Vacuum homogenizer VMG NS 300-650

The price is indicated for the basic version of the vacuum reactor without additional options, the final cost depends on the modifications

The vacuum homogenizer is an ideal solution for the production of food, for example mayonnaise, it is also suitable for the cosmetics industry - the production of toothpaste. This model of the homogenizer is based on a vacuum reactor with an external homogenizer and an external circulation circuit, the parameters of which are selected as options.

- Tilted design - 25% more efficient mixing

- Easily disassembled reinforced frame mixer, for thick and viscous products

- Jacket for the coolant around the bottom and walls of the working reactor

- The vacuum reactor can withstand a vacuum up to -0.8 Bar

- A large number of options to choose from to suit various requirements

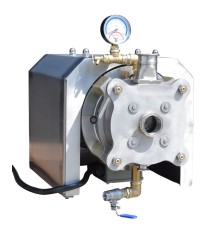

The vacuum homogenization system is equipped with an integrated homogenizer inside the working chamber; such models also include VMG homogenizers. An alternative to these homogenizers is found in vacuum reactors with a built-in Ultra Shear type inline homogenizer placed in an external circulation loop. This solution significantly expands the equipment's capabilities, enabling the connection of an inline homogenizer to other installations and utilizing the vacuum reactor for cooking, mixing, or vacuuming (deaeration) of the finished product. Moreover, the external circulation circuit enhances the efficiency of stirring, mixing, and homogenizing products with various mediums, including solid inclusions, uniformly distributing them throughout the entire product mass.

Undoubtedly, this feature also enhances the overall versatility of the system. The homogenizer's power and pump type can be independently selected and easily replaced without impacting the reactor's structure, making the installation more adaptable. Typically, this solution is also more cost-effective.

The NS series vacuum reactor is a universal installation used for mixing and the heat treatment of various products. When equipped with a homogenizer and a circulation circuit, the Inline reactor can be used as a homogenizing unit for the production of a wide range of liquid, paste and viscous products (emulsions, suspensions in the pharmaceutical, food, cosmetic and chemical industries) requiring careful uniformization and homogenization.

|

|

|

|

|

|

|

|

|

|

Advantages:

- Capable of processing a wide range of liquid, paste, viscous, and highly viscous products.

- The mixer is positioned at an angle, allowing it to cover the entire working space of the container and providing multidirectional mixing of the product in horizontal and vertical planes. Gravity mixing harnesses the force of Earth's gravity, allowing the processed product to flow and self-collapse along the container walls into the lower part of the working container, where a quickly-detachable frame mixing device picks it up and blends it into the overall mass.

- The mixing device is quickly detachable, which makes it easy and convenient to use.

- The basic version of the upper reactor housing is equipped with bolts for removing the cover (only during maintenance work). A hatch is located on the upper housing for convenient servicing during reactor operation and use.

- Another advantage of the equipment is the vacuum, which ensures the removal of air and guarantees the maintenance of high product quality due to lower processing temperatures.

- Another important feature of the new homogenizer is that the product is loaded through the top cover, which can be opened completely.

- Internal seams are sanded smooth.

- The reactor is equipped with a âjacketâ for the coolant around the bottom and side body of the working tank with a pressure of up to 0.5 Bar, which avoids uneven heating/cooling and dead zones during heat transfer.

- Reliable design and long-term trouble-free operation.

- Quick transition to new types of products.

- Easy operation, maintenance and sanitation.

- Low noise level.

- Low acquisition costs for purchasing equipment suitable for beginner entrepreneurs, ideal for developing new recipes and the production of medium to large batches of products.

- Wide range of additional options.

Basic version

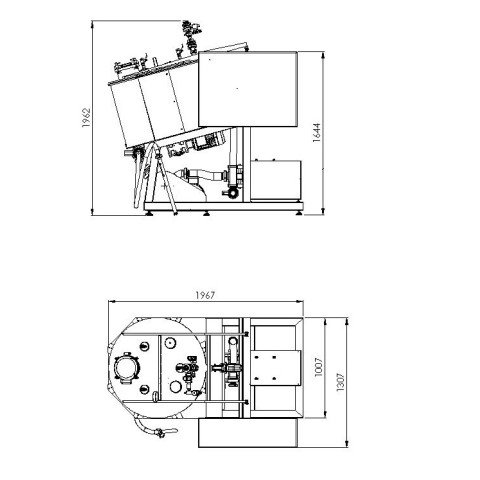

The installation consists of an inclined working container mounted on a supporting structure (frame). The working tank is equipped with a 4-layer casing with a âjacketâ or duplicator for the coolant and an external hygienic decorative casing. The basic version of the device is equipped with a frame mixing device with an electric drive and a hatch on the upper body of the unit. As an option, it can come equipped with a top cover that opens using linear actuators, teflon scrapers for the frame mixing device, a product recirculation system with a disperser/homogenizer and a pump. The basic version of the control unit includes a frequency converter for a soft start as well as the adjustment of the rotation speed of the mixing device, and a thermal controller with a temperature sensor.

Processes:

|

|

|

|

*-from an external source

When retrofitting the installation with an optional inline homogenizer in the external circulation circuit (option), it is also possible to perform processes such as:

|

|

|

Options:

- Mixing device scrapers made out of fluoroplastic

- Lid lifting system with linear actuators

- External circulation circuit with a pump

- Inline homogenizer Ultra Shear

- Vacuum generation system

- System for holding and adjusting the vacuums depth

- CIP heads for washing (rotary)

- Hopper system with a pipework system and shut-off valves

- Automatic component dosing system controlled via an industrial controller with a touchscreen

- Reinforced drive for the mixing device

- Hot water source

- Ice water station

- And much more!

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 650l

- Total power, kW: 0,55

- Voltage: 380-400V

- Max vacuum: -0,8 Bar