Fat melter for butter / margarine MixMelter

Intense fat melting machines MixMelters are designed for melting frozen, solid blocks of animal and vegetable fat such as butter and margarine as well as to maintain them in a melted state at a given temperature. Working volume up to, l: 200 l.

Intense fat melter with an integrated mixing device is a batch-type device, intended for melting solid or frozen blocks of fat, vegetable oils and animal fats, frozen juices, chocolates, glazes and alike, keeping the melted products in a liquid state.

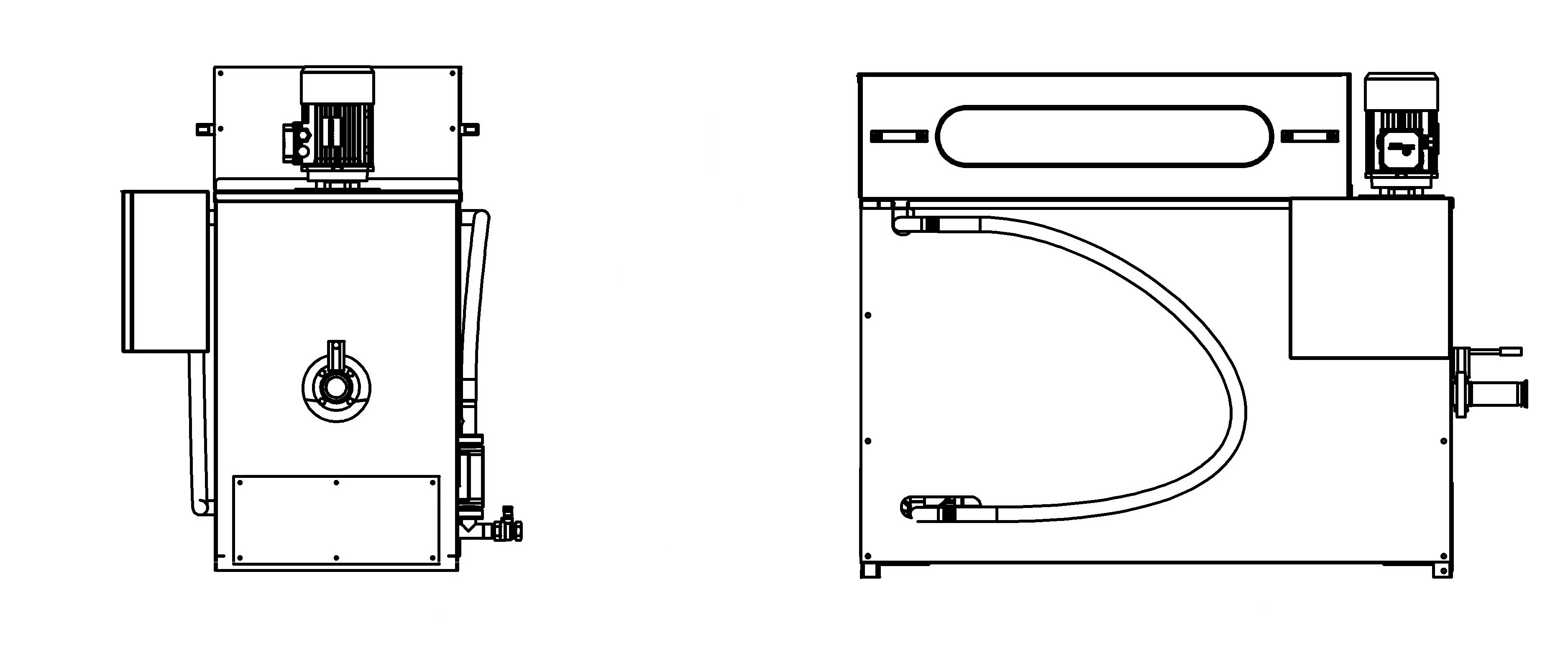

The distinctive feature of the equipment is the special tube melting grid, installed in the upper part of the melting machine.

This melting equipment is often used in food, cosmetic, pharmaceutical, chemical industries for processing butter or margarine, ointments, lubricants etc.

DESIGN

The fat melter consists of working tank equipped with a removable lid, melting tube grid, mixing device and control unit. Heating is performed with the help of an external heat source. An electric flow heater with capacities of 12-24-48 kW can be offered separately.

The exact capacity of the melter depends on the type of the product, the temperature of the infeed blocks, ambient temperature and temperature of the melting grid. Melting capacity is increased with a closed lid.

Advanced design ensures maximum intensity of melting with minimal energy loss. Melting of fat blocks is carried out with the help of a specially shaped heat exchanger and intense circulation of the heat-transfer agent is ensured by convective heat transfer. from AISI304 stainless steel for the food industry.┬Ā

ADVANTAGES

- Maximum intensity of heating thanks to a very short energy transfer distance between heating elements and the heat-transfer agent

- Mixing device

- Increased heat exchange area compared to models with melting grid

- Simple design: minimal number of junctions, ease of operation, durability

- Manufactured from AISI304 stainless steel for the food┬Āindustry.

OPTIONS

- second heat exchanger for doubled intensification of the melting┬Āprocess

- melted fat transportation system

- melted fat tempering system

- magnetic separator

- weight-based dosing system

- AISI316L for product contact parts

- control and automation┬Āsystems: level indicators, portioned discharge of melted fat, etc.

- Material: Stainless steel

- Heating power, kW: 12/ 24/ 48

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 200 l