Fruit and vegetable transporting, washing, grinding and dosing equipment

Fruits or vegetables are placed into the input hopper. After soaking, the product is lifted while being sprayed with clearwater. Its main advantage lies in its mobility, as the washer doesn't require wheels.

Ideal for:

- fruit

- vegetables

- many other products

Washer with a grinder or washer and grinder with a dosing module

Two different versions are available. With or without the dosing module. The machine is easy to clean, with massive plastic modular elevator, steplessly adjustable speed in both ways, with 2pcs rotating, 2pcs fixed wheels.

Technical data

- Performance 1500 kg/h

- Electric demands: 3 kW

- Dimensions: 710 x 3200x2120 mm

- Output height: 1280 mm

- Weight: 200 kg

- Tub water capacity: 120 L/shift

- Washing water supply: 20-100 l/h depending

Features:

- IP65 certified electronics

- Grinder with a massive crushing hammer (available for beetroot and quince)

- Noise emission 60-70 dB

- Productivity: 1500 kg/h

- Material: Stainless steel

- Engine power, kW: 3

- Weight: 200

You might also like

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Dimensions: 2000x1230x1600

Volume: 150 l

Performance: up to 3000 kg/hour

Price on request.

- Productivity: do 3000 kg

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 150l

- Voltage: 380-400V

- Dimensions, mm: 2000x1230x1600

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

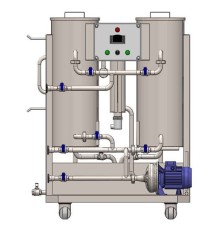

CIP-51: Equipment for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 50 liters

- Material: Stainless steel

- Country of origin: EU

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

Dimensions: 2000x1230x1600

Volume: 150 l

Performance: up to 3000 kg/hour

Price on request.

- Productivity: do 3000 kg

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 150l

- Voltage: 380-400V

- Dimensions, mm: 2000x1230x1600

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

- Material: Stainless steel

The destoner lift machine is designed for pre-washing and transporting root vegetables such as potatoes, carrots, beets, and other similar vegetables. After rinsing, the auger destoner separates floating particles like leaves and stems in the receiving hopper, while the product is conveyed up to the discharge height using a screw lift.

- Allows you to separate stones, leaves from root vegetables

- Pre-washing of root vegetable crops

- Two functions in one unit: washing and transporting

- Spacious hopper/tub for loading the product

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

CIP station CIP-101 With a usable capacity of 1├Ś100 liters, it is used for cleaning, sanitizing and sterilizing vessels and pipes in a brewery. This type of CIP station is recommended for cleaning and sanitizing tanks from 0 to 4000 liters.

- Material: Stainless steel

- Country of origin: EU

- Productivity: 300 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

Compact universal washing and spin-drying unit designed for gentle and effective cleaning of fruits and vegetables. The system combines adjustable whirlpool washing with centrifugal drying, allowing efficient removal of soil, dust, and water in just a few minutes. Constructed entirely from food-grade stainless steel, it ensures hygienic operation and easy cleaning. Ideal for restaurants, hotels, catering kitchens, and small food processors.

- Efficient combined washing and drying process - total cycle under 5 minutes

- Adjustable washing intensity for delicate or firm products

- Stainless steel perforated drum for thorough cleaning and durability

- Integrated spin dryer for quick water removal and extended product shelf life

- Compact, easy-to-clean design with low water and energy consumption

The CEP washing machine is a mobile cleaning station designed to efficiently clean various containers, including mixers and boilers, suitable for use in the food, chemical, and pharmaceutical industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

CIP-302: Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with two tanks of 300 liters.

- Material: Stainless steel

- Country of origin: EU