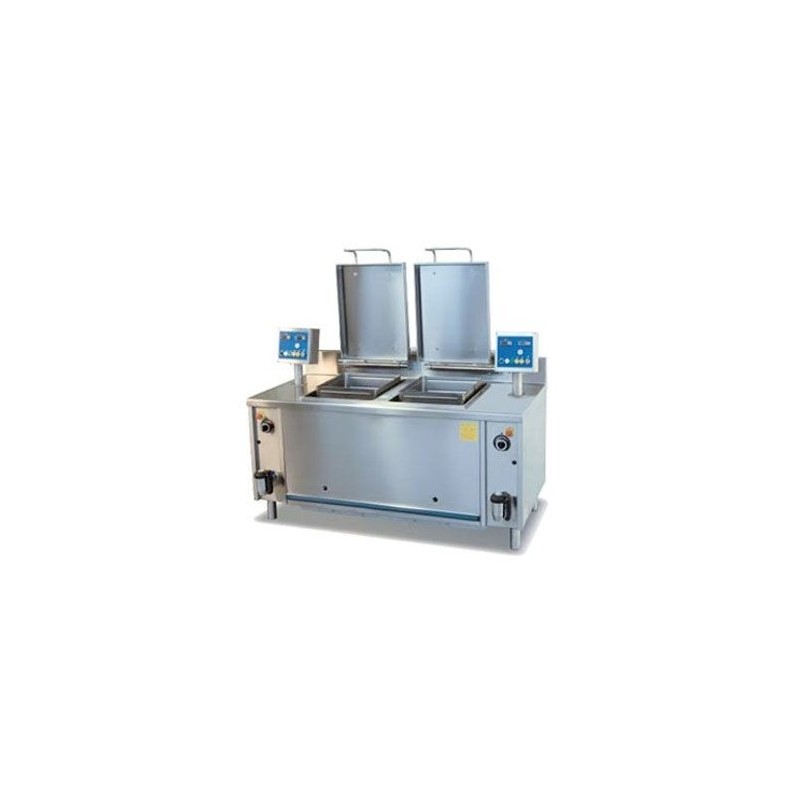

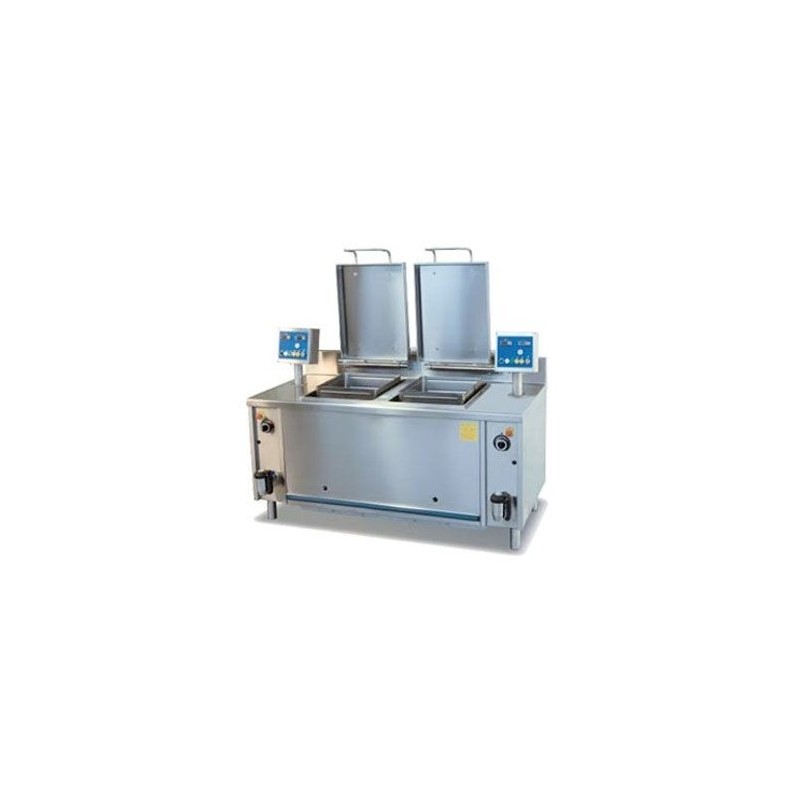

Automatic double-basket cooking boiler

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

Automatic multi-functional double-basket cooker which helps you to process different types of products. Compact, easy to use, and presents excellent results.

General features:

- 6 models from 2x135l to 2x220l

- Quick to clean, guaranteeing high-level hygiene thanks to the satin-finished surfaces

- Simple to inspect thanks to the removable front panel providing access to the technical compartment

- Thermally insulated with high-density 96/128 kg/m3 bio soluble fiber felt featuring excellent thermal stability and which significantly reduces heat dispersion

- Delicate treatment of all food types, at the service of the Chef

- Adjustable balanced lid, perfect to prevent condensate from dripping into the tank

- Thick, anti-corrosive materials ensure the sturdiness and resilience of the pot over time

Cooking tank

- Tank completely in satin-finished AISI 316 stainless steel

- Baskets in satin-finished AISI 316 stainless steel

- Overflow device and starch skimming and discharge valve

Lid

- The lid is made in AISI 304 15/10 stainless steel, featuring a chrome-plated steel hinge with pre-loaded spring and a thermal handle.

