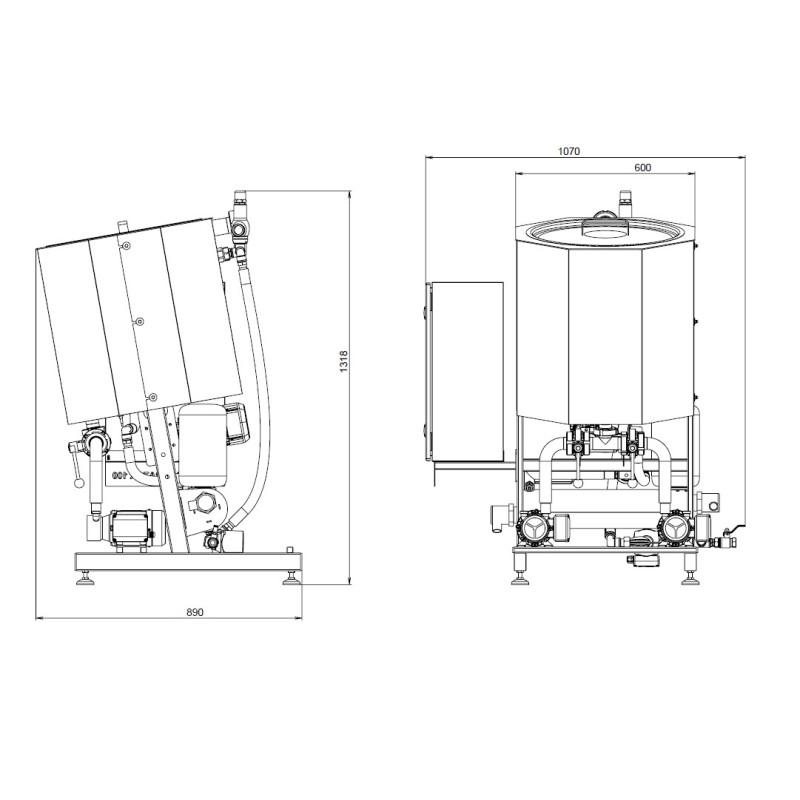

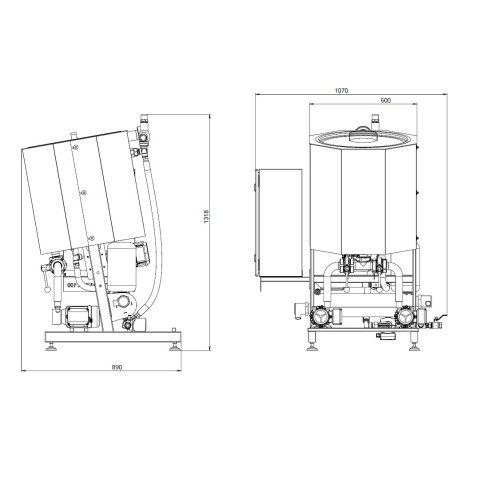

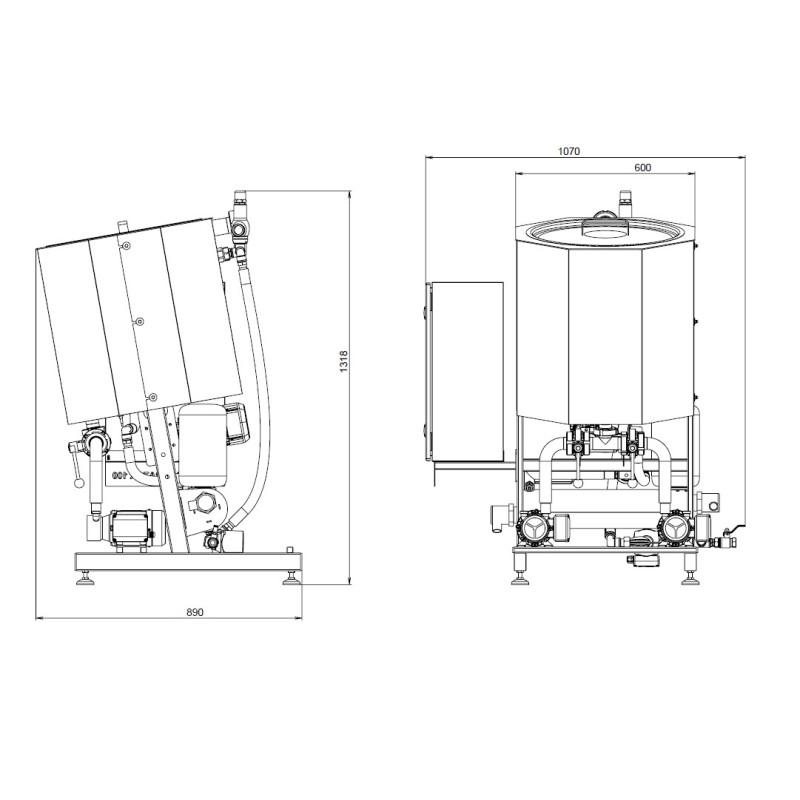

Tank with a mixer and jacket for the thermal carrier

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitŌĆÖs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

Atmospheric mixers with a frame stirrer and a jacket for the heat transfer medium (for heating or cooling) are suitable for use in the food, cosmetic, chemical, and many other industries, as they allow a wide range of processes to be performed, including:

|

|

|

|

|

|

|

|

|

Atmospheric tanks with a stirrer and a heating/cooling jacket are suitable for the production of such products as:

|

|

|

|

|

|

|

|

|

|

|

|

And much more!

