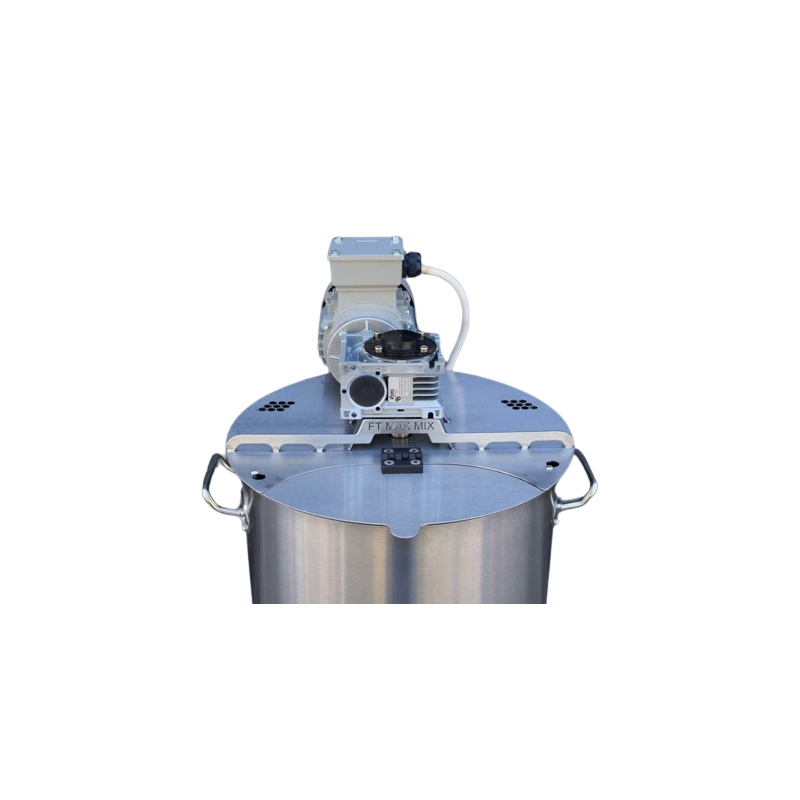

High speed mixing tank TurboMix

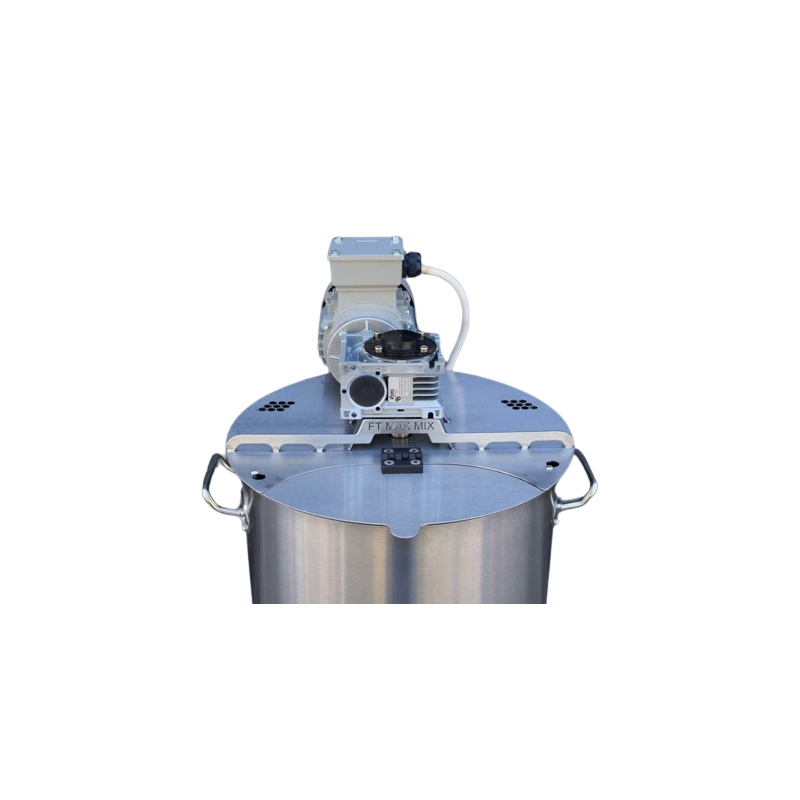

A universal vessel for mixing, whipping and stirring any products using a blade mixing device operating at high speeds.