- Gauge to control pressure inside jacket

- Manual relief valve to depressurize the jacket during heating

- Adjustable mixer in chrome-plated bronze with hot and cold water

- Weight-loaded safety valve calibrated at 0.5 bar

Frame, panels, and supporting structure

- Supporting structure in 20/10 stainless steel mounted on adjustable steel leveling feet from 150mm to 180mm

- External walls in AISI 304 10/10 stainless steel with a satin finish

- The satin-finished ledge in AISI 304 15/10 stainless steel

Basket tilting system

- Automatic tilting system by means of electric actuator

- Possibility to adjust the position of the basket to drip and drain, or alternatively direct front draining

- Power supply 400V 3N 50Hz

Heating system options:

Direct gas

- Ignition by means of manual piezo igniter and pilot flame

- Heating by means of high-performance tubular burners in AISI 304 stainless steel

- Ventilation grille

- Set of nozzles for various types of gas

- Tap with safety valve with thermocouple

- Safety thermostat to protect against overtemperature and lack of water

Indirect steam with jacket

- Heating by means of steam (from user mains) with solenoid throttle valve allowing a gradual steam intake in the jacket

- Control of pressure in a jacket by means of safety valve calibrated at 0.5 bar, manual vacuum relief valve, and pressure gauge

Direct electric

- Heating by a series of heating elements

- Heating element safety thermostat with heating block due to overtemperature or insufficient water level

- Temperature control (50¬įC ‚Äď 120¬įC)

- Standard power supply 400V-3N-50Hz

Specifications:

|

HEATING |

MODEL |

CAPACITY      lt. |

DIMENSIONS L x P x H mm |

BASKET DIMENSIONS  mm |

Power   (kW) |

CONSUMPTION |

||||

|

Gas |

Electric |

G.P.L. kg/h |

Metano H m3/h |

Metano L m3/h |

Vapore kg/h |

|||||

|

DIRECT     GAS |

MCP 30.G |

135 + 135 |

1800x900x900 |

2 x (480x650x565) |

2 x 24 |

0,2 |

3,78 |

5,08 |

5,92 |

- |

|

MCP 40.G |

220 + 220 |

2500x1000x900 |

2 x (720x800x565) |

2 x 39 |

0,2 |

6,16 |

8,26 |

9,60 |

- |

|

|

STEAM BOILING |

MCP 30.V |

135 + 135 |

1800x900x900 |

2 x (480x650x565) |

- |

0,2 |

- |

- |

- |

2 x 70 |

|

MCP 40.V |

220 + 220 |

2500x1000x900 |

2 x (720x800x565) |

- |

0,2 |

- |

- |

- |

2 x 100 |

|

|

DIRECT   ELECTRIC |

MCP 30.E |

135 + 135 |

1800x900x900 |

2 x (480x650x565) |

- |

2 x 13,7 |

- |

- |

- |

- |

|

MCP 40.E |

220 + 220 |

2500x1000x900 |

2 x (720x800x565) |

- |

2 x 25 |

- |

- |

- |

- |

|

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

The gas cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. This cooking equipment is not suitable for roasting or baking.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 80l/ 100l/ 150l/ 200l/ 300l

The cream-cooking kettle with manual tilting is designed for controlled heating, concentration, and thermal treatment of cream and cream-based products. Its adjustable temperature control, gentle handling, and uniform heat distribution enable processes such as thickening, reduction, pasteurization, and the preparation of dessert bases.

- 6-stage heating intensity adjustment

- Uniform heat distribution for a consistent product consistency

- Manual tilting system for complete and convenient emptying

- Suitable for cream, dairy desserts, sauces, and similar products

- Smooth stainless steel interior for easy cleaning and maintenance

Thanks to the indirect heating system, this kettle is ideal for cooking liquid dishes. It is completely made of stainless steel and equipped with a convenient drain valve.

- Material: Stainless steel

- Heating power, kW: 18

- Voltage: 380-400V

Double-jacket stainless steel cooker for marmalade and jam production.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

You don't need professional equipment or special skills to brew beer at home; all you need is to buy a spacious kettle with an automatic stirring device!

- Special mixing device prevents malt from sticking to the bottom.

- The cooking kettle has two side handles for easy manipulation.

- The kettle, lid, and outlet valve are made entirely of stainless steel.

- The beer kettle can be used on any stove or you can purchase an electric base along with the kettle (optional).

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

The electric kettle with a stirring device and manual tilting is suitable for a wide range of applications in food production or professional kitchens. It has an independent frame and built-in intensive electric heating with a wok-shaped, multi-layer ‚Äúsandwich‚ÄĚ base, allowing the heating temperature to reach up to 200 ¬įC.

- High processing temperatures of up to 200 ¬įC

- Built-in, powerful 2,6 kW / 6,5 kW electric heating

- Manual tilting and unloading system with three working positions, allowing a maximum tilt angle of 110¬į

- Professional high-temperature thermometer with a probe in the product

- Air insulation of the outer casing

- Stirring device with stainless steel scrapers for high-temperatures

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

Heating: electric and steam - combination

- Material: Stainless steel

- Principle of operation: Continuous mode

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 220l/ 500 l

This kettle is designed to be used by catering companies, canteens, restaurants, small productions and food manufactures.

- Heating: Steam

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

This automatic cooking machine is made for continuous production. Different types of food can be boiled, like pasta, rice (minimum 1.5 mm in size), vegetables, meat etc., thanks to the basket’s design.

- Material: Stainless steel

- Operation mode: Automatic

- Volume: 300l/ 600l/

- Voltage: 380-400V

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 250l/ 300l

Price depends on the chosen option. Please send us a request.

- Heating: Electricity Steam

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l

- Dimensions, mm: 1070x1120x1040

It's compact cooking equipment for catering and gastronomic sphere: cafes, bars, canteens. The cooking equipment is designed for boiling, stewing, frying and mixing products of different viscosity.

Specialized vacuum cooking kettle for sweet masses, ideal for commercial applications and medium to large scale food production.

For a price quote, send us a request.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l

- Dimensions, mm: 2055x1800x1980