Automatic commercial cooking equipment

This automatic cooking machine is made for continuous production. Different types of food can be boiled, like pasta, rice (minimum 1.5 mm in size), vegetables, meat etc., thanks to the basket’s design.

Automatic pasta cooker with one tank suitable for cooking pasta, vegetables, meat and many other products

Different types of food can be boiled, like pasta, rice (minimum 1.5 mm in size), vegetables, meat etc., thanks to the basket’s design. Setting the cooking parameters is intuitive and easy and with the precision instruments. The cooking results are excellent and cycles can be repeated by simply pressing the start button.

COMMERCIAL KITCHEN EQUIPMENT - TECHNICAL FEATURES

- Supporting frame in stainless steel thickness 20/10.

- The external panel in stainless steel AISI 304 fine satin finish.

- Cooking tank in stainless steel AISI 316/L and fine satin finish SB, thickness 25/10.

- Top thickness 15/10

- Perforated and tilting baskets made of stainless steel AISI316

- Thermal insulation guaranteed by high-density ceramic fiber 64/128.

- Jacket with bottom and walls in stainless steel AISI 304

- Balanced Lid made in stainless steel AISI 304, with heat resistant handle

- Automatic lifting and tilting of baskets by electric actuator mechanism with the possibility of positioning the basket, by means of a selector, for product dripping or direct front discharge

- Front drain tap made of 2‚ÄĚ chrome-plated brass with an insulating handle

- Overflow device and automatic starch skimming

SUITABLE FOOD THAT CAN BE PROCESSED

- Pasta

- Rice

- Broths

- Legumes

- Vegetables

- Meat

- Fish

- Eggs

Automatic cooking machine with tilting container

- Automatic tilting by electric actuator mechanism with the possibility for positioning, by means of selector, to drip product or to drain directly

- Electric power supply: 400V 3N 50Hz

Pasta cooker with heating system

- Direct Gas versions

- Heating by means of AISI 304 stainless steel high-efficiency tube burners

- Ignition by means of manual piezo-electric lighter and pilot flame

- Valve-controlled safety tap with thermocouple

- Safety thermostat against overheating and lack of water

- Venting grid

- Set of jets for different types of gas

Indirect Electric versions - Automatic cooker with Jacket

- Heating by means elements in INCOLOY alloy, separated from the cooking yield

- Safety thermostat to prevent overheating and keeps the equipment from operating without water

- Jacket pressure control by working pressure switch and weight-loaded safety relief valve calibrated 0,5 bar, vacuum valve and pressure gauge

- Jacket water level control taps max/min with the option of automatic filling

- Standard power supply 400V - 3N - 50Hz

Professional cooking equipment - Direct Electric versions

- Heating with electric heaters

- Safety thermostat to prevent overheating and keeping the equipment from operating without water

- Temperature is controlled by thermostat (50¬įC - 120¬įC)

- Electric supply 400V 3N 50Hz

- Material: Stainless steel

- Operation mode: Automatic

- Volume: 300l/ 600l/

- Voltage: 380-400V

You might also like

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

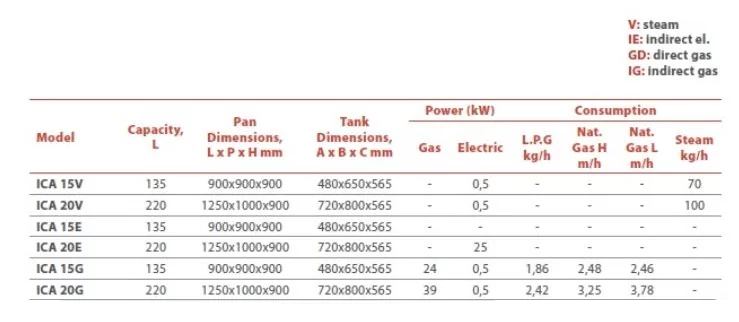

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

A milk pasteurizer is designed for quick and effective pasteurization of milk, where the heating of the product in the working container is achieved by supplying hot water into the jacket.

- Special mixing device

- Large outlet valve at the lowest point of the pasteurizer

- Insulation of the working container to reduce heat loss during pasteurization

- Compact installation

- The control panel is located directly on the unit's body

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 300l

The gas cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. This cooking equipment is not suitable for roasting or baking.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 80l/ 100l/ 150l/ 200l/ 300l

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

This 265 liter stainless steel cooker is great for boiling or roasting a variety of ingredients. It is made of stainless steel and equipped with a convenient drain valve.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

We sell many different types of cooking equipment, with a mixer or without, tilting cookers, with capacities from 100 - 350 liters.

- Material: Stainless steel

- Country of origin: EU

Chocolate heating pump is the perfect solution to upgrade your production line. You can easily connect the pump to any device (such as a chocolate enrobing machine).

- Principle of operation: Batch mode

- Voltage: 380-400V

Automatic tilting cooking pots, with lateral support upright designed for cooking solid foods that are transferred by tipping of the container. Options: steam boiling, indirect electric, indirect gas, direct gas. Capacity options: 50, 100, 150, 200, 300, 500l.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Volume: 50l/ 100l/ 150l/ 200l/ 300l/ 500l

- Voltage: 380-400V

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

- Material: Stainless steel

- Volume: 60l/

- Voltage: 380-400V

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 220l/ 500 l

These gas boiling cookers are manufactured for professional kitchens and also for other food processing factories. This is 150l capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

The Steam Cooking Pot allows you to cook large batches of your signature soups, stews and pasta as well as steaming and boiling of semi-finished products.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 400l

The vacuum cooking and concentration unit is designed for concentrating products at low temperatures (about 60 degrees) in a reactor with a discharged environment to preserve the color, nutritional value and useful natural substances in present in food products. Evaporation and concentration units are often used when cooking jams, sauces, as well as fruit or vegetable concentrates. The vacuum concentrator allows you to boil and concentrate heat-sensitive products without damaging or destroying their structure or proteins, such as milk.

- Inclined design - allows for gravity mixing, which is 40% more efficient than usual

- Quick and 100% emptying of the tank thanks to the inclined design with the mixer on

- Heating/cooling jacket (duplicator) for the working tank and bottom

- High hygiene standard - the output valve is located at the lowest hydraulic point of the reactor

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 500l/ 875l

The GHE boiler can be used in butchery, smokestack, fruit preserving, etc. It is used for cooking soups, sauces, meat, pasta, dairy meals without the risk of burning, for stewing fish, vegetables, mushrooms, for heating frozen meals or semi-finished products.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24/ 30/ 36/ 42

- Principle of operation: Batch mode

- Volume: 85l/ 100l/ 150l/ 200l/ 300l/ 400l/ 500l

Heating: integrated electric. Price depends on the production capacity and product.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

Double-jacket stainless steel cooker for marmalade and jam production.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

A professional cooking boiler with built-in intensive bottom heating and a tilting system for the working container allows you to quickly heat the product to high temperatures (200¬įC). Suitable for blanching, boiling, frying and stewing various products where high-temperatures and efficient processing is required.

- Powerful bottom heating with uniform heat distribution (2600 / 6500 W)

- Professional stainless steel probe in the product with a thermometer for visual control

- Compact standing supporting structure for safe operation

- Three-stage adjustment of the tilt angle of the working container

- The unit is made entirely out of stainless steel

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3,5/ 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l