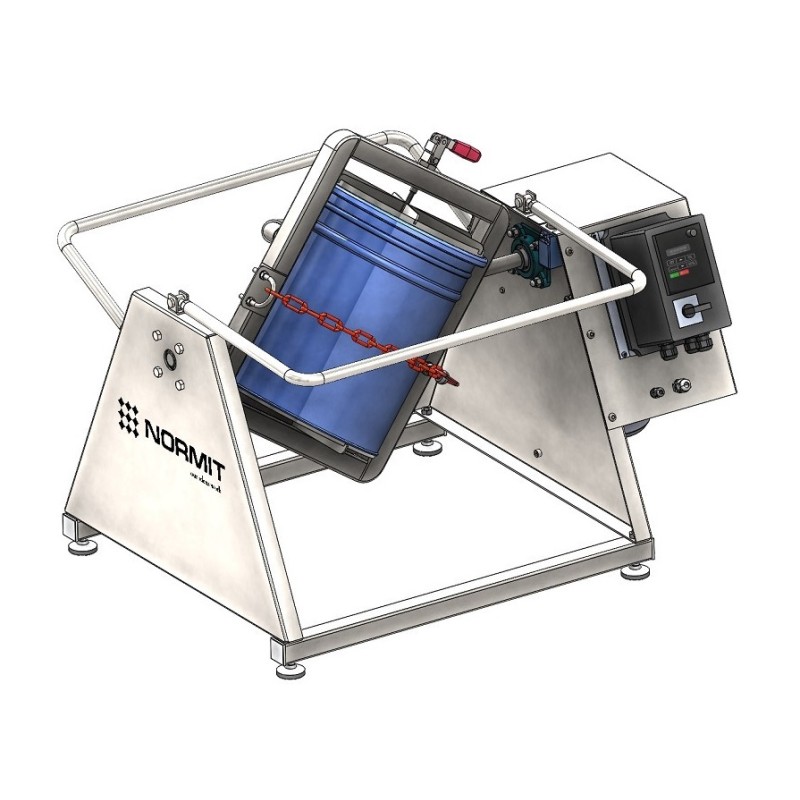

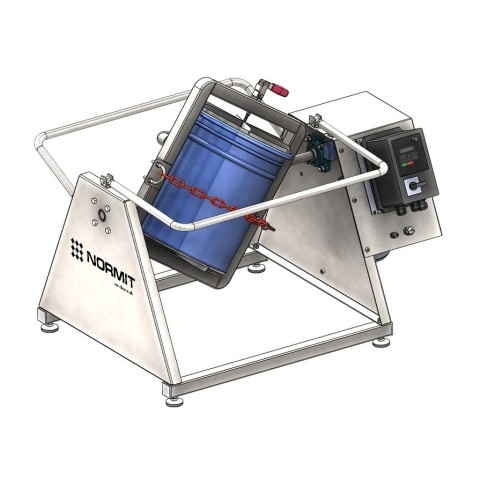

Barrel Hoop Mixer ConMix

Barrel mixers are used to mix a wide range of loose and granular products in a shipping/barrel container. The available mixer models are suitable for the following volumes:

ConMix 20 - 20-30 liter standard drums with a diameter of 316 mm, adjustable frame structure height

ConMix 75 - 48-65 liter standard barrels with a diameter of 400 mm, adjustable frame structure height

- It is possible to use standard food containers ranging from 20-65 liters

- Easy control via a frequency converter as a stand-alone control panel

- Safe operation thanks to a roll bar with a position sensor

The ConMix barrel mixer is a batch-type device for mixing bulk products using the gravitational circulation method, similar to a ¬ędrunk barrel¬Ľ.

Suitable for application in the food, cosmetics, pharmaceutical, chemical and other industries. Designed for mixing a wide range of bulk products in transport containers (for the ConMix20 and ConMix75 models), the equipment corresponds to the highest level of hygiene, since there is no leakage of material from the transport container during product processing. Another big advantage of this type of mixing is that it reduces the time required to mix each batch of product, since there is no need to load and unload the product into the container, just replace it with a new one.

Advantages

- The device ensures a high degree of homogeneity of the final mixture due to the intensive multidirectional movement of the container. The absence of moving parts allows you to efficiently mix bulk or fragile products without the risk of damage. Mixing occurs with the help of gravity.

- Maximum efficiency: the mixer is always only used for mixing, the loading and unloading process occurs separately.

- The ConMix series mixers can also be used to dissolve solid ingredients in liquid product mixtures.

- Versatile use - quickly move on to mixing another product without having to clean the mixing chamber.

- Designed to meet the highest hygienic standards, without the risk of contamination or the need to load and unload the product.

- High performance.

Basic version

The mixer - a ‚Äúdrunk barrel‚ÄĚ type mixer consists of a supporting structure with a drive (geared motor), a protective safety bar and a control panel.

