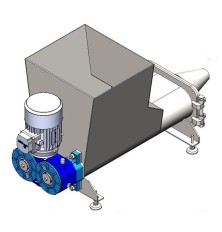

Chocolate dispenser ICCD 65

Chocolate fountain attracts the attention of customers thanks to its stylish design, and can be used to top ice cream cones, to fill cups with hot chocolate drinks etc. Price is for the machine only. You can purchase additional mobile counter, covering rings or various nozzles.

Chocolate dispenser machine designed for cake, ice cream and chocolate shops

ICCD is a chocolate dispenser invented specifically for cake, ice cream and chocolate shops. ICCD chocolate fountain attracts the attention of customers thanks to its stylish design, and can be used to top ice cream cones and tubs, to fill cups with hot chocolate drinks, to make pretty decorations etc.

Chocolate dispenser with different chocolate nozzles for various effects

You can personalise ICCD chocolate dispenser machine by choosing different nozzles, each with a distinctive effect. The nozzle can be changed in just a few seconds, for a different chocolate impact, and to ensure clients have a varied and interesting experience in your shop.┬Ā

Mobile counter available

ChocoHot Two chocolate fountain is encased in stainless steel with a pedal to control the chocolate flow, reversible and removable screw conveyor to make it easy to clean, changeable nozzles with different chocolate flow effects. Night-mode to keep chocolate melted and to keep consumption under control when the equipment is not used. Five special nozzles and mobile counters available.┬Ā

Specifications

- bath capacity: version ONE: 5.5 kg, version TWO: 2x5.5 kg

- voltage: 110/220 V

- power: ONE: 0.95 kW, TWO: 1.90 kW

- weight: ONE: 37 kg, TWO: 65 kg

- dimensions: ONE: 39x46x83 cm, TWO: 74x46x83 cm

What is chocolate dispensing machine for

- melted chocolate

- chocolate topping for ice cream

- chocolate topping for cakes

Optional accessories for chocolate dispenser:

- hole covering rings

- mobile counter

- different size nozzles

- Material: Stainless steel

- Voltage: 220-230V

You might also like

This machine is used to produce sweets coated with chocolate.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 7l/ 16

- Voltage: 220-230V

This machine is made for the production of coated sweets. This can include roasted sugar around almond nuts.

For more information, send us a request.

- Material: Stainless steel

- Engine power, kW: 0,17/ 0,37

- Principle of operation: Batch mode

- Voltage: 220-230V

The tempering machine for chocolate is manufactured in 3 different volumes, 100l, 200 and 300l.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

Chocolate flaking machine for automatically differentiating two blocks of couverture each time. The flakes are collected in plastic baking for food. The machine comes with two plastic bins.

- Productivity: 30 kg/h

- Material: Stainless steel

- Voltage: 220-230V

Chocolate tempering machine provides fluidity in the chocolate at all times and a perfect union of crystals.

- Engine power, kW: 1,5 /

- Weight: 80 / 120

- Volume: 12 kg / 24 kg

VBF is a fast, robust, and versatile vacuum bottle filler.┬ĀThis is the filling machine you are looking for if you desire to increase the production volume of your homemade products, and professionalize the bottling of wine, oil, beer, fruit juices, or other products.

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

- Material: Stainless steel

- Engine power, kW: 0,18/

- Operation mode: Automatic

- Country of origin: EU

- Voltage: 220-230V

Hydraulic piston fillers for the food processing industry, filling machines for meat and sausages, ideal equipment for meat industry producers and butchers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 20l/ 30l/ 50l

A filler is a device designed for dosing and pumping honey. It guarantees comfortable and professional honey processing.

- Material: Stainless steel

- Engine power, kW: 0,18

- Voltage: 220-230V

Designed for accurate feeding and packaging of liquids under pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 80l/

The device is designed for filling Bags In Boxes. Suitable for filling hot non-viscous products. The device can be purchased separately or with additional options - trolley and magazine.

- Material: Stainless steel

- Operation mode: Automatic

We offer different types of meat stuffing machine for domestic and commercial use.

- Weight: 10 / 12

- Dimensions, mm: 630 x220x230 / 820x220/230

Filling and capping machine designed for the filling and capping of liquid or semi-liquid products into flexible doypack bags with a spout.

- Material: Stainless steel

- Voltage: 220-230V

This head capping machine has a magnetic clutch, ribbed spindle. It is semi-automatic and closes bottles or jars with PFP aluminum caps, twist off caps or plastic screws. The price depends on the cap, product you are filling, and capacity.

Price depends on the lid, the product you are filling, and the container.

- Productivity: 400-700 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Compact digital filling machine for accurate dosing of viscous liquids such as honey, pastes, sauces, and oils. Designed with food-grade materials, easy-to-clean components, and precise digital control, it is ideal for small production, workshops, and laboratories.

- Operation mode: Semi-automatic

The pneumatic piston filler for pastes and liquids is a semi-automatic dispenser designed for dosing various liquids with a low, medium or high viscosity.

- Tabletop compact model

- Includes a built-in 26 l conical storage tank

- A wide dosing range from 300-2500 ml

- Can also be used for products with a high degree of viscosity

- High dosing speed

- Possibility of working in manual or automatic mode

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 300-2500 ml

- Voltage: 220-230V

The piston filler is designed for dosing different types of liquid products in the food, chemical, pharmaceutical and cosmetic industries.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

The honey dosing machine is a precise filling machine with a gear pump, it is easy to use and is suitable for filling honey as well as a large number of other different liquids - ranging from thinner ones such as drinking yogurt, to high-viscosity products such as mustard.

- Fast operation

- Easy to use

- Easy to clean

- Accuracy

- Compact design

- Productivity: 200 l

The piston-operated pneumatic liquid dispenser is a semi-automatic filler used for dispensing various low viscosity liquids ranging from 10 to 100 ml in volume.

- Compact tabletop installation

- Simple control with two operating modes: manual and semi-automatic

- Suitable for liquid products with low viscosity (from water to oil)

- Optional compressed air compressor available

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V