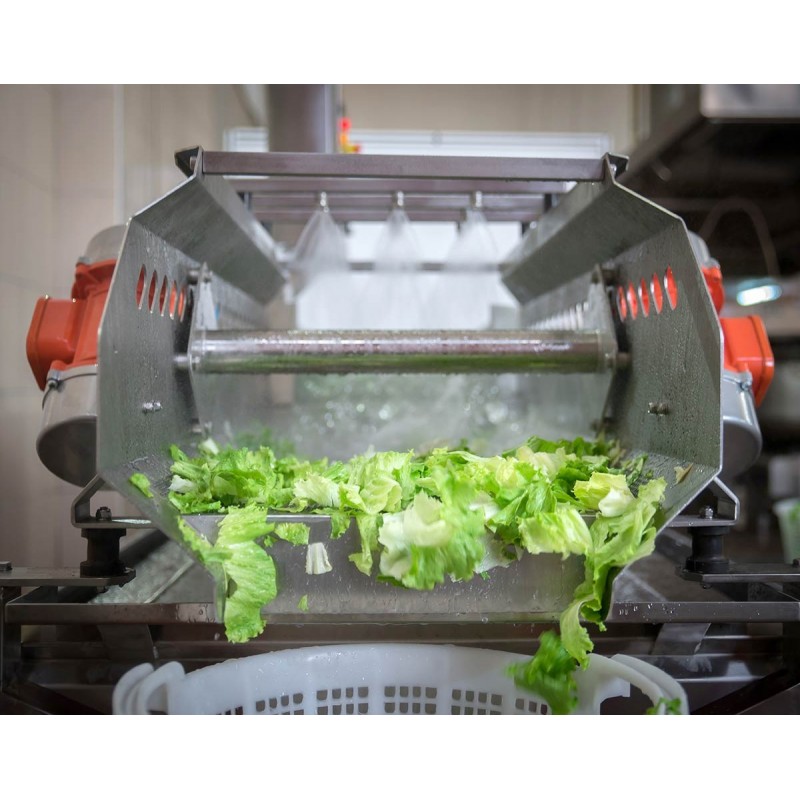

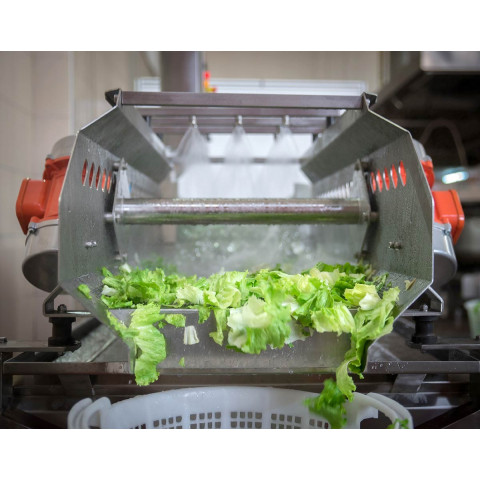

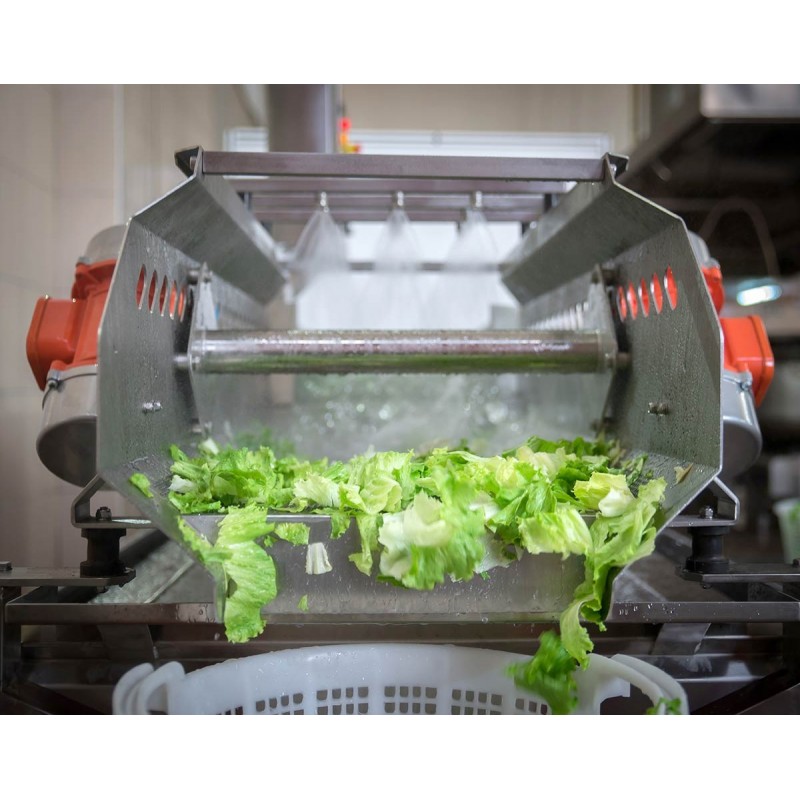

Vibrating washer with a conveyor

The vegetable washing machine with vibrating conveyor is designed for continuous operation by continuous feeding.

Vegetable washing system

The products entering the machine continuously rotate around themselves and also the washing chamber with the effect of the high pressure water,then going about 10 meters and fall to the vibration conveyor .High pressure in the washing chamber ensure excellent hygienic- bacterial condition and perfect washing results . The clean water coming from the rinse nozzles is used instead of the dirty water discharged from the system. Machine works continuously with clean water.

Ideal for:

- fruits

- vegetables

- many other products

Washing Capacity

- Light Vegetable: 300 kg

- Heavy Vegetable and Fruits: 600 kg

Bacterial Hygienic Washing

The product passes from washing chamber to the vibrating conveyor during this operation product also washed by 9 fresh water nozzles. Disinfection of the products is ensured with the help of the pump connected to the disinfectant inlet.

Filter

Unwanted particles, dirt and sand , which are separated from the product in the washing chamber, pass through the filter in the bottom of the chamber and enter the sinking channel. Since the water in this channel is stable they can not mix with the washing system and they leave the system through the discharge valve. The channels at the upper limit of the washing chamber is designed to automatic discharge of the unwanted particles and insects.

Technical features:

- Power: 3,5 kW

- Electrics: 220-380 V AC ŌĆō 50 Hz

- Weight: 420 kg

- Washing chamber water capacity: 750 lt

- Clean Water Inlet: 1/2ŌĆØ

- Water Discharge: 2ŌĆØ

- Dimension: 3100x955x970/1550 mm

- Productivity: 300 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

You might also like

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Dimensions: 2000x1230x1600

Volume: 150 l

Performance: up to 3000 kg/hour

Price on request.

- Productivity: do 3000 kg

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 150l

- Voltage: 380-400V

- Dimensions, mm: 2000x1230x1600

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

Vegetable washers are designed to clean and prepare vegetables for consumption or further processing.

We offer different types of vegetable washers.