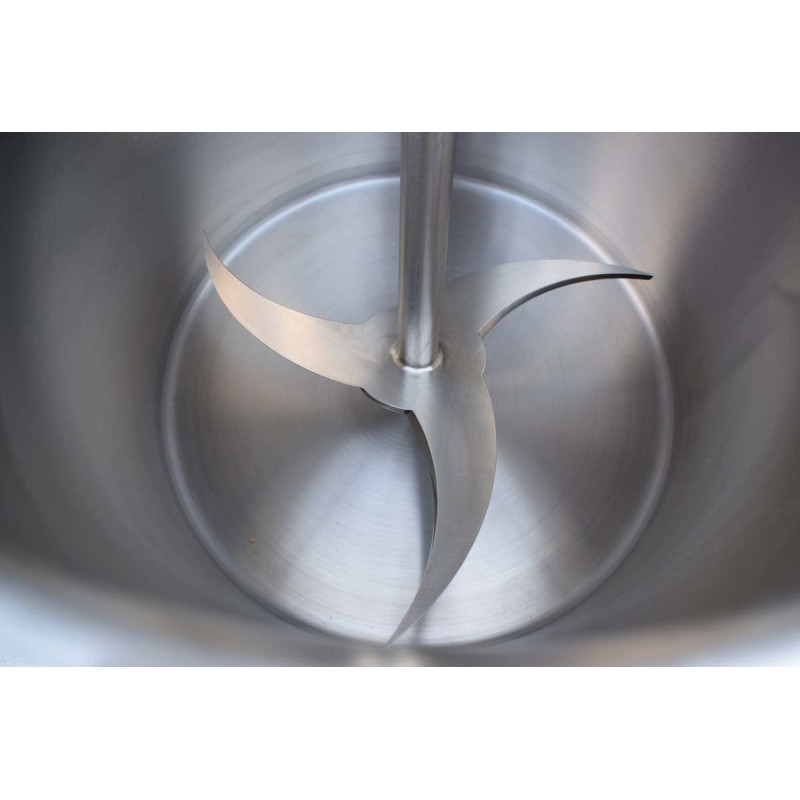

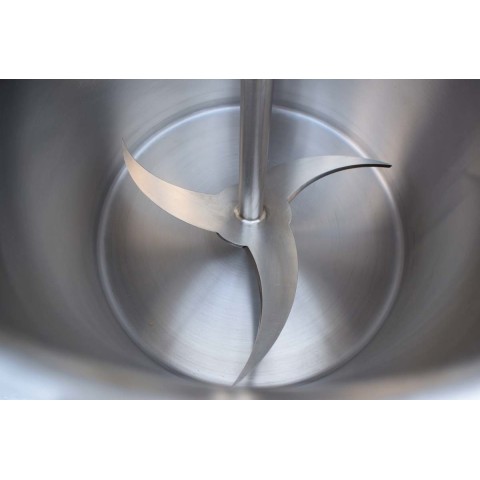

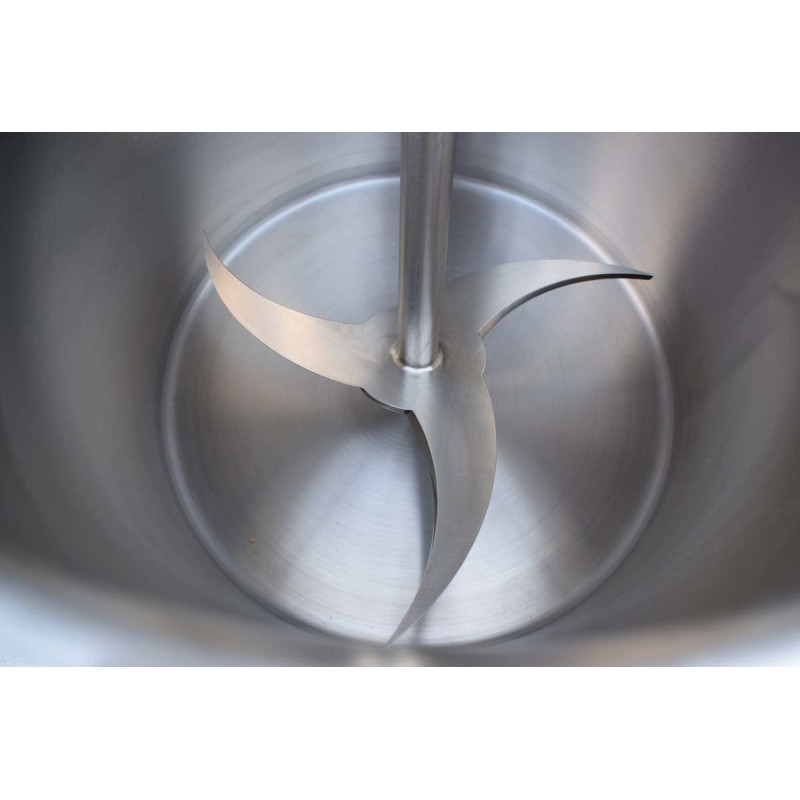

- Crescent shaped mixing device with three sharpened blades (cutter knives)

- Special high speed drive

- Sandwich bottom for all types of heating surfaces (electricity, gas, induction).

