Tabletop mixer is designed for mixing and kneading dough or meat.

The main feature of the mixer are:

- The mixer is made entirely out of stainless steel.

- Easy to clean and maintain.

- The container can be removed for easier cleaning.

- Easy to use.

- Suitable for mixing meat and dough as well as other media.

- The capacity of the mixer is 2 to 10 kg of meat or 2 to 6 kg of flour.

- The container can be removed for easier cleaning.

- Connection power: 230V or 400V

|

Type |

Quantity of meat |

Quantity of flour |

The size of the container |

Size, mm |

Weight approx. |

Motor power |

Voltage |

|

TIP 10 |

10 kg |

2-6 kg |

10 L |

320x320x380 |

30 kg |

0,55 |

220/380 |

|

TIP 20 |

25 kg |

3-12 kg |

20 L |

500x500x350 |

35 kg |

0,55 |

220/380 |

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

You might also like

The mixer is designed for mixing large quantities of dough as well as meat mixtures.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 80l/ 140l

- Voltage: 380-400V

Stainlees steel free standing mixer for meat and dough.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1

- Principle of operation: Batch mode

- Volume: 40 60l/ 80l/ 120l

Grinder is used for grinding both fresh meat and food products, such as cheese, fruits.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

These meat mixers are characterized by their modern design and strong AISI 304 stainless steel construction.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 110 l/ 163 l/ 250l/

The meat flaker is an automatic machine for cutting frozen blocks of meat into slices.

- Productivity: 2500 kg/h

- Material: Stainless steel

- Engine power, kW: 9,2

- Principle of operation: Continuous mode

The Z-Sigma Arm paddle mixer is designed for intensive mixing, stirring, kneading and plasticizing products with high and very high viscosity, such as chewing gum base, stiff dough with low water content, toffee mass, soap base, adhesives.

- Double Z-shaped blade

- Very high shear force

- Minimum gap between z blades and the working container

- Independent electric drive for each blade

- Electric tilting for automatic unloading up to 180 degrees

- The mixer is made entirely out of food grade stainless steel AISI304

- Possibility to choose the side of tilting and unloading

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 70l/ 140/ 300l/ 460/ 700l/

- Voltage: 380-400V

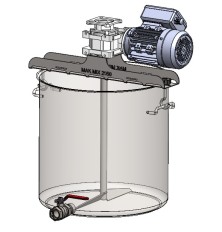

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel

The periodic drum coating/seasoning machine is designed to saturate and infuse a diverse range of products with flavorful aromas, vitamins, and various taste additives. It is utilized in the production of snacks, chips, cereals, and nuts, offering a wide array of flavor enhancements.

- Mechanical system for tilting the working bowl with fixation points in intermediate positions

- Special perforated blades for gentle product turning

- Powerful drum rotation drive

- Entirely made out of food grade stainless steel AISI304

- Easy control via an inverter (optional): speed control and reverse

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 0,55

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

A detachable lid with an automatic food stirrer for stainless steel 40 cm pots, suitable for volumes of 50 and 100 liters. An automatic stirrer allows you to mix and stir various products, including during thermal processing. The type of mixing device can be additionally selected depending on the required process.

- Professional industrial single-phase motor for 220-230 Volts

- The control is located directly on the motor housing or on the drive cable

- Easy and simple installation and fixation of the lid on the pan

- Suitable for standard 40 cm pots with a capacity of 50 or 100 liters

- The lid and stirrer are made entirely out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Voltage: 220-230V

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

- Engine power, kW: 3

- Principle of operation: Continuous mode

- Voltage: 380-400V

The mixers are made up of a double-walled cylindrical stainless steel vessel with cavity, with drain hole and 50 cm diameter butterfly valve. The cavity is filled with water which is heated by an electric resistance thermostat. The honey is mixed by blades with a marine propeller profile, adjustable in height along an oblique shaft.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55/ 1,1

- Principle of operation: Batch mode

- Volume: 100 kg / 250 kg/ 600 kg/ 1000 kg/ 2000 kg

A honey homogenizer is a batch-type device designed to improve the product's structure and organoleptic properties. It ensures a uniform consistency and stable texture of honey.

Homogenization is a processing technology that makes honey flowable and uniform, as well as inhibits crystal growth, thus meeting the needs of producers and consumers. The design, size, and angle of the rotary auger achieve a high level of homogenization, which also reduces raw material processing time.

- High level of homogenization, aimed at increasing stability and improving the honey's structure without altering the product's flavor.

- No dead spots or corners due to the inclined bottom of both the working tank and the auger mixer.

- The working tank is equipped with a jacket and a built-in water heating system.

- Large-diameter outlet valve installed at the lowest hydraulic point.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 4/ 7

- Loading, kg: 500/ 1100

Used in chemical, construction, cosmetic or food industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

- Volume: 50l

- Voltage: 380-400V

The dough mixer is a batch type mixing equipment, working in the opposite direction, to produce a wide range of dispersions and emulsions of varying viscosity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Stainlees steel free standing mixer for meat and dough.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1

- Principle of operation: Batch mode

- Volume: 40 60l/ 80l/ 120l

A spiral mixer with a fixed bowl and an electronic control panel. Available in various different capacities.

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 120 l/ 160 l/ 200l/ 250 l

- Voltage: 380-400V

The Y-shaped food mixer contains a double vessel with a 90┬░ apex angle. This mixing system is designed for mixing, pre-mixing liquid, viscous, dry and bulk components to obtain homogeneous mixtures.

- Special shape designed for fragile products that may break when exposed to centrifugal force

- Effective mixing of products with different components to obtain a homogeneous structure quickly and with minimal energy consumption

- Gentle mixing and tumbling due to complex random trajectories of product movement

- Compact installation

- Easy maintenance and high level of safety - safety bar with a position sensor

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 150l