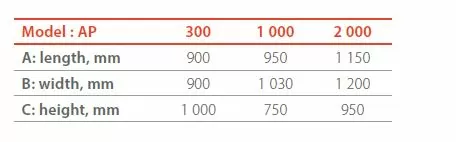

Tensometric honey filling and dosing machine AP

Normit AP tensometric filling machine is a weight-based system for filling honey into barrels.┬Ā

The AP filler is intended for dosing and packing the finished product (e.g. honey) into large industrial containers by weight.┬Ā

There is used a strain gauge weight system where dosing accuracy is about 0.5%.┬Ā

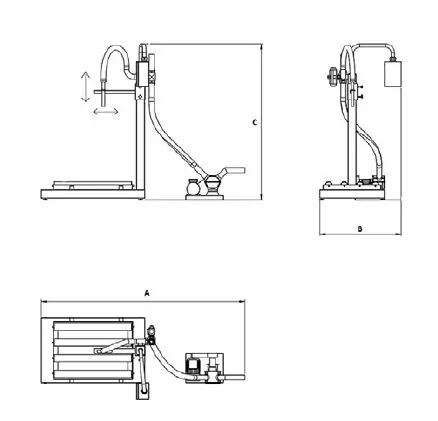

The AP-series fillers are usually installed in a set along with a container for processing honey. The filler consists of a working platform with a tensometric (weight-measuring) system, loading rollers, a dosing system based on an impeller pump, peristaltic pump, or piston pump, a piping and valving, and a control system.

Working principle┬Ā

The operator brings an empty barrel with a forklift, sets it on the rollers for loading, and brings it to the working platform together with the pallet. The strain gauge is located under the working platform. At the operatorŌĆÖs command, the barrel will start to be filled by means of the pump, and as soon as the indicators reach the specified weight, the control system gives the command to turn off the pump.

Packaging honey evenly and keeping it in a liquid state is ensured by a continuously running circulation of honey through the collecting or processing vessel (homogenizer, dryer, etc.) and piping. Supplying honey to the filler begins when a discharge valve on the circulation piping opens.

A system for filtering honey can be installed in the piping if needed.

Advantages:┬Ā

- Durable and reinforced construction.

- Capable of filling different-volume containers with great accuracy.

- Minimal maintenance costs.

- Can be manufactured with different types of pumps at the customerŌĆÖs request.

- System can be worked by a single operator.

- This system for filling honey into bulk packaging can be equipped with conveyors for automatically supplying packaging when in automatic operation.

- Multiple drum filling stations can be installed.

- Material: Stainless steel

- Country of origin: Slovakia

You might also like

This convective honey dryer is used for drying and mixing honey, it is a high-performance solution for thoroughly mixing honey while simultaneously removing excess moisture.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 230 V/ 380-400V

We produce atmospheric honey homogenizers with a batch load ranging from 7500 up to 22 000 kg of honey. The homogenizers HPL are designed for thoroughly mixing, blending, and homogenizing various kinds of honey to improve its qualities.

The price depends on the options you choose.

- Productivity: do 12000 kg

- Material: Stainless steel

- Volume: 8000 l

We offer many different types of pasteurizers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The mixers are made up of a double-walled cylindrical stainless steel vessel with cavity, with drain hole and 50 cm diameter butterfly valve. The cavity is filled with water which is heated by an electric resistance thermostat. The honey is mixed by blades with a marine propeller profile, adjustable in height along an oblique shaft.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55/ 1,1

- Principle of operation: Batch mode

- Volume: 100 kg / 250 kg/ 600 kg/ 1000 kg/ 2000 kg

- Material: Stainless steel

- Engine power, kW: 0,18/

- Operation mode: Automatic

- Country of origin: EU

- Voltage: 220-230V

The piston-operated pneumatic liquid dispenser is a semi-automatic filler used for dispensing various low viscosity liquids ranging from 10 to 100 ml in volume.

- Compact tabletop installation

- Simple control with two operating modes: manual and semi-automatic

- Suitable for liquid products with low viscosity (from water to oil)

- Optional compressed air compressor available

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

We offer different types of sausage filling and stuffing machines. This version is a simple tabletop filling device with hydraulic filling.

- Material: Stainless steel

- Engine power, kW: 0,18/

- Country of origin: EU

- Weight: 46

- Volume: 15 l

- Dimensions, mm: 320 x400x1260

Mechanical vacuum filler, regulated by an electronic system, with a frequency converter.

We offer different hopper capacities.

- Material: Stainless steel

- Operation mode: Automatic

- Country of origin: EU

- Volume: 40/ 90/ 125 / 200l

The manual bottle filler is designed to fill liquids in glass bottles.┬Ā

- Productivity: 650 psc/h

- Material: Stainless steel

- Operation mode: Manual

Hydraulic piston fillers for the food processing industry, filling machines for meat and sausages, ideal equipment for meat industry producers and butchers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 20l/ 30l/ 50l

We sell many different filling machines for different products.

- Material: Stainless steel

- Country of origin: EU

This semi-automatic filling machine is used for filling honey as well as other products. We offer many different kinds of filling machines for different applications.

- Material: Stainless steel

- Operation mode: Semi-automatic

A filler is a device designed for dosing and pumping honey. It guarantees comfortable and professional honey processing.

- Material: Stainless steel

- Engine power, kW: 0,18

- Voltage: 220-230V

The piston filler is designed for dosing different types of liquid products in the food, chemical, pharmaceutical and cosmetic industries.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

Cost-effective system for filling barrels on the basis of a scale for filling the product with a pump.

We offer different types of meat stuffing machine for domestic and commercial use.

- Weight: 10 / 12

- Dimensions, mm: 630 x220x230 / 820x220/230

TEPF is a pneumatic dispenser for dosing several kind of products. The machine allows the filling of food, chemical, cosmetic, or pharmaceutical products into diverse type of bottles and jars.

Price depends on the product used.

- Material: Stainless steel

- Operation mode: Automatic Manual

- Type of the equipment: Individual machine

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

The pneumatic piston filler for pastes and liquids is a semi-automatic dispenser designed for dosing various liquids with a low, medium or high viscosity.

- Tabletop compact model

- Includes a built-in 26 l conical storage tank

- A wide dosing range from 300-2500 ml

- Can also be used for products with a high degree of viscosity

- High dosing speed

- Possibility of working in manual or automatic mode

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 300-2500 ml

- Voltage: 220-230V

Semi automatic packaging machine for filling and capping jars.

- Material: Stainless steel