Suitable for homogenization (grinding, mixing, emulsification, uniform distribution of components throughout the volume) of fluid as well as viscous and thick emulsions, with the purpose of obtaining highly dispersed and resistant multicomponent mixtures from hard to mix liquids or dry ingredients.

The process of mixing is performed with these equipment:

- vertical mixer/ horizontal

- storage tanks

- Vertical mixer

Spiral sscending movement around the circuit generates a continuous flow of the mixture from the center downwards. The industrial mixer therefore provides unparalleled quality two-way mixing screw at the bottom ensures full product outlet.

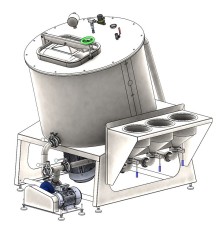

Horizotal mixer with two shafts-high quality and efficient device which is suitable for continuous mixing includes measurement and control systems suitable for continuous operation, the movement of two counterrotating agitator shaft provides intense vertical and horizontal movement of the mix. The design is low maintenance, includes integrated CIP station - tube cleaning further platform for mixer platform for dosing (allows an accurate dosing).

The mixer is a closed cylindrical container. All parts in contact with the product are made of stainless steel. Procedure: The colloidal and rigid parts of the mixture enter into the holes at the top of the device. Subsequently, the product is in a continuous motion thoroughly mixed. The stirrer is positioned about 9 mm and above the bottom of the tank at a distance of 5 mm.

The device allows you to avoid clumping, which often occurs when mixed. This enables you to produce better products, since homogeneity is preserved.

The device can be used for mixing mutually insoluble substances, and also mixtures of solid powders and mixtures of mutually soluble components.

Areas of use:

- Food industry

- Cosmetic industry

- Pharmaceutical industry

- Chemical industry

- Construction/building industry

Benefits:

- The mixer is equipped with a ring-type CIP cleaning system, therefore cleaning of the equipment occurs quickly and efficiently.

- The equipment is made of high quality food grade stainless steel AISI 304, AISI 316

- Low unloading time and optimal unloading of residues

- Hygiene - eliminates the danger that the product will be contaminated with lubricant or the like

- Extremely simple cleaning.

At the customer's request, the following options may be included:

- production in accordance with GMP standards

- equipment lifting stand for easier care of the homogenizer

- complete set with the converter of frequency of rotation for increase in speed of rotation of a rotor

You might also like

The price depends on the selected modifications and specific options

The plow mixer is often used in the food, pharmaceutical, and chemical industries for mixing and saturating powder products with liquid media in order to obtain a high-quality mixture.

- High intensity and quality of mixing, stirring

- Short mixing time and a high productivity

- Guaranteed repeatability and reproducibility of the product batches

- Gentle handling of the product due to the mixing device's special plows

- A large number of options to choose from to fit a specific product type

- Air Purge Seals

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 700l/ 1200l/ 1800l

- Voltage: 380-400V

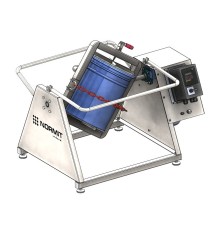

Barrel mixers are used to mix a wide range of loose and granular products in a shipping/barrel container. The available mixer models are suitable for the following volumes:

ConMix 20 - 20-30 liter standard drums with a diameter of 316 mm, adjustable frame structure height

ConMix 75 - 48-65 liter standard barrels with a diameter of 400 mm, adjustable frame structure height

- It is possible to use standard food containers ranging from 20-65 liters

- Easy control via a frequency converter as a stand-alone control panel

- Safe operation thanks to a roll bar with a position sensor

- Engine power, kW: 0,37/ 0,55/ 1,1

The Y-shaped food mixer contains a double vessel with a 90┬░ apex angle. This mixing system is designed for mixing, pre-mixing liquid, viscous, dry and bulk components to obtain homogeneous mixtures.

- Special shape designed for fragile products that may break when exposed to centrifugal force

- Effective mixing of products with different components to obtain a homogeneous structure quickly and with minimal energy consumption

- Gentle mixing and tumbling due to complex random trajectories of product movement

- Compact installation

- Easy maintenance and high level of safety - safety bar with a position sensor

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 150l

The twinscrew mixer with two horizontal shafts is designed for intensive mixing and kneading dough as well as chocolate, pralines and other similar products with medium or high viscosity.

