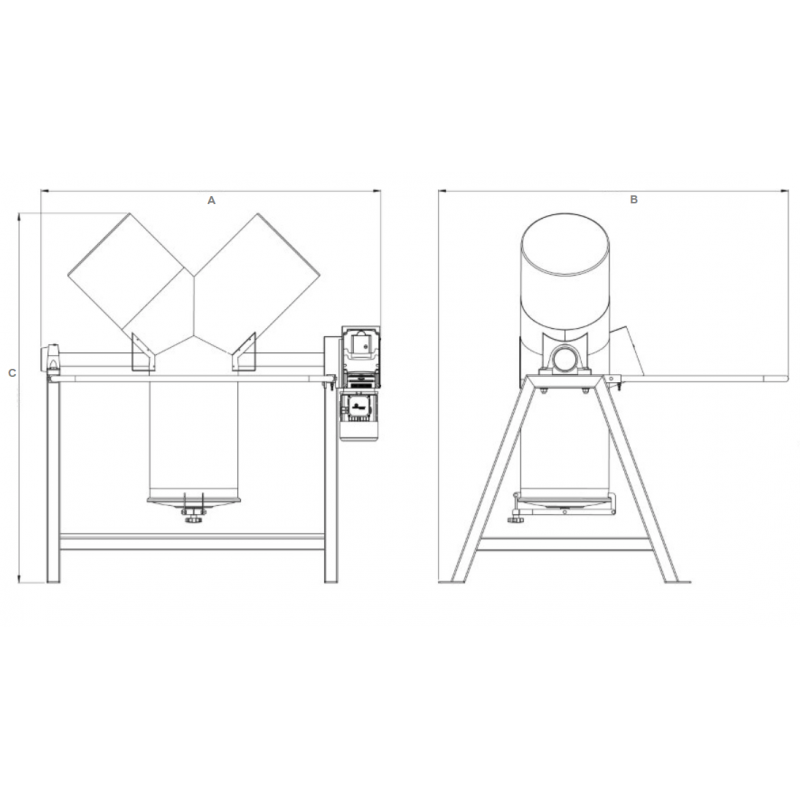

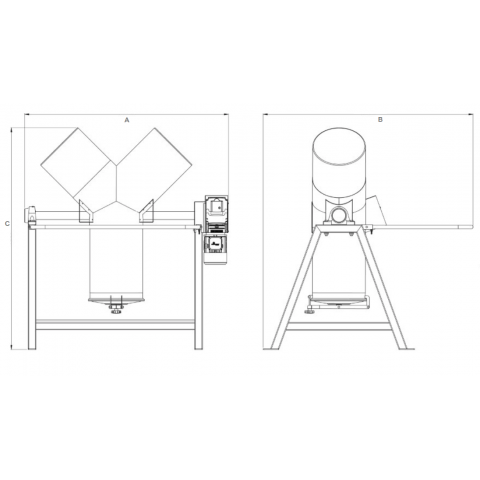

Y mixer 150L

The Y-shaped food mixer contains a double vessel with a 90┬░ apex angle. This mixing system is designed for mixing, pre-mixing liquid, viscous, dry and bulk components to obtain homogeneous mixtures.

- Special shape designed for fragile products that may break when exposed to centrifugal force

- Effective mixing of products with different components to obtain a homogeneous structure quickly and with minimal energy consumption

- Gentle mixing and tumbling due to complex random trajectories of product movement

- Compact installation

- Easy maintenance and high level of safety - safety bar with a position sensor

The drum mixer and the Y-shape mixers are designed for mixing, granulating and emulsifying products such as:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Can be used in the food, chemical, cosmetic, pharmaceutical and construction industries.

Advantages

- High mixing efficiency due to constant separation of components into two streams and reverse mixing.

- High-quality mixing and obtaining a homogeneous mass does not require much time or energy consumption.

- A soft form of mechanical mixing, which is based on the gravitational pouring of the product due to its own gravity while maintaining the structure of the mixed components.

- Suitable for mixing different fractions of bulk products to obtain a homogeneous structure.

- Smooth control of the rotation speed due to a frequency converter, which ensures the selection of the optimal rotation speed for the effective mixing of a particular product.

Basic version

It comprises a special working container in the shape of a heart (with separated double cylinders connected at right angles), suspended on a frame structure with a drive, a safety arc and a control panel in the form of a frequency converter for adjusting the rotation speed. The roll bar must be lowered before starting work. The safety sensor installed on the arc will not allow for the installation to be turned on if the arc is not in a horizontal position.

Options

- A control panel with timers for setting mixing time

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 150l

The laboratory vacuum cutter mixer is designed for uniform grinding, emulsifying and mixing of food, cosmetic and pharmaceutical products, chemical mixtures with the addition of oil, dyes, concentrates or liquid flavors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The new design of the universal cutter with gravity mixing is used for the production of thick and pasty products. The cutter is designed to carry out production processes such as cutting, mixing, crushing and emulsifying of various types of products to a liquid state. Thanks to the built-in duplicator, it can also be used as a device for the production of cream honey or cream honey souffl├®.

- Cutting knives with a powerful 11 kW electric drive

- Frame mixing device with fluoroplastic scrapers

- Hatch opening sensor for safe maintenance

- Plexiglass hatch for visual inspection

- Duplicator for the thermal liquid around the bottom as well as the walls of the installation

- Inclined design for efficient grinding, homogenization and discharge of thick and viscous products

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 12

- Voltage: 380-400V

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

SIPM 10 liter pasta mixer is designed for medium size commercial operations, ideal for medium-size restaurants to produce any kind of pasta such as spaghetti, taglia pasta, cannelloni, macaroni, conchiglie, rigatoni, penne and many others. The price includes a pasta cutter.

- Productivity: 8,4 kg/h

- Material: Stainless steel

- Engine power, kW: 0,75

The appropriate mixing equipment for drum processing depends upon the properties of the products and with the available drum opening.

- Type of the equipment: Individual machine

- Voltage: 230 V/ 380-400V

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

The KWS mixing vessel is engineered for versatile operations, including heating, cooling, and mixing of liquid products, with a maximum heating temperature of 60 ┬░C.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Geometric volume: 100 l

A professional mixer for the production of mayonnaise, sauces, soups and other homogenized products. The price depends on your production capacity, as well as the technological requirements.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

The salt dissolving equipment is designed for preparing high-quality marinades, brines with crystal salt, as well as various syrups with the addition of flavor enhancers and essences in small quantities.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 250l/

An evaporating unit is utilized to remove moisture from sweet substances through heating, transforming them into concentrated syrups or solutions.

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 200 l

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

- Built-in jacket for the bottom and walls of the unit.

- Cutter knives with a powerful electric drive

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Industrial churning machine available in two capacities. Simple production of butter.

- Geometric volume: 30 l/ 70 l

The NDM + drum mixer is designed for thorough mixing while retaining the structure of loose products without dead zones and with relatively low consumption and short mixing time. Made for mixing products such as coffee, tea, nutrients and supplements, baby food and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

Stainlees steel free standing mixer for meat and dough.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1

- Principle of operation: Batch mode

- Volume: 40 60l/ 80l/ 120l

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as a┬Āvacuum evaporator, a┬Āvacuum cooking kettle, and a┬Āunit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar