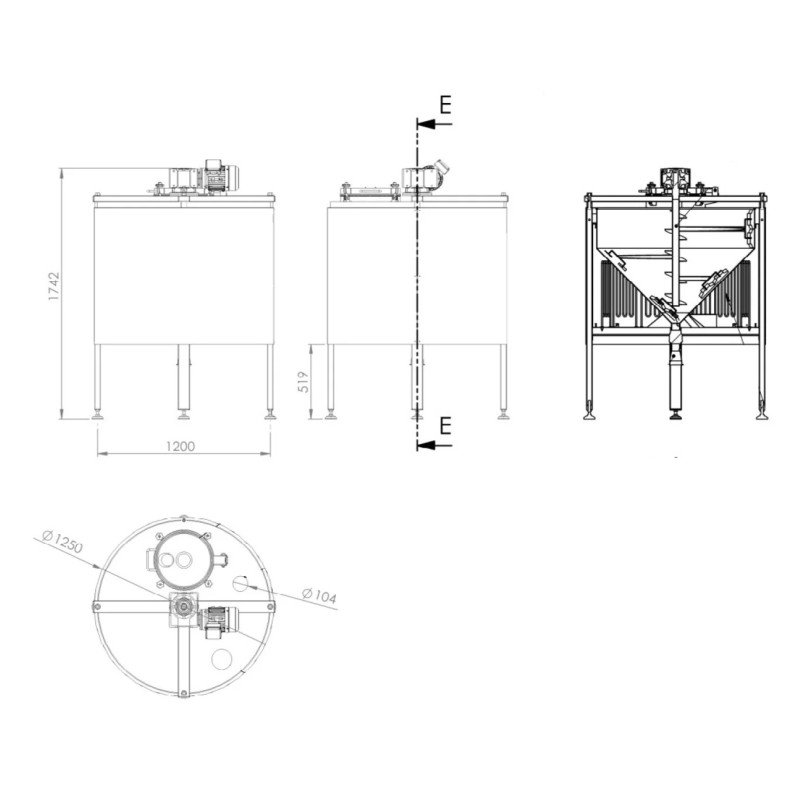

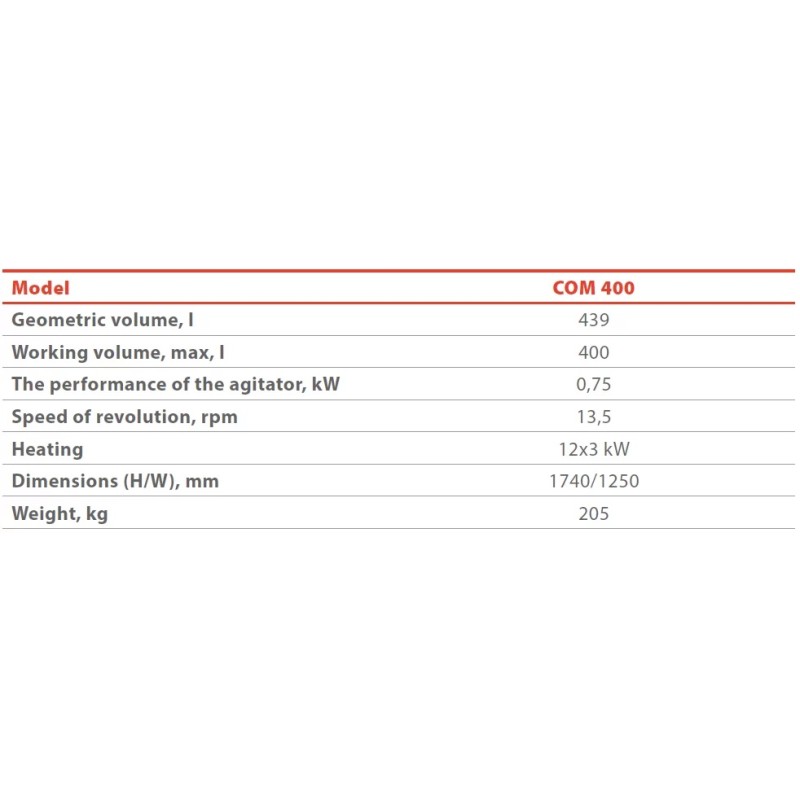

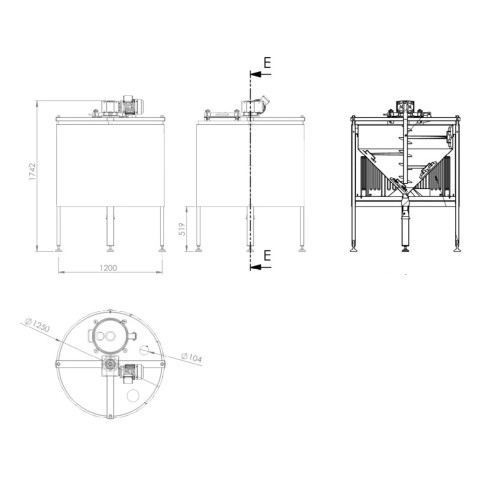

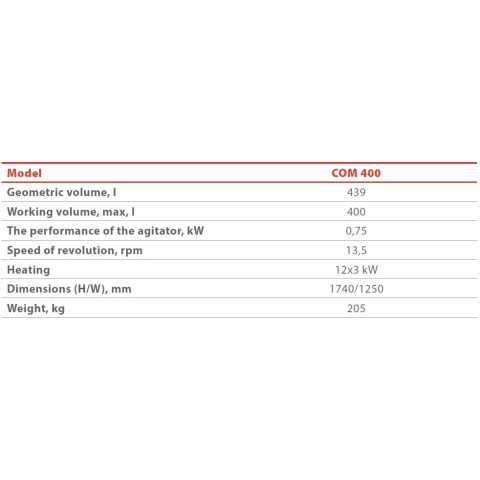

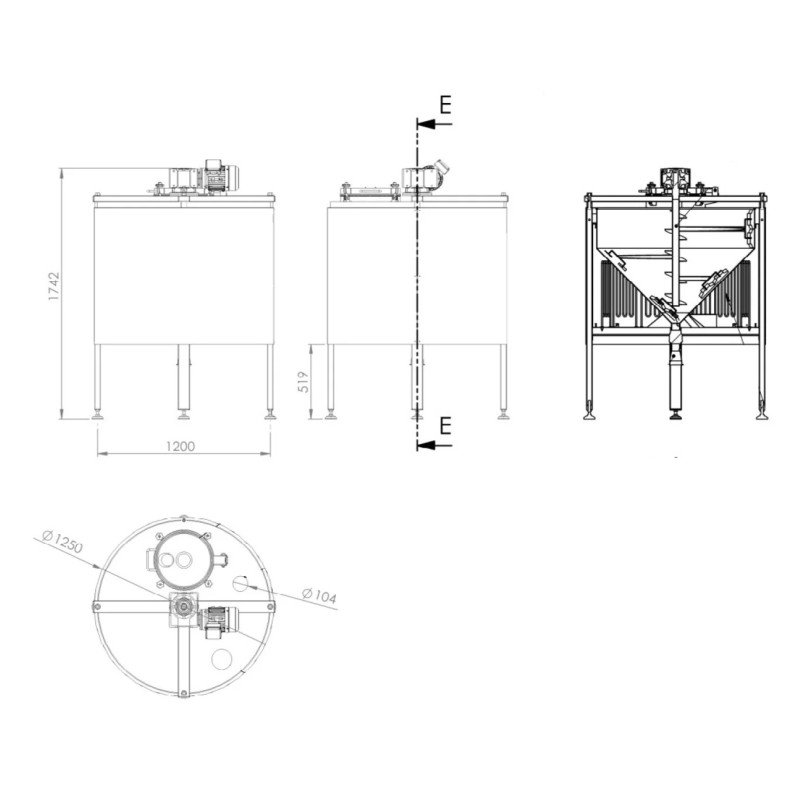

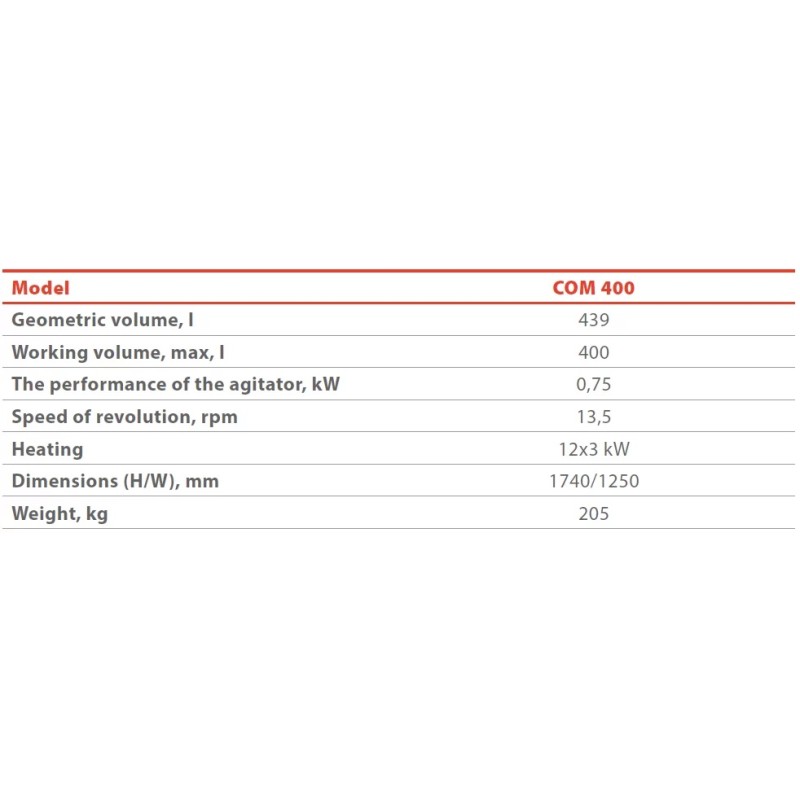

Mixer with a conical bottom COM 400

The conical bottom mixer with a 400-liter capacity is designed for efficient mixing and smooth product discharge. Its conical shape directs contents toward the lower outlet, making it ideal for processing thicker or denser materials in an atmospheric-pressure environment.

A 400l atmospheric mixing vessel - is an ideal solution for small and medium-sized production.

This atmospheric mixer is ideal for small to medium-sized production. Made from high-quality stainless steel AISI 304 (with an option for AISI 316 on request), it features a three-layer insulated structure, a conical bottom, and a specialized screw stirrer equipped with Teflon scrapers. The Teflon scrapers effectively remove product from the tank walls, ensuring uniform processing without product loss, while also making the device easier to clean.

The mixer is heated with specialized electric coils, providing dry air heating of the mixer walls.

The set of┬Āequipment includes:

- Mixer tank

- Mixing device with an industrial three-phase motor

- Teflon scrapers

- Temperature sensor in the product

Control options are selected individually based on automation requirements.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 400l

- Voltage: 380-400V

You might also like

Stainlees steel free standing mixer for meat and dough.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1

- Principle of operation: Batch mode

- Volume: 40 60l/ 80l/ 120l

The KWS mixing vessel is engineered for versatile operations, including heating, cooling, and mixing of liquid products, with a maximum heating temperature of 60 ┬░C.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Geometric volume: 100 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

A spiral mixer with a fixed bowl and an electronic control panel. Available in various different capacities.

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 120 l/ 160 l/ 200l/ 250 l

- Voltage: 380-400V

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

The AA50 adjustable industrial mixer is designed for efficient, high-performance mixing of liquid, viscous and pasty products, as well as for dispersing dry ingredients (pigments, dyes and other materials) in a liquid medium to obtain highly dispersed suspensions, emulsions and pastes.

- Material: Stainless steel

The coating machine is designed for uniform application, impregnation of oil and fat mixture, dyes and flavors, enzymes, vitamins and other additives, various products with a high level of hygiene.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

SIPM 10 liter pasta mixer is designed for medium size commercial operations, ideal for medium-size restaurants to produce any kind of pasta such as spaghetti, taglia pasta, cannelloni, macaroni, conchiglie, rigatoni, penne and many others. The price includes a pasta cutter.

- Productivity: 8,4 kg/h

- Material: Stainless steel

- Engine power, kW: 0,75

The mixers are made up of a double-walled cylindrical stainless steel vessel with cavity, with drain hole and 50 cm diameter butterfly valve. The cavity is filled with water which is heated by an electric resistance thermostat. The honey is mixed by blades with a marine propeller profile, adjustable in height along an oblique shaft.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55/ 1,1

- Principle of operation: Batch mode

- Volume: 100 kg / 250 kg/ 600 kg/ 1000 kg/ 2000 kg

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

The salt dissolving equipment is designed for preparing high-quality marinades, brines with crystal salt, as well as various syrups with the addition of flavor enhancers and essences in small quantities.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 250l/

This 800-liter capacity dissolver with a circulation pump is designed for preparing liquid solutions by dissolving substances directly in water or other working fluids. It is used in the food and beverage industries for ensuring uniform dissolution through hydrodynamic mixing in a forced recirculation loop.

Recirculation with a food-grade pump ensures rapid and uniform dissolution without sedimentation or the formation of stagnant zones. The working tank is mounted on a mobile platform with wheels, allowing for easy and quick movement between production areas.

- Fast and uniform dissolution without sediment thanks to hydrodynamic mixing

- Forced recirculation loop with product pump/inline homogenizer (optional)

- Mobile stainless steel platform on wheels

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Geometric volume: 800 l