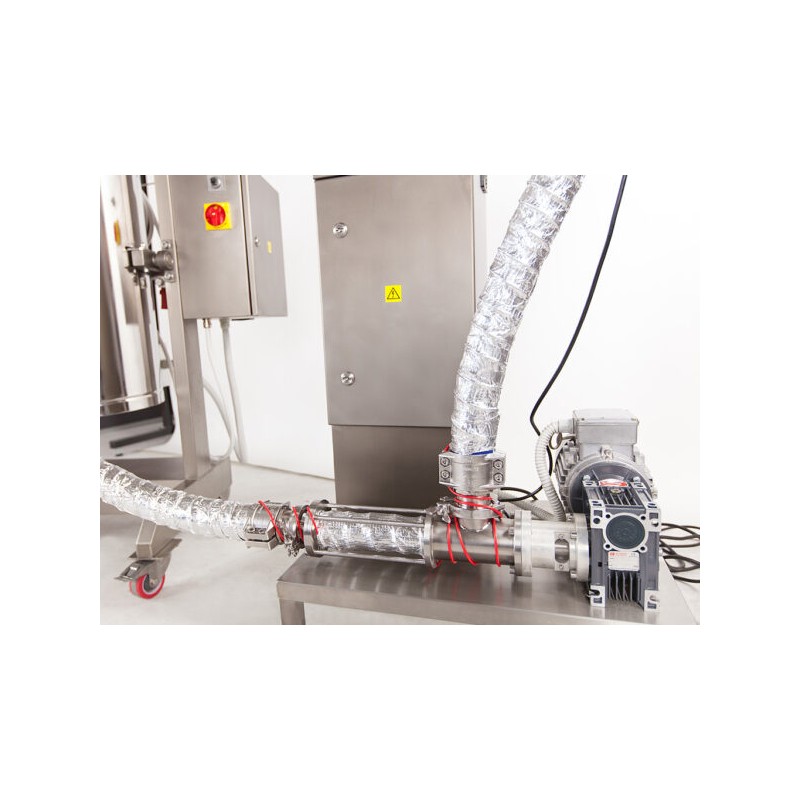

Chocolate melting machine with a heated pump MKCH

Chocolate heating pump is the perfect solution to upgrade your production line. You can easily connect the pump to any device (such as a chocolate enrobing machine).

Chocolate melting and pumping machine is the perfect solution to upgrade your production line.

You can easily connect the pump to any device (such as a chocolate enrobing machine). Thanks to full control over the melting process, the chocolate is not subjected to caramelization or cutting, which guarantees the invariance of taste. The machine is capable of handling even the most difficult chocolate pressing conditions. The whole set is adapted to work cycles of several hours. Mobile machine - on wheels in standard set.

Equipment for heating and mixing chocolate at the same time.

The mixing process is carried out using a special mixer equipped with scrapers that prevent sticking and burning of the product. Scrapers scrape the product from the walls and bottom of the mixer. Heating is carried out by heating the oil between the two walls of the boiler, so that the heating is very balanced and the product (chocolate) does not burn. Heat is introduced very evenly into the product, throughout its entire volume. The MKCH chocolate melting machine is additionally equipped with a third outer layer to limit heat transfer to the environment. MK machines have two working speeds and the ability to heat the mass to the required temperature. Upon request, it is possible to block the maximum temperature level, above which the operator will not install the machine. This is especially important when mixing and heating chocolate or other coatings or masses. Too high a temperature can change the properties of the product (for example, in the case of chocolate, too high temperature can ignite and irreversibly change the taste).

Chocolate melting point:

Depending on the quality of the chocolate, the melting point of the chocolate may vary.

