Fruit and vegetable washing and drying machine Turbo 90

Compact universal washing and spin-drying unit designed for gentle and effective cleaning of fruits and vegetables. The system combines adjustable whirlpool washing with centrifugal drying, allowing efficient removal of soil, dust, and water in just a few minutes. Constructed entirely from food-grade stainless steel, it ensures hygienic operation and easy cleaning. Ideal for restaurants, hotels, catering kitchens, and small food processors.

- Efficient combined washing and drying process - total cycle under 5 minutes

- Adjustable washing intensity for delicate or firm products

- Stainless steel perforated drum for thorough cleaning and durability

- Integrated spin dryer for quick water removal and extended product shelf life

- Compact, easy-to-clean design with low water and energy consumption

The fruit and vegetable washing and drying machine is a universal solution for washing a wide range of fresh produce.

It is used for cleaning and drying delicate lettuce and herbs, as well as firm products such as carrots, potatoes, and apples. The controlled whirlpool water circulation system effectively cleans the produce while minimizing mechanical damage.

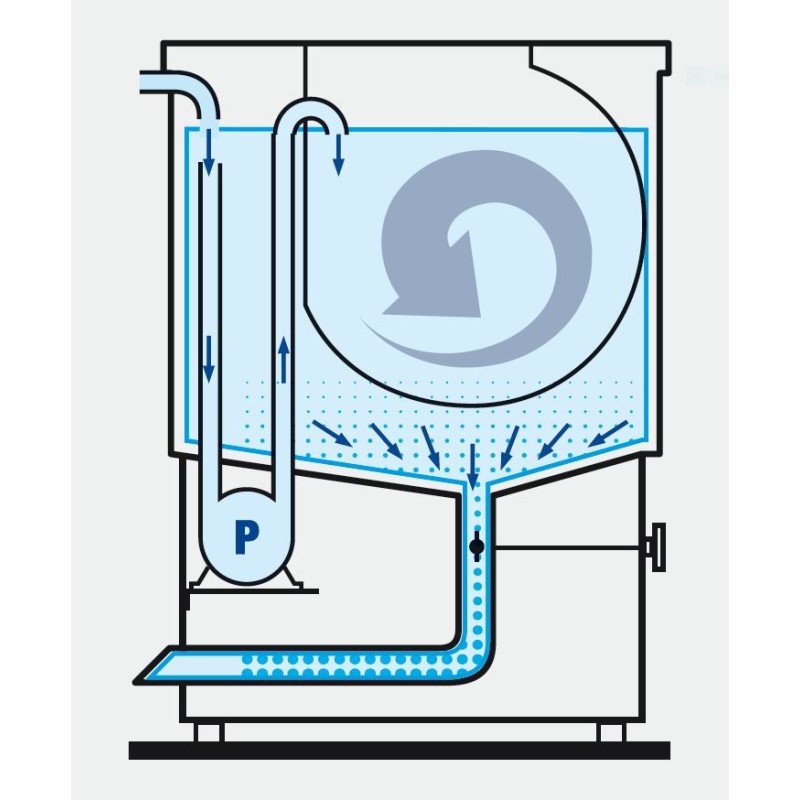

The washing process takes place in a perforated stainless steel drum immersed in water. A circulation pump creates a rotating water flow, generating a gentle whirlpool effect that efficiently removes soil and impurities from the product surface. The water remains clean thanks to continuous flow and drainage through the drum holes.

After the washing cycle, the cleaned product is spun in the integrated centrifugal dryer, where rapid rotation removes excess moisture within one minute. This significantly reduces dressing dilution in salads and improves the final product quality for further processing or packaging.

The system achieves water savings and a bacterial load reduction of over 90%, ensuring both hygienic and economic operation.