A mixer such as this, is one of the main devices utilized in large kitchens and catering facilities as well as small scale food production. This mixer with a high-speed stirrer allows for quick and efficient mixing of various liquid products to obtain solutions, multicomponent mixtures, dissolving powder ingredients in a liquid medium as for example, for the production of marinades.

Due to the fact that the mixing vessel has an additional option in the form of a heating source - an electric heating stool, mixing can be carried out simultaneously with the continuous thermal processing of the products.

With TurboMix you can easily mix products such as:

|

|

|

|

|

|

Advantages:

- High speed drive for cutting knives

- A special shape of the cutter knives on the mixing device, which effectively mix the product and prevent it from sticking to the bottom of the working container while effectively mixing a wide variety of ingredients

- Can be used with different types of heating surfaces for even more effective mixing, dissolving and stirring

- An easily removable lid with a stirrer for easy unloading of the finished product; just open two latches and remove the stirrer from the container.

- Safety grid - under the sectional opening lid there is a special grid with holes for safe visual monitoring of the process or adding small, liquid or bulk ingredients during operation.

Basic version

TurboMix is a stainless steel container with a wall thickness of 1 mm and a bottom thickness of 5 mm, which houses a specially shaped mixing device for effective mixing of components with a high rotation speed of the cutter's knives. The mixer is equipped with a quick-release lid that opens in sections for visual control of the process, it is also equipped with a safety mesh.

Additional options

Vertical mixing blade for mixing especially thick and sticky products.

Heating surfaces:

- electric "stool"

- gas burner

- Productivity: 50l/ 100l

- Material: Stainless steel

- Engine power, kW: 0,18/

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Diameter, mm: 400/ 500/ 600

You might also like

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

The 5 kw stool-type electric heating stove with a diameter of 40 cm is designed to heat large pots and pans with a volume of up to 100 liters.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Type of the equipment: Optional equipment

The durable single gas stove serves a versatile purpose, suitable for heating large cooking kettles. 7 kW.

- Heating: Gas

- Heating power, kW: 7

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

Atmospheric cutter mixer with capacity of 150l for medium size production of confectionery, chocolate, ice cream, ready meals, cheese, cream smoothie, vegetable puree.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 150l

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

The NDM + drum mixer is designed for thorough mixing while retaining the structure of loose products without dead zones and with relatively low consumption and short mixing time. Made for mixing products such as coffee, tea, nutrients and supplements, baby food and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

Suitable for mixing a small amount of dough or meat as well as other thick mixtures.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

Butter churner with a volume of 50 L and a usable volume of 25 L for the traditional production of butter from cream.

- Material: Stainless steel

- Engine power, kW: 0,55

- Geometric volume: 50 l

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

The mixers are made up of a double-walled cylindrical stainless steel vessel with cavity, with drain hole and 50 cm diameter butterfly valve. The cavity is filled with water which is heated by an electric resistance thermostat. The honey is mixed by blades with a marine propeller profile, adjustable in height along an oblique shaft.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55/ 1,1

- Principle of operation: Batch mode

- Volume: 100 kg / 250 kg/ 600 kg/ 1000 kg/ 2000 kg

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

Planetary mixers are primarily used in the confectionary industry. Offered in three different capacities.

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

These meat tumblers are designed for removing air and drawing moisture and marinade into the meat under the conditions of a vacuum.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 600l/ 900/ 1200l/ 2000 3000

The laboratory vacuum cutter mixer is designed for uniform grinding, emulsifying and mixing of food, cosmetic and pharmaceutical products, chemical mixtures with the addition of oil, dyes, concentrates or liquid flavors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

A spiral mixer with a fixed bowl and an electronic control panel. Available in various different capacities.

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 120 l/ 160 l/ 200l/ 250 l

- Voltage: 380-400V

Tilting atmospheric cooking kettle is designed for homogeneous cooking and mixing of sauces, smoothies, jams, spreads, soups, pasta, yoghurts, ice cream, curd desserts, mousse, air confectionery masses, pastry cream, fillings for sweets, waffles, rolls, chocolate, gingerbread, cookies, muffins, rolls, pastilla, marshmallows, meringues, marshmallows, brewed dough, sponge cake.

For a price quote, send us a request.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Voltage: 380-400V

- Geometric volume: 330

- Dimensions, mm: 1700x1030x1500

Paddle Mixer type is designed for fast and precise mixing for meat-mass production in meat processing factories. Can also be used for mixing products such as spices or tea.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 90/ 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 2000 3000