- White chocolate - 40-45¬į–°

- Milk chocolate - 45-50¬įC

- Dessert chocolate - 50-55¬įC

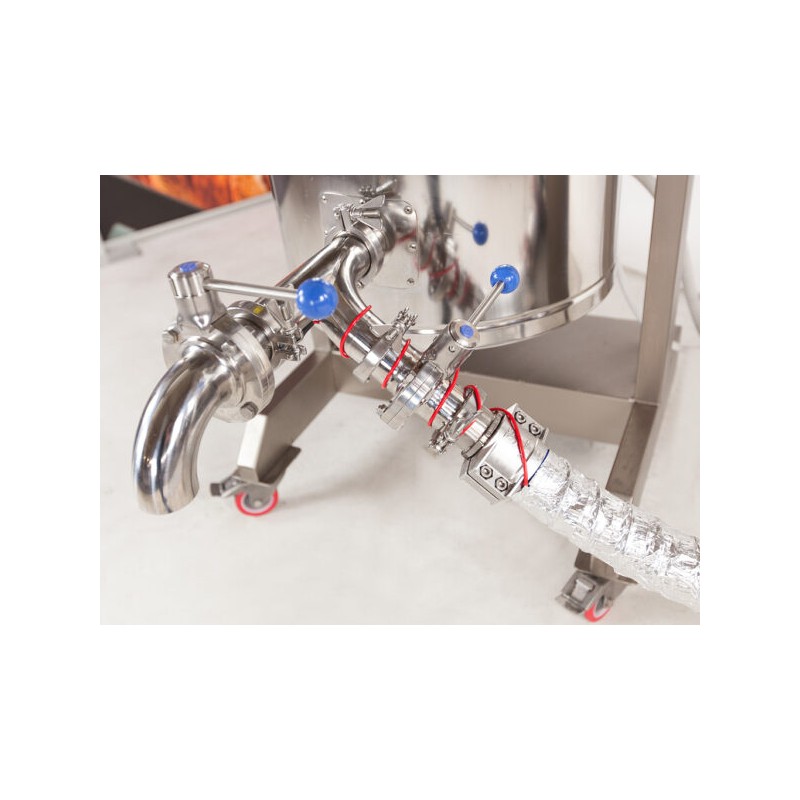

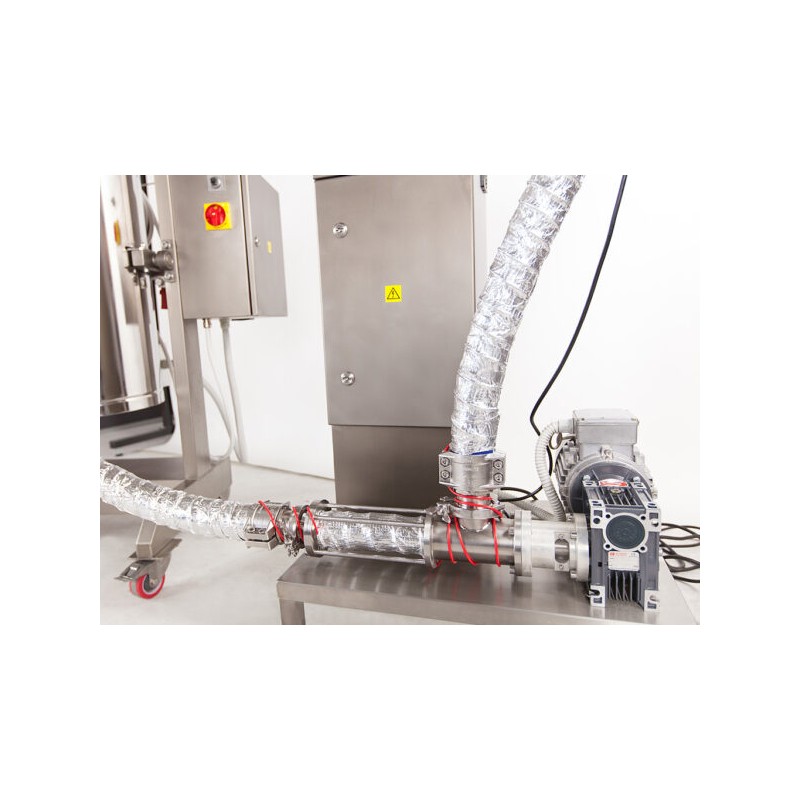

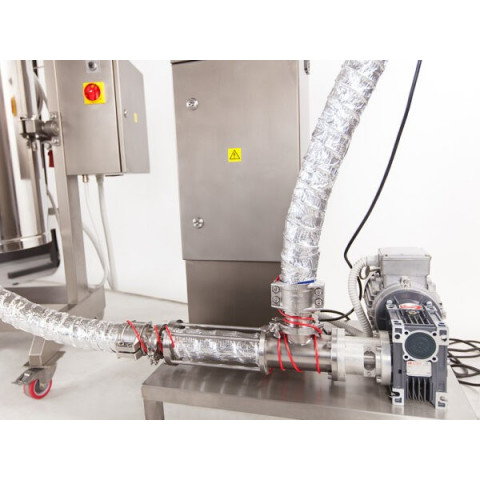

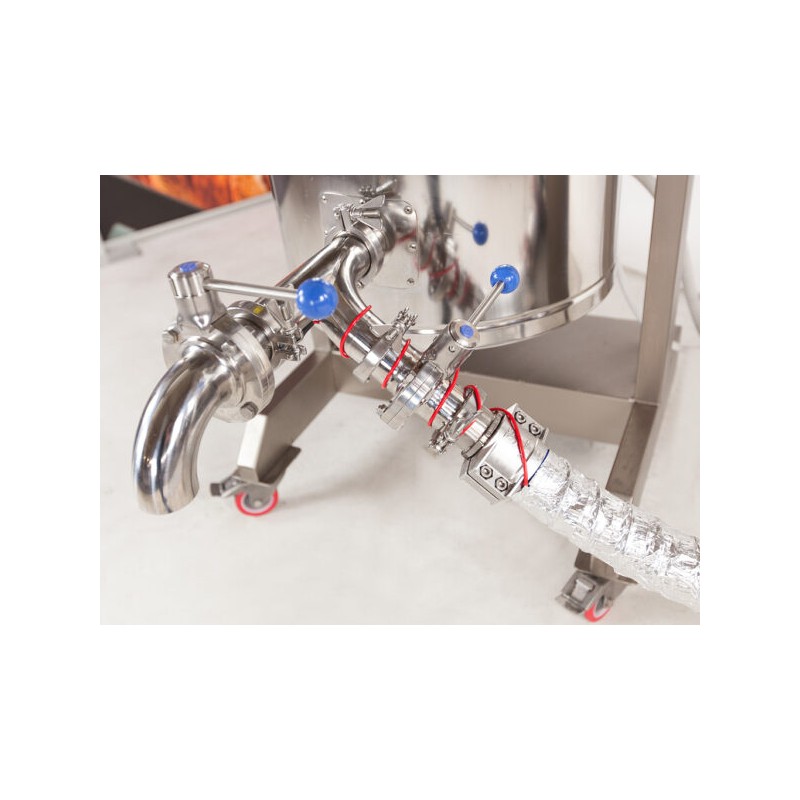

Pump for chocolate, icing, puddings and other masses.

Choosing the right chocolate pump ensures that the pumping process runs smoothly. The chocolate passes smoothly through the pipe and pump (heating jacket on the pipe and pump) and reaches the final receiver in an intact shape and structure.

Additional configuration of chocolate melting machine:

- Variable speed (inverter) - standard on MK-200/300 and 500

- Bowl lid/grid - available for all models

- Special double agitator - available for all models

- LCD - 7' - fully programmable control panel with recipes

- Product temperature laser sensor.

- Principle of operation: Batch mode

- Voltage: 380-400V

You might also like

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 250l/ 300l

The cost is specified for the basic modification without a heating system

Fat block melters are designed for melting frozen, solid blocks of animal or vegetable fat, as well as maintaining them in a molten state at a specified temperature. We produce models with the option to connect steam as a coolant to the melting grid, separate electric heating systems, or configurations with built-in electric heating for supply into the jacket and melting grid.

- Large area of the melting grid where the coolant circulates

- Special shape of the melting grid, cutting blocks during melting

- Greater versatility in terms of the coolant and its source

- Mirror surface of the melting grid, ensuring high hygiene

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l/ 300l/ 500l/ 1000l

The tempering machine ensures a shiny, smooth finish and stable structure for chocolate, significantly reducing the possibility of fat bloom. This equipment is essential in the production of various sweets, confections, chocolate-coated dragees, and other applications requiring chocolate coatings.

- 4-zone tempering system

- Automatic control system

- Temperature measurement in each zone at the inlet and outlet

- High productivity from 150-300 kg/hour

- Heating: Electricity

- Productivity: 150-300 kg/h

- Heating power, kW: 10-18

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

The Atmospheric Evaporating Pan efficiently concentrates liquids by evaporating them on a large surface area, while also being suitable for various cooking methods including braising, cooking, and roasting.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The brewery boiler comprises a two-pot-shaped assembly, in which the integrated frame is a built-in lauter tun, a mash tank, a whirlpool, a laboratory sink and a control panel.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1800l

