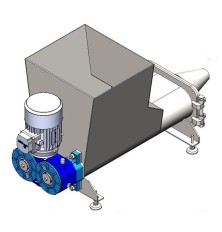

Open impeller centrifugal pump EDW 200

Centrifugal impeller pumps are ideal for various industrial applications such as food processing, manufacturing, washing and surface treatment of metal pieces, boxes, containers, glass jars and vessels. These pumps are also suitable for dishwashers, bottle washing lines, painting processes, and pumping liquids into various chambers.

For more information, send us an email to sales@foodtechprocess.com

Centrifugal pumps with an open impeller are particularly well-suited for washing vegetables, meat, fish, molluscs and similar products.

The electric centrifugal surface pumps feature a molded AISI 304 stainless steel body crafted through the hydroforming process, utilizing water pressure to deform the material. This ensures the highest quality standards, minimizes welding points, shapes the pump body efficiently, and allows for working with thick steel for maximum construction strength.

Equipped with an open radial flow impeller, this pump is well-suited for handling liquids with solid particles up to 19 mm in diameter, making it ideal for applications such as food washers, car washes, and industrial dishwashers. The standard mechanical seal is made out of Ceramic/Carbon/NBR, alternate versions with special seals are available as well.

Centrifugal pumps - Range of applications

- Max. Working Pressure: 8 bar

- Max. Liquid Temperature: 80┬░C

- Passage of Solid Substances up to 19 mm

Impeller water pump - Material

- Pump body, disc for the mechanical seal, impeller and shaft in AISI 304

- Aluminum flange and motor housing

- Mechanical seal made out of carbon/ceramic/NBR

- Special seals on request

Technical data:

- Total head from 17.5 to 5.1 m

- Capacity from 6 to 66 m3/h

- IE3 high efficiency motors starting from 0.75 kW

- Liquid temperature: from -5┬░C to +90┬░C (from -15┬░C to +110┬░C for H, HS, HW and HSW versions)

- Liquid with solids up to 19 mm in diameter

- Two-pole asynchronous motor with ribbed housing

- Class F insulation

- Degree of protection IP55

- Single-phase voltage 230V +- 10% 50 Hz

- Three-phase voltage 230/400V +- 10% 50 Hz

- Built-in capacitor and motor thermal overload protection with automatic restart for single-phase motor

- Overload protection for a three-phase motor is ensured by the user

- DNM 2"

You might also like

One of advantages of this glandless pump is very high durability and efficiency in operation in very demanding conditions. We offer glandless pump with different power variations.

For more information send us an email at sales@foodtechprocess.com

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

For more information, send us an email to sales@foodtechprocess.com┬Ā

Stainless steel low-speed rotary pumps with a flexible impeller; We offer two versions. On base or trolley.

If you need more information, send us an email to sales@foodtechprocess.com

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

For a price quote, send us an email to sales@foodtechprocess.com

Stainless steel low-speed rotary pumps with a flexible impeller; We offer two versions. On base or trolley.

If you need more information, send us an email to sales@foodtechprocess.com

We offer different types of pumps for different processes. For more information, send us an email to sales@foodtechprocess.com┬Ā

- Engine power, kW: 0,37

- Dimensions, mm: 230x190x120

This system is specifically designed for facilitating the direct transfer of pulp to a press.

- Productivity: 2000 kg/h

- Engine power, kW: 0,37

- Weight: 28

- Type of pump: Volumetric, self-priming

Centrifugal pump designed for pumping low viscosity food and aggressive liquids. For more information, send us an email to sales@foodtechprocess.com┬Ā

Vane pumps are used for pumping high viscosity products such as syrups, honey, mayonnaise, sauces, cream and many other products.

For more information about the product contact sales department at sales@foodtechprocess.com

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of pump: rotary vane

One of advantages of this glandless pump is very high durability and efficiency in operation in very demanding conditions. We offer glandless pump with different power variations.

For more information send us an email at sales@foodtechprocess.com

The fruit mash pump is designed for efficiently transporting mashed fruits from a crusher to a press for extracting juice.

- Productivity: 6000 kg/h

- Material: Stainless steel

- Engine power, kW: 1,85

- Voltage: 380-400V

Designed for pumping hot thermal oil in frying circulation and filtration systems, for oil loading and unloading, in "hot" continuous oil filtration systems with a maximum temperature of up to 200 degrees.

More information: sales@foodtechprocess.com

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

For more information, send us an email to sales@foodtechprocess.com┬Ā

The lobe rotary pumps are designed for pumping both liquid and thick products. We offer┬Ālobe pumps in 2 versions with┬Ā1.5 kW is a standard for milk, cream and similar products,┬Āand 3 kW is for dense low-flow products such as honey, pastes, cottage cheese etc.┬Ā

For more information, contact our sales department at sales@foodtechprocess.com

We offer different types of pumps for different applications.

For more information, send us an email at sales@foodtechprocess.com┬Ā

The pump provides a delicate straight-streaming┬Āpumping of a wide range of liquids with or without solid fragments with viscosity up to 150 Pa.s.┬Ā

For a price quote, send us an email to┬Āsales@foodtechprocess.com

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

Progressive cavity pumps are used to transfer low and high viscosity products as well as products containing soft particles. They are available in three sizes.

For more information on the pumps or for a quote, contact our sales department at sales@foodtechprocess.com

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

For more information about the product please contact the sales department at sales@foodtechprocess.com

The portable vertical pump is designed for pumping fluent or viscous liquids in the range from 1-2300 m2/s at a temperature of around 25┬░C. The pump cannot be used in potentially explosive atmospheres.

For more information or a quote, contact our sales department at sales@foodtechprocess.com