- Material: Stainless steel

- Engine power, kW: 0,47 / 1,45 / 1,85

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 160 l/ 300l/ 600l/

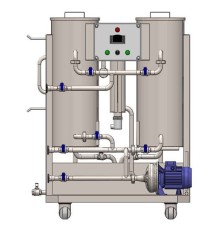

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

CIP-302: Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with two tanks of 300 liters.

- Material: Stainless steel

- Country of origin: EU

We offer different types of washing equipment for various different fruits and vegetables.

- Productivity: 1500 kg/h

- Material: Stainless steel

- Engine power, kW: 3

- Weight: 200

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Volume: 200l

The washer-auger-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

Price depends on your product and the production capacity. For more information, send us a request.

- Productivity: 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

This machine allows washing and sterile rinsing with dry steam of cans and cups before filling them with product.

- Productivity: 6000 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

CIP-102 consists of two main tanks for alkaline and acid solution and one vessel used for neutralization of solutions.

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 100l

- Voltage: 380-400V

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V

The container washer for canned food is a specialized washing system designed to thoroughly clean containers used for canning food products, ensuring hygiene and sanitation standards are met within your food processing facility.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Vegetable washers are designed to clean and prepare vegetables for consumption or further processing.

We offer different types of vegetable washers.

- Material: Stainless steel

- Engine power, kW: 0,47 / 1,45 / 1,85

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 160 l/ 300l/ 600l/

Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with four tanks.

- Heating: Electricity Steam

- Material: Stainless steel

- Voltage: 380-400V

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

The CEP washing machine is a mobile cleaning station designed to efficiently clean various containers, including mixers and boilers, suitable for use in the food, chemical, and pharmaceutical industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

- Material: Stainless steel

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V