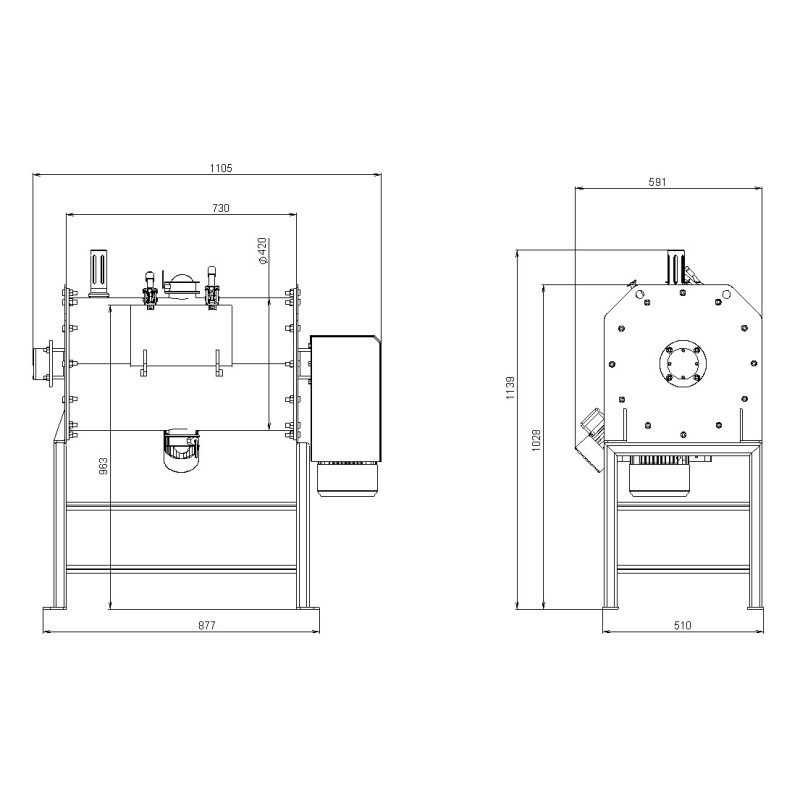

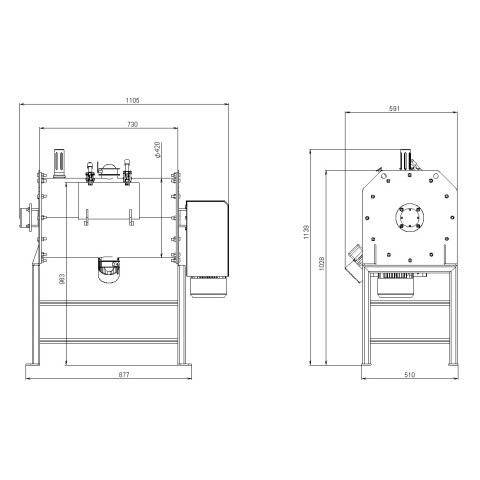

Ploughshare Mixers / Homogenizers NP 100-1800

The price depends on the selected modifications and specific options

The plow mixer is often used in the food, pharmaceutical, and chemical industries for mixing and saturating powder products with liquid media in order to obtain a high-quality mixture.

- High intensity and quality of mixing, stirring

- Short mixing time and a high productivity

- Guaranteed repeatability and reproducibility of the product batches

- Gentle handling of the product due to the mixing device's special plows

- A large number of options to choose from to fit a specific product type

- Air Purge Seals

Plow-shaped mixers are utilized in the production of seasonings, the confectionery industry, and applications requiring starch saturation. They also find use in the cosmetic and pharmaceutical industries, where it is essential to achieve a uniform mixture of components across various fractions in a batch or portion of a product.

Plow-shaped mixers allow you to process powder products and carry out the following technological processes:

|

saturation with liquid media |

granulation |

applying coating |

mixing different fractions |

|

|

|

|

Advantages:

- Pneumatic valves for product supply and unloading.

- Special air seals for the shaft and bearings.

- Hygienic design, internal surfaces ground to Ra<2 ¬Ķm.

- Large sectional hatches for service and cleaning.

- A special mixing device with specifically shaped plows that create a ‚Äúfluidized layer‚ÄĚ inside the container when the product particles are suspended under the influence of vortex flows.

- The presence of choppers/knife heads for breaking lumps when adding liquid media.

The basic version and operating principle

It comprises a cylindrical horizontal drum on a supporting structure, inside of which a mixing shaft with plows and a powerful electric drive is installed. The shape of the plows follows the shape of the working container; they rotate fairly close to the walls of the mixer. When the shaft rotates, the components are mixed along a complex path from the walls to the axis of the drum. The components/mixture moves from plow to plow along the axis of the shaft, changing the trajectory of their movement. Their peripheral speed and geometric shape are coordinated to move the product against centrifugal force while maintaining axial direction. Liquid media are supplied to the installation using special heads (spray/rotary), the installation is equipped with a filter, the cartridge of which is selected and ordered additionally depending on the type of product.

The control system is selected by the customer additionally based on the desired degree of process automation. The unit is equipped with special Air Purge Seals, which require purified air from an external source. Compressed air is also required for the pneumatic product loading and unloading valves.

Options

- Control system with varying degrees of automation

- Additional choppers/cutting heads

- Source of purified air

- Filter cartridge

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 700l/ 1200l/ 1800l

- Voltage: 380-400V

The price is indicated without the frequency converter

A twin-screw mixer for fast and intensive mixing, stirring of bulk solid products, such as granules, muesli with various powder additives.

- The mixing blades carefully move while thoroughly mixing the product

- The mixing mode allows you to move the product cyclically in a circle

- High mixing efficiency due to the counter-movement of the 2 shafts

- Compact design

- Possibility to install scrapers on each blade (optional)

- Reinforced drive, can be used for products saturated with moisture as well

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

Planetary mixers are primarily used in the confectionary industry. Offered in three different capacities.

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

An evaporating unit is utilized to remove moisture from sweet substances through heating, transforming them into concentrated syrups or solutions.

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 200 l

The Mak Mix tilting mixer is designed for preparing liquid and semi-liquid doughs. It's suitable for mixing dough for waffles, pancakes, cakes, and other baked goods.

- Made entirely out of stainless steel

- Features a tilting system with three working positions (up to 110¬į) for gravity mixing and quick emptying of the mixing bowl

- Frame mixer with a professional industrial motor

- Reinforced high-speed mixer for intensive mixing and kneading

- Safety switch on the top housing for safe operation: the mixer is switched off when the lid is opened

- Simple and easy to clean; the lid and mixer can be quickly and easily removed for cleaning

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55

- Volume: 50l/ 100l

- Voltage: 220-230V

- Stirrer speed, rpm: 35

These meat tumblers are designed for removing air and drawing moisture and marinade into the meat under the conditions of a vacuum.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 600l/ 900/ 1200l/ 2000 3000

The conical bottom mixer with a 400-liter capacity is designed for efficient mixing and smooth product discharge. Its conical shape directs contents toward the lower outlet, making it ideal for processing thicker or denser materials in an atmospheric-pressure environment.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 400l

- Voltage: 380-400V

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as a vacuum evaporator, a vacuum cooking kettle, and a unit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

These meat mixers are characterized by their modern design and strong AISI 304 stainless steel construction.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 110 l/ 163 l/ 250l/

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The new design of the universal cutter with gravity mixing is used for the production of thick and pasty products. The cutter is designed to carry out production processes such as cutting, mixing, crushing and emulsifying of various types of products to a liquid state. Thanks to the built-in duplicator, it can also be used as a device for the production of cream honey or cream honey soufflé.

- Cutting knives with a powerful 11 kW electric drive

- Frame mixing device with fluoroplastic scrapers

- Hatch opening sensor for safe maintenance

- Plexiglass hatch for visual inspection

- Duplicator for the thermal liquid around the bottom as well as the walls of the installation

- Inclined design for efficient grinding, homogenization and discharge of thick and viscous products

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 12

- Voltage: 380-400V

The KWS mixing vessel is engineered for versatile operations, including heating, cooling, and mixing of liquid products, with a maximum heating temperature of 60 ¬įC.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Geometric volume: 100 l

Suitable for mixing a small amount of dough or meat as well as other thick media.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l