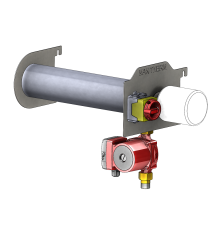

Expansion tank for the heating system

The expansion tank is an additional component of the heating system circuit, where flow-through electric heating is used as an independent closed system for heating the hot water, serving as a heat transfer medium circulating in the duplicator of food cooking boilers, reactors, pasteurizers, and other food processing equipment. In heating systems with water heaters operating at temperatures up to 110┬░C, the expansion tank is necessary to accommodate the increased volume of the heat transfer medium as it expands when heated.

- Special high-pressure vessel ŌĆō allows to withstand pressure of up to 5 bar in the system.

- Allows the use of a heat generator with superheated water up to 110┬░C.

- Has different volume options, depending on the volume of the heat transfer medium, selected additionally.

The expansion tank is used in heating systems with superheated water up to 110┬░C for heating the thermal medium in the heating jacket (duplicator) of various cooking boilers, reactors, evaporators or pasteurizers.

A special expansion tank in the form of a high-pressure vessel is necessary to regulate the volume of water in a closed system during heating. The tank also helps maintain the pressure level in the system.

- Type of the equipment: Optional equipment

You might also like

A flow-through water heater is a device for flow-through electric heating of water in heating systems for cooking boilers, evaporators and other units where it is necessary to supply a hot heat transfer medium - superheated water - to the heating jacket (duplicator). When choosing a flow-through heater, it is necessary to select a circulation pump based on the volume of the jacket or heat transfer vessel.

- The heater allows you to heat water up to 110 degrees

- Easily integrated into heating systems

- Has heating temperature regulation

- 2 stages of heating power adjustment

- Independent control panel with protection against overheating and "dry" running

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2/ 3/ 6/ 9/ 10/ 12

- Principle of operation: Continuous mode

The circulation pump for the heating system is a mandatory component for the operation of a flow-through heating system used for heating the water serving as a heat transfer medium inside the duplicator of industrial cooking boilers, mixers, reactors, and vacuum evaporators in food production. It is selected based on the required parameters of the heating system (volume). Our specialists will be happy to assist you in selecting the appropriate pump if you provide the technical specification requirements. This pump is an essential additional component for the flow-through water heater┬Āup to 110┬░C.

- It can be used to circulate water at temperatures up to 110┬░ C

- High efficiency with low power consumption

- Also suitable for central heating systems, heated floors and even for solar systems

- Small connections allow the use of flexible pipes with a smaller diameter

- Type of the equipment: Optional equipment

Various installation types are possible: in-line, directly into the product tank or via a bypass connector.

- Type of the equipment: Optional equipment

A set of additional paddles for transporting and unloading the product from the working area of ŌĆŗŌĆŗthe universal 400/1100/12 fryer.

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts

Additional option to VMG laboratory vacuum homogenizer 20/50.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Within seconds, the device measures the refractive index of the sample and converts it to % of solids using the concentration unit.

The refractometer is ready for use after a simple user calibration with deionized or distilled water.

The set consists of 20 shelves from AISI304 stainless steel.┬ĀAdditional option for MAK DRYER 7-14.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Supporting structure on wheels with locks (brakes), 2 swivel wheels, 2 swivel wheels with a brake.

- Type of the equipment: Optional equipment

Designed for a load of up to 200 kg!

The 5 kW induction cooker is the best alternative to traditional electric and gas stoves. It reduces energy costs, improves safety, and minimizes air pollution, making it suitable for both stationary kitchens and mobile catering setups. Its compact design also makes it a practical choice for small kitchens where space and efficiency matter.

- 10-step power (500ŌĆō5000 W) or 10-step temperature (60ŌĆō280 ┬░C) control

- Connection - 230 Volt

- Compact dimensions: 410x500x200 mm

- Temperature range from 60 to 280 degrees

- Heating power, kW: 5

- Voltage: 220-230V

The IBC container insulation cover is designed for use in ice water stations with IBC containers to maintain the cold coolant at a set temperature.

- Allows you to reduce energy costs of the refrigeration machine - chiller

- Protects from short-term fluctuations in ambient temperature, reflects sunlight (up to 97%)

- The cover is easy to install, with valve holes are installed with hook-and-loop fasteners (Velcro)

- Type of the equipment: Optional equipment

Designed for the demanding requirements of the beer and beverage processing industry, this pressure suction food hose offers exceptional safety, durability, and compliance with international food standards. It is ideal for the transportation of high-quality raw, pasteurized, and organic beer, as well as a variety of other beverages, including wine, soft drinks, and alcoholic drinks.

- Type of the equipment: Optional equipment

Thermal insulation of the drying cabinet body to reduce heat loss during product drying. Additional option for the MAK DRYER 7-14.

- Type of the equipment: Optional equipment

The oil-free four-cylinder piston compressor is the ideal solution for those who value both performance and silence.

- Equipped with two twin-piston units with separate engines

- Four air filters

- Mechanical pressure switch

- Quiet operation (at least 25% quieter than traditional compressors)

- Carrying handle and mobile wheel support

- Principle of operation: Continuous mode

- Total power, kW: 1,5

- Voltage: 220-230V

Analogue refractometers offer an efficient, accurate, and easy-to-use solution for measuring Brix levels and ensuring product quality in the food industry.

- Type of the equipment: Optional equipment

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

Rechargeable and portable, ideal for measuring sugar content in fruit juices and beverages, ergonomic design.