Principle of operation

Before starting (turning the equipment on), the containers must be closed and secured, and the safety bar must be lowered. If the safety arc is raised while the equipment is operating, the unit will turn off automatically. In the barrel fixed in a frame holder inclined relative to the horizontal axis, the product particles tumble under the influence of friction and gravity, colliding with each other. Mixing occurs as a result of slight differences in particle speeds. The products are mixed thoroughly and without taking damage. The mixing time depends on the product as well as the production technology.

The model line

| Model                    | Volumes, l              | Drive power, kW           | Dimensions, mm                 |

| –°onMix20 | 20-30 | 0,37 | 1020/805/826 |

| ConMix75 | 48-65 | 0,55 | 1313/1012/1250 |

| ConMixStatic 100 | 100 | 1,1 | 1404/1324/1313 |

Options

- For the ConMixStatic version, additional systems can be installed - high-speed accelerators that provide controlled granulation and dosing of liquid components in specified quantities.

- ConMix mixers can be customized for any type of container at the customer's request. If needed, the mixer can be made with a fixed (static) container.

Watch a video on our YouTube channel showcasing how our ConMix works.

- Engine power, kW: 0,37/ 0,55/ 1,1

- Volume: 20l/ 75/ 100l

Shaker mixer SMU6 is designed for mixing the contents of packaged products that are in foil or other protective packaging. The device is used in the food, pharmaceutical, chemical, construction and cosmetic industries, where it is necessary to thoroughly mix the contents without damaging the packaging.

- No need to remove the product from the packaging - mixing takes place in the original packaging

- Hygienic and safe mixing without contamination

- Robust and durable construction made of stainless steel AISI 304

- Material: Stainless steel

- Country of origin: Slovakia

Vacuum mixer processing plant for viscous products is an ideal solution for the production of pilot batches and the industrial manufacturing of a wide range of products from small to medium capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

The 50 liter mixer Mak Mix is a universal mixer for mixing, stirring, kneading various solutions and mixtures. Equipped with an easily removable mixing device and a tilting system of the working bowl.

- Gravity mixing which is 40% more efficient, is possible due to the ability to adjust the tilt angle of the working container

- Simple and convenient design for maintenance - compact installation

- Independent stainless steel supporting structure

- Easily removable lid with a mixing device

- Special small elongated protrusion - spout on the edge of the working container for convenient draining and unloading of the product

- Tilt angle for unloading - 110 degrees

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

The Y-shaped food mixer contains a double vessel with a 90¬į apex angle. This mixing system is designed for mixing, pre-mixing liquid, viscous, dry and bulk components to obtain homogeneous mixtures.

- Special shape designed for fragile products that may break when exposed to centrifugal force

- Effective mixing of products with different components to obtain a homogeneous structure quickly and with minimal energy consumption

- Gentle mixing and tumbling due to complex random trajectories of product movement

- Compact installation

- Easy maintenance and high level of safety - safety bar with a position sensor

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 150l

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

A honey homogenizer is a batch-type device designed to improve the product's structure and organoleptic properties. It ensures a uniform consistency and stable texture of honey.

Homogenization is a processing technology that makes honey flowable and uniform, as well as inhibits crystal growth, thus meeting the needs of producers and consumers. The design, size, and angle of the rotary auger achieve a high level of homogenization, which also reduces raw material processing time.

- High level of homogenization, aimed at increasing stability and improving the honey's structure without altering the product's flavor.

- No dead spots or corners due to the inclined bottom of both the working tank and the auger mixer.

- The working tank is equipped with a jacket and a built-in water heating system.

- Large-diameter outlet valve installed at the lowest hydraulic point.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 4/ 7

- Loading, kg: 500/ 1100

This mixing machine is intended for mixing sauerkraut with carrots, beets, salt, spices, also for salad, kimchi mixing etc.

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l/ 600l/

This 800-liter capacity dissolver with a circulation pump is designed for preparing liquid solutions by dissolving substances directly in water or other working fluids. It is used in the food and beverage industries for ensuring uniform dissolution through hydrodynamic mixing in a forced recirculation loop.

Recirculation with a food-grade pump ensures rapid and uniform dissolution without sedimentation or the formation of stagnant zones. The working tank is mounted on a mobile platform with wheels, allowing for easy and quick movement between production areas.

- Fast and uniform dissolution without sediment thanks to hydrodynamic mixing

- Forced recirculation loop with product pump/inline homogenizer (optional)

- Mobile stainless steel platform on wheels

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Geometric volume: 800 l

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

Butter churner with a volume of 50 L and a usable volume of 25 L for the traditional production of butter from cream.

- Material: Stainless steel

- Engine power, kW: 0,55

- Geometric volume: 50 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Atmospheric cutter mixer with capacity of 150l for medium size production of confectionery, chocolate, ice cream, ready meals, cheese, cream smoothie, vegetable puree.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 150l

The dough mixer is a batch type mixing equipment, working in the opposite direction, to produce a wide range of dispersions and emulsions of varying viscosity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar