Cookie making machine JCD

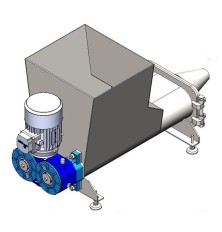

This cookie making machine is designed to produce an unlimited variety of cookies, cakes, and other pastry snacks. We offer five different types of cookie depositing machines, each tailored to various cookie types

The cookie depositor serves as equipment designed for processing various types of pastry dough, such as shortcrust pastry, choux and puff pastry for creating products like sponge cakes, pastry sheets, brownies, ├®clairs, cupcakes, muffins, macarons, choux buns, ladyfingers, biscuits, cookies, and more.

This versatile cookie equipment is suitable for diverse processes, including cream distribution and cake decoration. Utilizing this cookie-making machine for pastry manufacturing in bakeries or pastry factories undoubtedly modernizes operations, enhances effectiveness, and expands the product range.

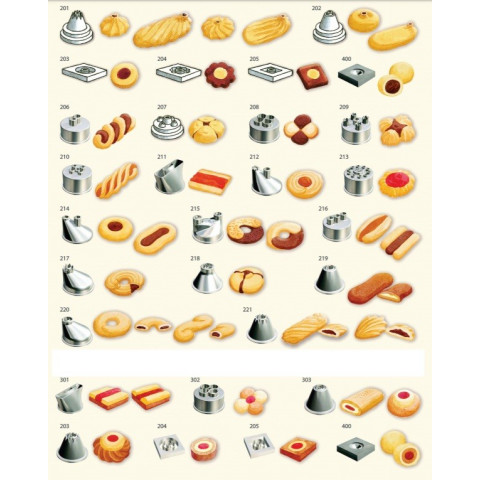

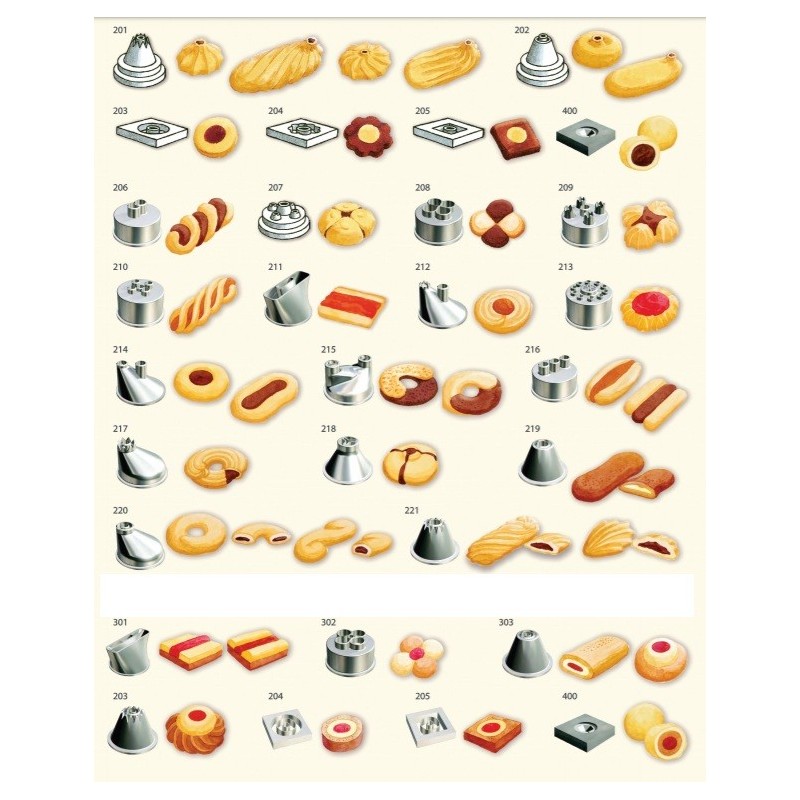

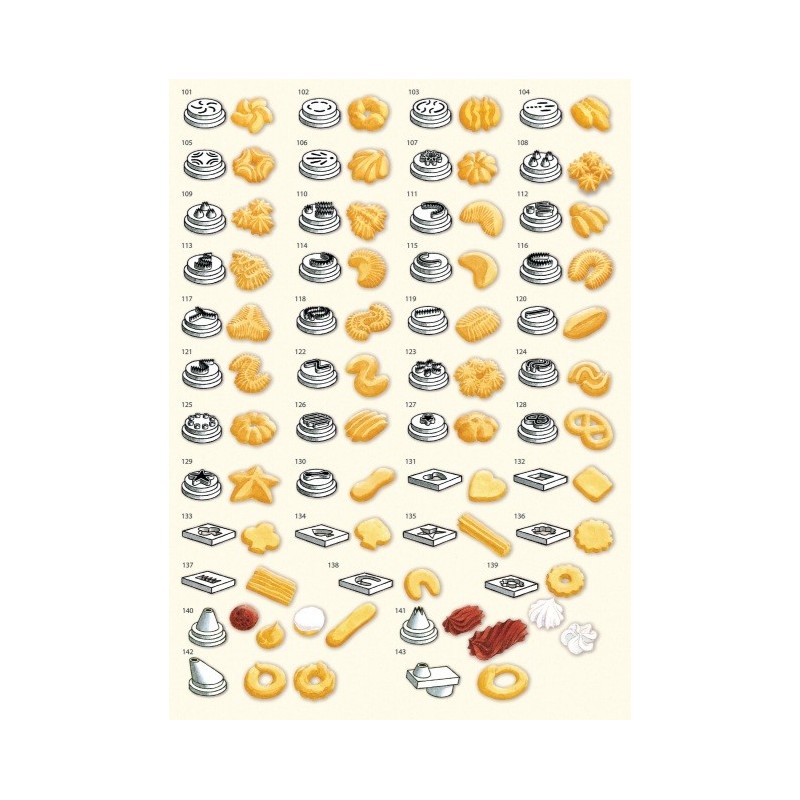

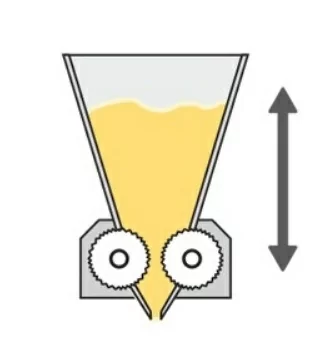

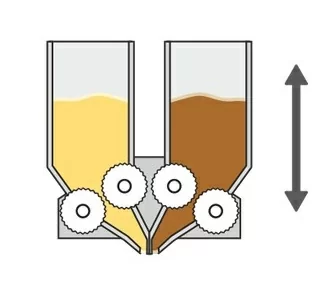

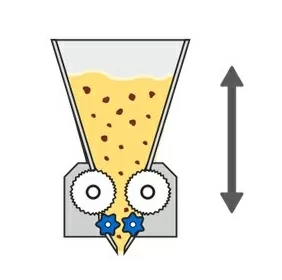

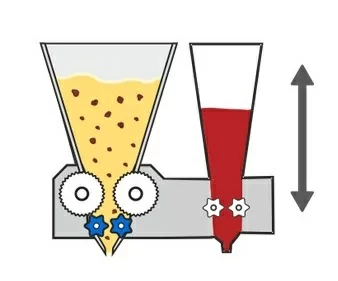

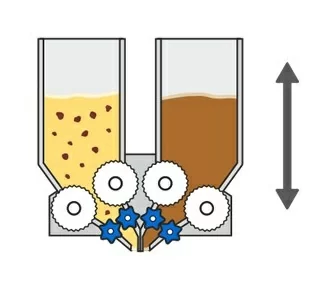

VARIOUS FILLING HEADS

This cookie-making equipment, with its special construction utilizing duo pumps (PLUS versions), a movable filling head, and a fixed-height conveyor, enhances its capabilities. When considering the purchase of this equipment, factors to consider should include the amount of dough, colors, filling requirements, tray capacity, pastry type, and the manufacturing range.

ADVANTAGES:

Maximum efficiency and minimal space requirements. This robust semi-industrial cookie making machine is designed to accommodate primarily medium and large bakeries.

The cookie maker can be used for the production of pastry products from light dough (fruit cakes, cream puffs) or thin dough (sponge cake). If equipped with an additional gear pump, the equipment can handle thick dough with ingredients (e.g., coconut). The pastry machine can be produced in various configurations, processing one type of dough, or two types of dough simultaneously, or even two types of dough plus the filling (trio).

The cake & cookie making machine includes a touchscreen control panel

The touchscreen control panel allows the operator to choose a working program, add or edit the criteria for the form, amount as well as the manufacturing technology. Selecting and amending specific settings is done automatically, along with controlling positions or moving operating features. Accuracy and repeatability are ensured with induction engines and precise control with measuring tools.

The cookie-making machine's manufacturing capabilities are divided into five categories, each configurable in 99 production programs. All equipment options have adjustable modifications on both sides of any edge and any stroke (regulated by precise principles).

The cookie equipment can operate at a speed of up to forty strokes per minute. Assembling the pump pieces, funnel, nozzle turning system, or various types of nozzles is extremely simple and can be done by the operator in a matter of minutes. The installation of the various systems after washing is also done quickly. The equipment can be fitted with a wire cutting system.

Benefits:

- Solid frame construction

- Various regular and unique devices, including the holder for thin dough and a diaphragm-type holder for cookie cutting with concurrent closing

- Easy exchange of the filling heads and other additional options

- Simple cleaning of the components in contact with dough

- Extensive material shaping capabilities and functions using a microprocessor controller with a large memory volume

- Available extra device for decorating cookies by raising and lowering the filling and shaping tool while the conveyor stops.

COOKIE MACHINE JCD ONE┬Ā

| MODEL┬Ā | Trays width cm | Hopper capacity L | Power kW | Power supply | Weight kg | External dimensions LxWxH cm |

| JCD ONE 40 | 40 | 2.1 | 230V, 50Hz | |||

| JCD ONE 45 | 45 | 30 | 2.1 | 230V, 50Hz | 270 | 75 x 105 x 165 |

| JCD ONE 60 | 60 | 40 | 2.1 | 230V, 50Hz | 320 | 75 x 120 x 165 |

COOKIE MAKING MACHINE TWO┬Ā

| MODEL┬Ā | Trays width cm | Hopper capacity L | Power kW | Power supply | Weight kg | External dimensions LxWxH cm |

| JCD TWO 40 | 40 | 2.5 | 230V, 50Hz | 75 x 120 x 165 | ||

| JCD TWO 45 | 45 | 30 + 30 | 2.5 | 230V, 50Hz | 270 | 75 x 120 x 165 |

| JCD TWO 60 | 60 | 40 + 40 | 2.5 | 230V, 50Hz | 320 | 75 x 120 x 165 |

COOKIE DEPOSITOR ONE PLUS┬Ā

| MODEL┬Ā | Trays width cm | Hopper capacity L | Power kW | Power supply | Weight kg | External dimensions LxWxH cm |

| JCD ONE PLUS 40 | 40 | 2.4 | 230V, 50Hz | |||

| JCD ONE PLUS 45 | 45 | 30┬Ā | 2.4 | 230V, 50Hz | 290 | 75 x 105 x 165 |

| JCD ONE PLUS 60 | 60 | 40┬Ā | 2.4 | 230V, 50Hz | 350 | 75 x 120 x 165 |

COOKIE DEPOSITOR COMBI PLUS┬Ā

| MODEL┬Ā | Trays width cm | Hopper capacity L | Power kW | Power supply | Weight kg | External dimensions LxWxH cm |

| JCD COMBI PLUS 40 | 40 | 3.0 | 230V, 50Hz | |||

| JCD COMBI PLUS 45 | 45 | 30 + 15 | 3.0 | 230V, 50Hz | 270 | 75 x 105 x 165 |

| JCD COMBI PLUS 60 | 60 | 40 + 15 | 3.0 | 230V, 50Hz | 320 | 75 x 120 x 165 |

COOKIE MAKING MACHINE TWO PLUS┬Ā

| MODEL┬Ā | Trays width cm | Hopper capacity L | Power kW | Power supply | Weight kg | External dimensions LxWxH cm |

| JCD TWO PLUS 40 | 40 | 230V, 50Hz | ||||

| JCD TWO PLUS 45 | 45 | 30 + 30 | 3.3 | 230V, 50Hz | 370 | 75 x 105 x 165 |

| JCD TWO PLUS 60 | 60 | 40 + 40 | 3.7 | 230V, 50Hz | 420 | 75 x 120 x 165 |

- Engine power, kW: 2,4/ 2,5/ 3,3 3/

- Principle of operation: Continuous mode

- Voltage: 220-230V