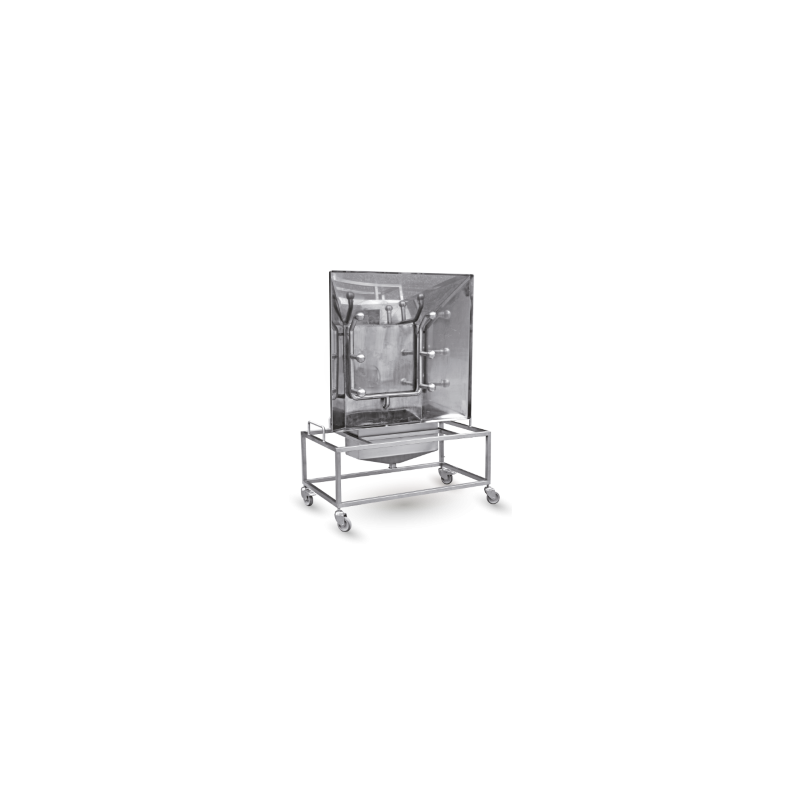

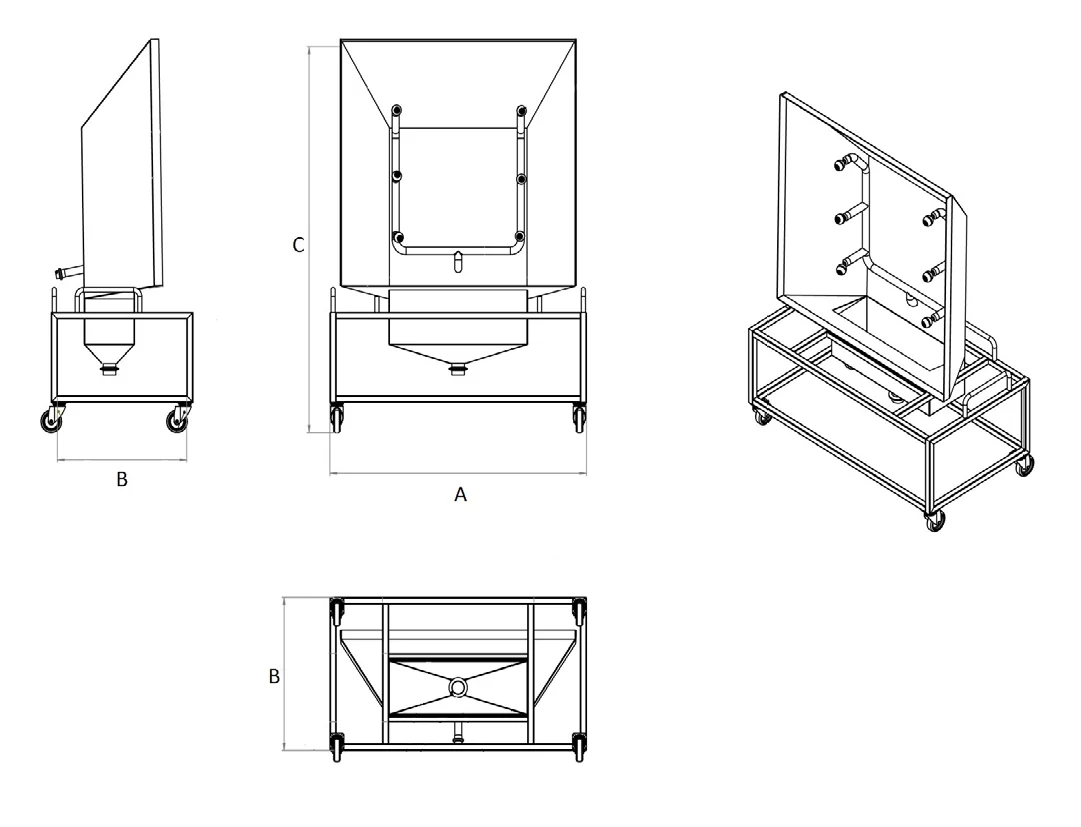

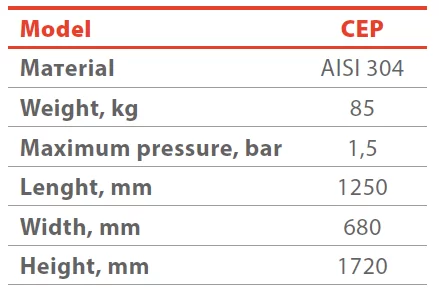

Vessel washer CEP

The CEP washing machine is a mobile cleaning station designed to efficiently clean various containers, including mixers and boilers, suitable for use in the food, chemical, and pharmaceutical industries.

Vessel washer CEP is designed for cleaning various containers - for example a z-blades mixer, which can be tilted.

The washer also allows for the use of steam. The device is equipped with spray nozzles for rinsing water. Mobile washing equipment for washing of various mixers with tilting bowl, boilers, kneaders and other similar equipment. The device for washing the vessel is a mobile device equipped with a tilt system in the horizontal state. The device is equipped with nozzles for supplying water to the container in a tilted position.

Areas of use:

- food industry

- chemical industry

- pharmaceutical industry

Advantages:

- Has a return bath, several CIP heads, the screen can be hermetically locked with the washing equipment.

- Universality - is applicable for a wide range of products

- The device is completely made of stainless steel

- High efficiency and productivity

- Automatic temperature control

- Low water consumption

- Full safety when using

Allows on-site fast and convenient conduct of high quality hygienic processing of various equipment, as well as scalding with steam.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

You might also like

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

Vegetable washers are designed to clean and prepare vegetables for consumption or further processing.

We offer different types of vegetable washers.

- Material: Stainless steel

- Engine power, kW: 0,47 / 1,45 / 1,85

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 160 l/ 300l/ 600l/

This machine allows washing and sterile rinsing with dry steam of cans and cups before filling them with product.

- Productivity: 6000 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Volume: 200l

Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with four tanks.

- Heating: Electricity Steam

- Material: Stainless steel

- Voltage: 380-400V

We offer different types of washing equipment for various different fruits and vegetables.

- Productivity: 1500 kg/h

- Material: Stainless steel

- Engine power, kW: 3

- Weight: 200

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

Wheat washer, huller and separator is used for the preparation of grain for milling. Price depends on your production capacity.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

We offer a wide range of washing equipment tailored to diverse food products, ensuring optimal cleanliness and preparing your fruits and vegetables for the next processing stage.

- Productivity: 2000 kg/h 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

Bubble washer for gentle washing and cleaning of fruits and berries, for example peaches, cherries, strawberries and other raw fruits prior to their further processing.┬Ā

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 600 mm/ 800 mm/ 1000 mm

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1