The device comprises a free-standing horizontal tank of cylindrical shape, the inner surface of the device is smooth, the angles are rounded, the welds are perfectly polished.

The device includes adjustable feet for uneven floors.┬ĀThe bottom is designed to ensure complete drainage of the tank. The design of the evaporator plates prevents the milk from freezing even with a small amount of milk.

Pressure tests of the device were performed at 60 bar. Functional pressure: 30 BAR. Fine insulation made of polyurethane foam friendly to the environment

- The device contains a mixing system with a SIREM motor - three-phase┬Āmixing blades with a speed of 21-25 rpm without joints for MPP

- Mixing motors are designed for easy cleaning

- The inclination of the evaporator and the milk outlet from the milk cooling tank according to the international standard (ISO 5708).

- Stainless steel dipstick and standard calibration chart.

- Flap closure made of stainless steel DN50),

- PVC lid and stainless steel chain

- Manhole ├ś500 mm

- Stainless steel ladder

- Washing pipe ├ś25 mm (recommended instead of spray heads as the head becomes clogged after some)

CONDENSING UNIT:

Compressor of the closed type condensing unit, the type of coolant is completely ecological. Also included is a solenoid valve, voltage and phase regulator (L1-L2-L3) to protect the electrical circuits of the tank against voltage fluctuations, high-pressure and low-pressure switches

TYPE OF INSULATION: INTERVOL RFN-24.

Two-component system made of rigid polyurethane foam. The blowing agent used is a mixture of HFCs. Density: 40 kg / m3 (DIN53420). Compressive strength: 20 kPa (DIN53421). Thermal conductivity, 24 ┬░ C: 0 023 W / m’é░K (DIN18164). Stainless steel dipstick(AISI 304) for easy and direct reading of volume in mm. Standard calibration chart

An option with a standard automatic control panel is available

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

You might also like

The Milk Cooler has a simple design, which allows for easy and safe operation. it meets the requirements of all dairy production facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 200l/ 300l

- Voltage: 380-400V

Cooling tunnel with a length of 15.2 meters. The standard design consists of 13 sections with removable top. For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

The KWS mixing vessel is engineered for versatile operations, including heating, cooling, and mixing of liquid products, with a maximum heating temperature of 60 ┬░C.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Geometric volume: 100 l

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitŌĆÖs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

Heating: electric and steam - combination

- Material: Stainless steel

- Principle of operation: Continuous mode

The vacuum crystallizer-cooler is specifically designed for sweetened condensed milk. Crystallization with cooling is one of the most important stages in the production of condensed milk according to GOST and is necessary before dosing and packing the finished product.

- After crystallization, condensed milk has a delicate structure with small crystals

- Condensed milk has a homogeneous shape and attractive consumer properties

- The shelf life of condensed milk is extended without changing the quality of the product

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

An air cooling conveyor is a system that uses moving belts and airflow to cool down products as they are transported along the conveyor line.

For additional information or a price quote, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 500 mm

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The Milk Cooler has a simple design, which allows for easy and safe operation. it meets the requirements of all dairy production facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 200l/ 300l

- Voltage: 380-400V

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

The water chiller CHWHE consists of a cooling unit in the upper part and a pump plus isolated water tank (made of stainless steel) in the lower section. We offer different capacities.

- Volume: 120 l/ 300l

- Voltage: 380-400V

The cooling units have a compact design. They are space-saving and easy to assemble. The chiller in standard version can work at water outlet temperatures from +10┬░C to +25┬░C.

For more information, send us an email to sales@normit.com┬Ā

- Volume: 18 l/ 30l

- Voltage: 220-230V

The vacuum diffusion cooling unit is a multifunctional device not only for vegan processors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The vacuum bread cooler is well-suited for application in small bakeries or as a laboratory unit in industrial enterprises. This enables the post-baking of bread under vacuum conditions, influencing both its shape and structure.

- Built-in deep vacuum system

- Built-in vapor removal and condensation system

- Built-in refrigeration system

- The chamber is designed for 3 gastro containers size GN 1/1, or pallets: 400x600/530x325 mm

- Compact and mobile installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 130l

- Voltage: 380-400V

Milk cooler tank designed for cooling milk and other dairy products. The tank is available in 13 different capacities, covering a range from 50 liters all the way up to 2,500 liters, capable of meeting the needs of all dairy & cheese production facilities. We offer 2 or 4 milking options. Prices are displayed for the milk cooling tank with 4 milking.

- Material: Stainless steel

- Principle of operation: Batch mode

The new line of NDJ refrigeration units is suitable as a cooling source for industrial applications operating with a closed coolant circuit. Efficient and reliable flow cooling of liquids

- Principle of operation: Continuous mode

- Country of origin: EU

This air cooler and heater is multifunctional. It can be used as air cooler, heater. The compact and lightweight air cooler / heater contains. 4 caster wheels make it easy to move the unit.

Lowering the temperature and humidity protects the product even without chemical treatment. The device is also used for continuous air cooling after heat treatment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

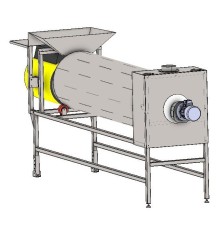

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1