Advantages:

- Hygienic design: virtually eliminates product contamination after washing, as there are no blind zones inside the reactor.

- No dead corners due to gravity mixing, the product flows to the lowest point, from where it is raised by the mixer and mixed into the total mass. Gravity mixing is 50% more efficient than usual. It allows intensive mixing, and the mixing of thick and viscous products.

- The inclined design of the unit also helps to quickly unload the product while the mixing device is on.

- The unit can be equipped with various types of frame mixing devices.

- The heating/cooling jacket up to 0.5 bar allows the use of steam or hot water as a heat carrier for heating, and if cooling is necessary, cold water or glycol can be supplied to the jacket.

- A professional stainless steel temperature sensor is installed in the bottom of the working tank, certified for use in contact with food products.

- Robust design, all components are supplied only from European manufacturers. All connections, joints, fittings are made only out of stainless steel AISI 304 and 316L, connections - fittings used in dairy processing from German manufacturers such as AWH. All connections have high-temperature Viton seals. The tanks are resistant to acids, alkalis and high temperatures.

- The internal surfaces are polished to RA Ōēż 1.6 ┬Ąm. Mirror internal surfaces (for the pharmaceutical industry) can be ordered as an option.

- Convenient maintenance due to the inclined design even with large installation volumes. Space saving in production facilities ŌĆō compact, high-performance tanks.

Basic version:

The basic version of the unit is equipped with a frame stirrer with a professional industrial three-phase gear motor. The reactor has a two-layer casing with a heating/cooling jacket (up to 0.5 Bar). Optionally, thermal insulation with an external decorative casing can be installed. In the basic version, the internal surfaces of the mixer are polished, the welds are cleaned and etched. Optionally, the internal surfaces of the mixer can be polished to Ra <0.4 ┬Ąm. Hot water or steam can be used as a heat carrier.

Options:

- A professional stainless steel temperature sensor in the product at the bottom of the tank with a control panel in the form of a temperature controller

- Various types of mixing devices

- Scrapers for the agitator

- CIP heads

- Hot water supply source

- Steam generator

- Ice water stations

- Thermal insulation with an external decorative casing

- And much more...

The images contain models with the maximum configuration, and are posted for informational purposes. Actual installations may differ from those shown.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

This open tank is intended for washing the juice tanks. Kapacity 250L.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Volume: 250l/

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

We offer different types of vacuum evaporation machines, this type is an affordable option for efficient evaporation in a stainless steel unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

ProfiCut is an ideal solution for efficient and economical processing of dressings, sauces, baby food as well as spreads, pat├® and processed cheese with advanced processing techniques.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Geometric volume: 500 l/ 800 l

The sorption filter 3000l refers to non-pressure equipment of periodic action for filtering liquids using bulk filtering agents and different sorbents.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 3000

These storage tanks are intended for fruit and vegetable juice storage and treatment. Price depends on your production process and the product.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 750 1000l/ 1500l 2000 2600 l/ 3000 4000 l/ 5000 l

A large stainless steel pot with a drain valve and a temperature sensor can be used on any cooking surface: electric, gas, induction.

- Large 6/4'' drain valve

- Multi-layer sandwich bottom

- Cooking pot wall thickness 1 mm

- Professional, high-temperature temperature sensor

- Material: Stainless steel

- Volume: 50l/ 100l/ 150l

- Diameter, mm: 400/ 500/ 600

The vacuum cooking and concentration unit is designed for concentrating products at low temperatures (about 60 degrees) in a reactor with a discharged environment to preserve the color, nutritional value and useful natural substances in present in food products. Evaporation and concentration units are often used when cooking jams, sauces, as well as fruit or vegetable concentrates. The vacuum concentrator allows you to boil and concentrate heat-sensitive products without damaging or destroying their structure or proteins, such as milk.

- Inclined design - allows for gravity mixing, which is 40% more efficient than usual

- Quick and 100% emptying of the tank thanks to the inclined design with the mixer on

- Heating/cooling jacket (duplicator) for the working tank and bottom

- High hygiene standard - the output valve is located at the lowest hydraulic point of the reactor

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 500l/ 875l

Specialized vacuum cooking kettle for sweet masses, ideal for commercial applications and medium to large scale food production.

For a price quote, send us a request.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l

- Dimensions, mm: 2055x1800x1980

The cylindrical conical tank is a designed for the fermentation of the beer and other beverages.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

It is ideal for cooking jams, marmalades, syrups, sauces, creams and other products.

Price depends on the chosen option.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

- Geometric volume: 350 l

The Economy series of the cooking kettles comprise a thick-walled stainless steel container with an electric mixer mounted on the quick-release upper housing. The installation allows you to mix and stir products during processing. The thick bottom of the pot allows it to be installed on all types of heating surfaces (gas, induction or electric stove).

The Economy version is recommended for use with low-viscosity liquid products; If processing thick and viscous products is necessary, we offer the Premium version of the cooking kettle.

- Sandwich bottom (multilayer) for use on all types of hobs, including induction

- Quick release lid with an electric stirrer

- Safety grid under the upper hull hatch - safe handling when stirring

- Possibility of visual inspection through the safety grid during processing

- Safe loading of components even during mixing

- Material: Stainless steel

- Engine power, kW: 0,12

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The vacuum batch dryer is suitable for gentle and high-quality dehydration to obtain a product with low solvent/moisture content.

- Special stirrer for uniform heat distribution and mixing

- Drying of heat-sensitive wet solids

- Suitable for the separation of suspensions and drying extracts

- Low processing temperature due to a deep vacuum

- Material: Stainless steel

- Volume: 300l/ 600l/