For a price quote, send us an email to sales@foodtechprocess.com

The conical bottom mixer with a 400-liter capacity is designed for efficient mixing and smooth product discharge. Its conical shape directs contents toward the lower outlet, making it ideal for processing thicker or denser materials in an atmospheric-pressure environment.

Homogenizer for the production of whipped cream, ice cream, and much more. It allows you to obtain stable liquid emulsions of food mixtures.

- The homogenizer can be installed directly into the container with the product

- High productivity - in just 8 minutes, it is possible to whip up to 60 liters of milk mixture

- The peripheral speed of the knives is 16 m/s

- Engine power, kW: 0,37/ 2,2

- Voltage: 380-400V

This versatile planetary mixer is a professional kitchen equipment used for mixing, kneading, and blending ingredients in various culinary applications. It features a unique mixing action where the beater rotates on its axis while also revolving around the bowl, ensuring thorough and consistent mixing of ingredients.

For a price quote, send us an email to sales@foodtechprocess.com

A twin-screw mixer with a homogenizer is an ideal solution for the production of creamy cheese, such as feta cheese, including with various flavors and seasonings. Thanks to mechanical homogenization, the cheese acquires a delicate structure without changing the individual taste properties of the product. It is used for plasticizing, creaming and softening butter, margarine and other fats.

- A capacious volumetric mixer with a capacity of 50 l

- Compact tabletop design for convenient operator maintenance

- A powerful independent drive for each screw with a reverser

- Easy maintenance and cleaning of the equipment

- Material: Stainless steel

- Total power, kW: 3,5

- Voltage: 380-400V

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

- Built-in jacket for the bottom and walls of the unit.

- Cutter knives with a powerful electric drive

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Used in chemical, construction, cosmetic or food industries.

For a price quote, send us an email to sales@foodtechprocess.com

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

For more information or a price quote, send us an email at: sales@foodtechprocess.com

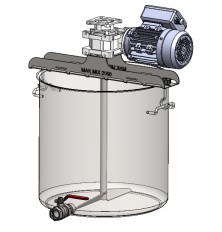

Lid with an automatic stirrer for stainless steel 40 cm pots, suitable for volumes of 50 and 100 liters. An automatic stirrer allows you to mix and stirr various products, including during thermal processing. The type of mixing device can be additionally selected depending on the required process.

- Professional industrial single-phase motor for 220-230 Volts

- The control is located directly on the motor housing or on the drive cable

- Easy and simple installation and fixation of the lid on the pan

- Suitable for standard 40 cm pots with a capacity of 50 or 100 liters

- The lid and stirrer are made entirely out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Voltage: 220-230V

Suitable for mixing a small amount of dough or meat as well as other thick media.

We offer different types of dryers for different products.

For a free consultation, send us an email at┬Āsales@foodtechprocess.com

The mixer is designed for mixing large quantities of dough as well as meat mixtures.┬Ā

The periodic drum coating/seasoning machine is designed to saturate and infuse a diverse range of products with flavorful aromas, vitamins, and various taste additives. It is utilized in the production of snacks, chips, cereals, and nuts, offering a wide array of flavor enhancements.

- Mechanical system for tilting the working bowl with fixation points in intermediate positions

- Special perforated blades for gentle product turning

- Powerful drum rotation drive

- Entirely made out of food grade stainless steel AISI304

- Easy control via an inverter (optional): speed control and reverse

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 0,55

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

A spiral mixer with a fixed bowl and an electronic control panel. Available in various different capacities.

For more information, please contact our sales department at sales@foodtechprocess.com

The NORMIT drum mixers are designed for thorough mixing for products such as combined feed for animals, infant formulas, baby food, food concentrates and additives, sports supplements and nutrients, coffee, tea, pharmaceuticals and chemical products.

Running of various production processes such as cutting, mixing, crushing, refining and emulsifying different types of product in a single unit.

Price depends on the chosen option. Please email sales@foodtechprocess.com

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

For additional information, please contact us at sales@foodtechprocess.com