Vacuum evaporator with remote circulation using a heat exchanger is one of the most efficient evaporation methods. This evaporation system is suitable for boiling and concentrating heat-sensitive products such as milk, cream, etc.

- No mixing device required, the product has forced circulation!

- Modular system: possibility to choose the vacuum generator, power and heat exchanger type

- Inclined design and bottom valve for 100% product discharge without losses and blind spots

- Insulated upper hatch of the unit for heat retention and safety

- Tangential product inlet into the vacuum vessel for guaranteed evaporation in a thin layer

- Material: Stainless steel

- Volume: 50l/ 100l/ 300l

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

A professional cooking boiler with built-in intensive bottom heating and a tilting system for the working container allows you to quickly heat the product to high temperatures (200¬įC). Suitable for blanching, boiling, frying and stewing various products where high-temperatures and efficient processing is required.

- Powerful bottom heating with uniform heat distribution (2600 / 6500 W)

- Professional stainless steel probe in the product with a thermometer for visual control

- Compact standing supporting structure for safe operation

- Three-stage adjustment of the tilt angle of the working container

- The unit is made entirely out of stainless steel

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3,5/ 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

A versatile atmospheric kettle suitable for cooking various products, including jams, syrups, sauces, fruit and vegetable juices, and many others.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 250l/ 300l

Double-jacket stainless steel cooker for marmalade and jam production.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

- Principle of operation: Batch mode

- Volume: 50l/ 80l/ 120l

- Voltage: 380-400V

The cooking boiler is equipped with a jacket for heating as well as a heating system, an electrically driven stirrer (with a geared motor) and Teflon scrapers, which allow for the processing of products with low to medium viscosity. The cooking device is also equipped with a vacuum system.

- Productivity: 100l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

The cream-cooking kettle with manual tilting is designed for controlled heating, concentration, and thermal treatment of cream and cream-based products. Its adjustable temperature control, gentle handling, and uniform heat distribution enable processes such as thickening, reduction, pasteurization, and the preparation of dessert bases.

- 6-stage heating intensity adjustment

- Uniform heat distribution for a consistent product consistency

- Manual tilting system for complete and convenient emptying

- Suitable for cream, dairy desserts, sauces, and similar products

- Smooth stainless steel interior for easy cleaning and maintenance

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia