenizer is an ideal solution for the production of food, for example mayonnaise, it is also suitable for the cosmetics industry - the production of toothpaste. This model of the homogenizer is based on a vacuum reactor with an external homogenizer and an external circulation circuit, the parameters of which are selected as options.

- Tilted design - 25% more efficient mixing

- Easily disassembled reinforced frame mixer, for thick and viscous products

- Jacket for the coolant around the bottom and walls of the working reactor

- The vacuum reactor can withstand a vacuum up to -0.8 Bar

- A large number of options to choose from to suit various requirements

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 650l

- Total power, kW: 0,55

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel

A vacuum deaerator is extensively used in the food industry to remove gases from products that may retain some bubbles post-processing. Additionally, a flow deaerator is utilized to minimize foaming in products, ensuring a denser structure, especially prior to packaging. Vacuum deaerators play a crucial role in eliminating specific odors from the products, such as in the production of juices, purees, and herbal drinks. This process significantly contributes to enhancing the overall quality and taste of the final product.

- Enhances product quality, structure, and shape

- Prevents oxidation by removing gases

- Preserves organoleptic properties and extends the shelf life

- Suitable for thick and viscous products

- The flow principle allows for the installation of this equipment in existing production lines

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

The professional cooking vat is designed for dairy products processing. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Heating power, kW: 24

- Volume: 150l/ 300l/ 500l

Vacuum evaporator with remote circulation using a heat exchanger is one of the most efficient evaporation methods. This evaporation system is suitable for boiling and concentrating heat-sensitive products such as milk, cream, etc.

- No mixing device required, the product has forced circulation!

- Modular system: possibility to choose the vacuum generator, power and heat exchanger type

- Inclined design and bottom valve for 100% product discharge without losses and blind spots

- Insulated upper hatch of the unit for heat retention and safety

- Tangential product inlet into the vacuum vessel for guaranteed evaporation in a thin layer

- Material: Stainless steel

- Volume: 50l/ 100l/ 300l

The cooling tank is designed for storing milk and other beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

Tilting bratt pans with mixer are frying the product with continuous stirring. Designed for catering industry, school kitchens, restaurants and food industry. Variants of heating systems: direct electric and direct gas. Capacity: 150, 200 or 300l.

- Material: Stainless steel

- Engine power, kW: 0,75

- Heating power, kW: 42

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 150l/ 200l/ 300l

- Voltage: 380-400V

These storage tanks are intended for fruit and vegetable juice storage and treatment. Price depends on your production process and the product.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 750 1000l/ 1500l 2000 2600 l/ 3000 4000 l/ 5000 l

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

- Built-in jacket for the bottom and walls of the unit.

- Cutter knives with a powerful electric drive

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

We offer different types of vacuum evaporation machines, this type is an affordable option for efficient evaporation in a stainless steel unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar