Vacuum paddle meat mixer

Vacuum paddle mixers are designed for fast and precise mixing meat-mass in a vacuum. Used in meat production in meat processing factories.┬Ā

Vacuum Paddle Meat Mixers are designed for fast and precise mixing meat-mass in vacuum.

Used in meat production in meat processing factories. This machines use a dual system of mixing paddles which allows for precise and steady mixing of all stuffing ingredients.

VACUUM MEAT MIXER - SUITABLE PRODUCTS:

- Meat mixed with spices

- Meat hash

- Minced meat

MAIN CONSTRUCTION FEATURES OF A VACUUM PADDLE MIXER:

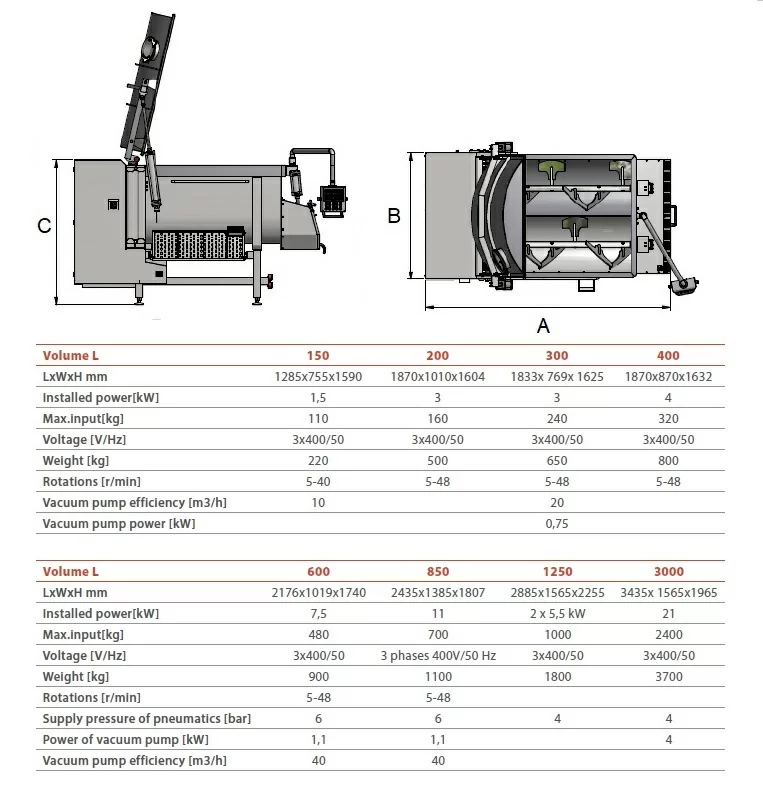

One or dual shaft system with mixing paddles, smooth, variable speed of mixing by using inverter; clockwise and anticlockwise rotations, 100% of stainless steel, manual tilt of mixer during unloading for 150L vacuum mixer, pneumatic loading and unloading system for the rest of the vacuum mixers; vacuum system (Busch pump); in 200L mixer, there are solid, full metal mixing shafts; meat-mass unloading adapted to standard 200 liter stuffing trolley for the mixers with capacity 300, 400, 600, 850, 1250 and 3000L. 600L, 850L and 3000L vacuum mixer is adapted for the loading pillar (optional); 1250L has two speed motors and right, left rotation. 3000L vacuum mixer has two speeds of mixing; water dosing system; load cells system, loading and emptying valve opened and closed pneumatically, loading pillar (optional); manual or automatical control of mixing. All components, such as engine and vacuum system are located in the cover, and access to them is possible only when cover is removed. Electrical installation is located in box on the side of the machine

HOW THE VACUUM MIXER WORKS:

Mixers have a variable direction of rotation of paddles and variable speed of mixing by using inverter. Whole machine is made of stainless steel, it allows to keep it clean. The mixing process can be carried out in a vacuum at a pressure of 0.07 mpa or at atmospheric pressure. Mixers have a variable direction of rotation of paddles and variable speed of mixing. Machine is integrated with loading pillar which can load standard 200 L trolley for meat-mass.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 3000

You might also like

Hydraulic piston fillers for the food processing industry, filling machines for meat and sausages, ideal equipment for meat industry producers and butchers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 20l/ 30l/ 50l

Heating boilers are designed to cook sausages, hams and o’¼Ćal. Technology for superior performance and hygiene.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.┬Ā

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

Paddle Mixer type is designed for fast and precise mixing for meat-mass production in meat processing factories. Can also be used for mixing products such as spices or tea.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 90/ 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 2000 3000

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A rotating drum unit designed for continuous coating and seasoning operations as well as product saturation with spices and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

The Y-shaped food mixer contains a double vessel with a 90┬░ apex angle. This mixing system is designed for mixing, pre-mixing liquid, viscous, dry and bulk components to obtain homogeneous mixtures.

- Special shape designed for fragile products that may break when exposed to centrifugal force

- Effective mixing of products with different components to obtain a homogeneous structure quickly and with minimal energy consumption

- Gentle mixing and tumbling due to complex random trajectories of product movement

- Compact installation

- Easy maintenance and high level of safety - safety bar with a position sensor

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 150l

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

- Engine power, kW: 3

- Principle of operation: Continuous mode

- Voltage: 380-400V

Suitable for mixing a small amount of dough or meat as well as other thick media.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

The AA50 adjustable industrial mixer is designed for efficient, high-performance mixing of liquid, viscous and pasty products, as well as for dispersing dry ingredients (pigments, dyes and other materials) in a liquid medium to obtain highly dispersed suspensions, emulsions and pastes.

- Material: Stainless steel

The 50 liter mixer Mak Mix is a universal mixer for mixing, stirring, kneading various solutions and mixtures. Equipped with an easily removable mixing device and a tilting system of the working bowl.

- Gravity mixing which is 40% more efficient, is possible due to the ability to adjust the tilt angle of the working container

- Simple and convenient design for maintenance - compact installation

- Independent stainless steel supporting structure

- Easily removable lid with a mixing device

- Special small elongated protrusion - spout on the edge of the working container for convenient draining and unloading of the product

- Tilt angle for unloading - 110 degrees

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

An evaporating unit is utilized to remove moisture from sweet substances through heating, transforming them into concentrated syrups or solutions.

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 200 l

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

Atmospheric cutter mixer with capacity of 150l for medium size production of confectionery, chocolate, ice cream, ready meals, cheese, cream smoothie, vegetable puree.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 150l

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Geometric volume: 500 l/ 800 l

Mixers are carefully designed, constructed and tested to handle a variety of industrial applications that require mixing, dispersive mixing, distributive mixing and more.

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 500 l

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600