The machine is air-driven and is designed for filling and capping flexible pouches (those with an existing spout) containing liquid or semi-liquid products. It utilizes a volumetric piston filler with a dosing range of 50-1300 ml, and seals the pouches with plastic screw caps of the same size.

All components in contact with the product are manufactured out of AISI 316 L stainless steel and food grade gaskets. The cap is tightened by a pneumatic motor with torque regulation.

This unit can fill viscous products containing soft particulates or fibers and is suitable for hot filling (100┬░C).

Technical features

Production: maximum production up to 500 pieces/hour of 90 ml volume pouches, depending on the operators speed.

The main frame of the machine is made out of stainless steel AISI 304, and is mounted on wheels. All equipment components that come in contact with the product, including the shaft, are made out of stainless steel AISI 304. The filling & capping machine has a manual pouch positioning.┬Ā

Single head capping:

- Air consumption is around 250 Nl/min.

- Requirements: air compressed 2├Ę6 bar.

Filling unit consists of:

Volumetric dosing unit from 50 to 1300 ml, AISI 316 L stainless steel

- Food grade set of gaskets

- Three way rotary valve

- Pneumatic two way no drop valve with a switch off nozzle

- Food grade flexible hose

- Hose tail that connects the unit to the storage tank

Single head capping unit consists of:

- Pneumatic motor

- Stainless steel chuck for one size of plastic screw cap

- Manual control for adjusting the height of the equipment

- Nitrogen injection unit

HOW IT WORKS

The machine operator places the pouch on the collar and, using a hand-wheel control, adjusts the filler to regulate the product filling capacity. Both filling speed and suction can be finely tuned to meet highly specific requirements. Upon manually moving the lever, the filling valve starts operating, and the employee initiates the filling process with a button press.

As the filling process nears completion, the machine injects nitrogen into the empty space of the pouch. This step expands and preserves the product, effectively extending its shelf life. The injection time and flow of nitrogen can be precisely adjusted using the pressure regulator. Following this, the employee places the cap on the spout, positions the closing head in the capping position through the lever mechanism, and manages the cap tightening process to ensure proper sealing.

OPTIONS

- S/steel collar for holding another spout size and shape

- S/steel custom made chuck for 1 size of plastic screw cap

- Surcharge for 200-5000 ml filling range (instead of 50-1300

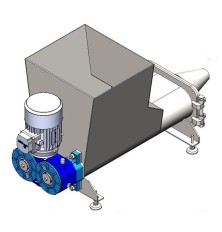

- 15 liters AISI 316 conical hopper

- 30 liters AISI 316 conical hopper

- Material: Stainless steel

- Operation mode: Semi-automatic

You might also like

Semi automatic packaging machine for filling and capping jars.

For additional information, please contact us at┬Āsales@foodtechprocess.com

- Material: Stainless steel

4 Heads vacuum bottle filling machine serves as a professional semi-automatic filling and dosing machine for filling glass bottles with various fluids.

For additional information, please contact us at┬Āsales@foodtechprocess.com

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

Semi-automatic dosing machine, designed for filling and capping different spouted pouches with various liquids.

- Material: Stainless steel

- Operation mode: Semi-automatic

The piston filler is designed for dosing different types of liquid products in the food, chemical, pharmaceutical and cosmetic industries.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

A range of pneumatic vertical filling machines for dosing liquids with viscosity is similar to water.

- Type of the equipment: Individual machine

The pneumatic piston filler for pastes and liquids is a semi-automatic dispenser designed for dosing various liquids with a low, medium or high viscosity.

- Tabletop compact model

- Includes a built-in 26 l conical storage tank

- A wide dosing range from 300-2500 ml

- Can also be used for products with a high degree of viscosity

- High dosing speed

- Possibility of working in manual or automatic mode

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 300-2500 ml

- Voltage: 220-230V

Cost-effective system for filling barrels on the basis of a scale for filling the product with a pump.

For more information, please contact our sales department at sales@foodtechprocess.com

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

For more information about the product please contact the sales department at sales@foodtechprocess.com

We sell different types of dosing machines, for more information, send us an email to sales@foodtechprocess.com

- Material: Stainless steel

- Engine power, kW: 0,18/

- Operation mode: Automatic

- Country of origin: EU

- Voltage: 220-230V

This head capping machine has a magnetic clutch, ribbed spindle. It is semi-automatic and closes bottles or jars with PFP aluminum caps, twist off caps or plastic screws. The price depends on the cap, product you are filling, and capacity.

For more information or a price quote, please email us at sales@foodtechprocess.com

- Productivity: 400-700 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Automatic Bag-in-Box filler intended for filling the bag-in-box bags with finished products (both hot and cold) - with a bag volume of 3 to 20 liters.

- Productivity: 180 -240 psc/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

A filling machine for stuffing meat to make sausages. We offer many different dosing machines for different applications.

For more information, send us an email at sales@foodtechprocess.com

- Material: Stainless steel

- Operation mode: Manual

- Weight: 27/ 28/ 30

- Dimensions, mm: 710x280x390 / 790x280x390 / 820x280x390 /

We offer different types of meat stuffing machine for domestic and commercial use.

For more information, send us an email to sales@foodtechprocess.com

- Weight: 10 / 12

- Dimensions, mm: 630 x220x230 / 820x220/230

A simple mobile filler is an economically advantageous solution for filling barrels. We also offer barrel top filler.

For more information, contact our sales department at sales@foodtechprocess.com

Semi automatic packaging machine for filling and capping jars.

For additional information, please contact us at┬Āsales@foodtechprocess.com

- Material: Stainless steel

VBF is a fast, robust, and versatile vacuum bottle filler.┬ĀThis is the filling machine you are looking for if you desire to increase the production volume of your homemade products, and professionalize the bottling of wine, oil, beer, fruit juices, or other products.

To get the price quote, contact us at sales@foodtechprocess.com

Designed for accurate feeding and packaging of liquids under pressure.

For a price quote e-mail us at sales@foodtechprocess.com

Filling and capping machine designed for the filling and capping of liquid or semi-liquid products into flexible doypack bags with a spout.

- Material: Stainless steel

- Voltage: 220-230V

TEPF is a pneumatic dispenser for dosing several kind of products. The machine allows the filling of food, chemical, cosmetic, or pharmaceutical products into diverse type of bottles and jars.

Price depends on the product used. For more information, send us an email to sales@foodtechprocess.com

- Material: Stainless steel

- Operation mode: Automatic Manual

- Type of the equipment: Individual machine

We sell many different filling machines for different products. For more information, send us an email to sales@foodtechprocess.com┬Ā

- Material: Stainless steel

- Country of origin: EU

A filler is a device designed for dosing and pumping honey. It guarantees comfortable and professional honey processing.

For more information, please contact our sales department at sales@foodtechprocess.com