Advantages

- Adjustable whirlpool washing system suitable for both leafy and heavy vegetables

- Stainless steel drum with perforated sides and bottom for effective washing and drainage

- Fast, efficient spin drying without product damage

- Simple mechanical structure and easy operation with intuitive controls

- High hygiene level, all parts in contact with the product are made out of polished AISI 304 stainless steel

- Minimal water consumption and easy cleaning with a removable drum and outlet components

- Self-braking safety system automatically stops rotation when the lid is opened

Basic version

The basic configuration includes:

- Washing tank with perforated stainless steel drum

- Electric water circulation pump (0.4 kW) with adjustable washing intensity

- Integrated spin dryer with a removable plastic basket and transparent lid

- Manual control panel with washing and drying start/stop buttons, and washing/drain regulation knobs

- Adjustable legs for stable positioning

- Low-voltage control system with a safety microswitch

- Electrical protection class IPX4

- CE compliant, manufactured in accordance with EN 60335-1 and EN 60335-2-64

Operating principle

- The vegetables or fruits are placed into the washing drum filled with water.

- The circulation pump creates a whirlpool effect, rotating the product gently for 2ŌĆō4 minutes.

- Dirt and impurities are separated from the product and drained through the perforations.

- The cleaned product is then placed in the spin-drying basket.

- Centrifugal force quickly removes remaining water, achieving surface drying in about one minute.

- This process ensures high-quality washing and drying while preserving a fresh product appearance.

Applications

- Leafy vegetables (lettuce, spinach, herbs)

- Root vegetables (carrots, potatoes, beets)

- Fruits (apples, pears, citrus)

- Processed or peeled vegetables before packaging

- Small-scale meat, fish, and deli processing (optional use)

Technical characteristics

| Washing cycle | 2ŌĆō4 minutes |

| Drying cycle | approx. 1 minute |

| Washing capacity | up to 15 kg per cycle |

| Drying capacity | approx. 1 kg |

| Drum volume | 90 L |

| Power consumption | 1 kW |

| Voltage | 1~230V / 50 Hz |

| Dimensions (L├ŚW├ŚH) | 1000 ├Ś 600 ├Ś 910 mm |

| Net weight | 135 kg |

| Water inlet diameter | 1/2ŌĆØ |

| Drain diameter | 1 1/4ŌĆØ |

| Rotation speed (rpm) | 750 |

Optional equipment

- Automatic water level regulator

- Sanitizing agent dispenser

- Additional baskets for continuous operation

You might also like

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

The cutting machine is designed for slicing, shredding and grating fruits and vegetables.

- Productivity: 500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Dimensions, mm: 602x488x1581

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Productivity: 300 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with four tanks.

- Heating: Electricity Steam

- Material: Stainless steel

- Voltage: 380-400V

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V

Our tunnel container washers are designed to wash different kinds of plastic containers.

- Material: Stainless steel

- Heating power, kW: 15/ 20

- Principle of operation: Continuous mode

- Voltage: 380-400V

CIP-302: Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with two tanks of 300 liters.

- Material: Stainless steel

- Country of origin: EU

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

This machine allows washing and sterile rinsing with dry steam of cans and cups before filling them with product.

- Productivity: 6000 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

Dimensions: 2000x1230x1600

Volume: 150 l

Performance: up to 3000 kg/hour

Price on request.

- Productivity: do 3000 kg

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 150l

- Voltage: 380-400V

- Dimensions, mm: 2000x1230x1600

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

- Material: Stainless steel

Clean-in-place (CIP) is a method of cleaning and disinfecting the internal surfaces of pipes, containers, water tanks as well as industrial equipment, filters, related fittings and other accessories without the need for disassembly.

- Material: Stainless steel

- Volume: 2x50 l/ 2x100 l/

Bubble washer for gentle washing and cleaning of fruits and berries, for example peaches, cherries, strawberries and other raw fruits prior to their further processing.┬Ā

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 600 mm/ 800 mm/ 1000 mm

CIP station CIP-101 With a usable capacity of 1├Ś100 liters, it is used for cleaning, sanitizing and sterilizing vessels and pipes in a brewery. This type of CIP station is recommended for cleaning and sanitizing tanks from 0 to 4000 liters.

- Material: Stainless steel

- Country of origin: EU

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode