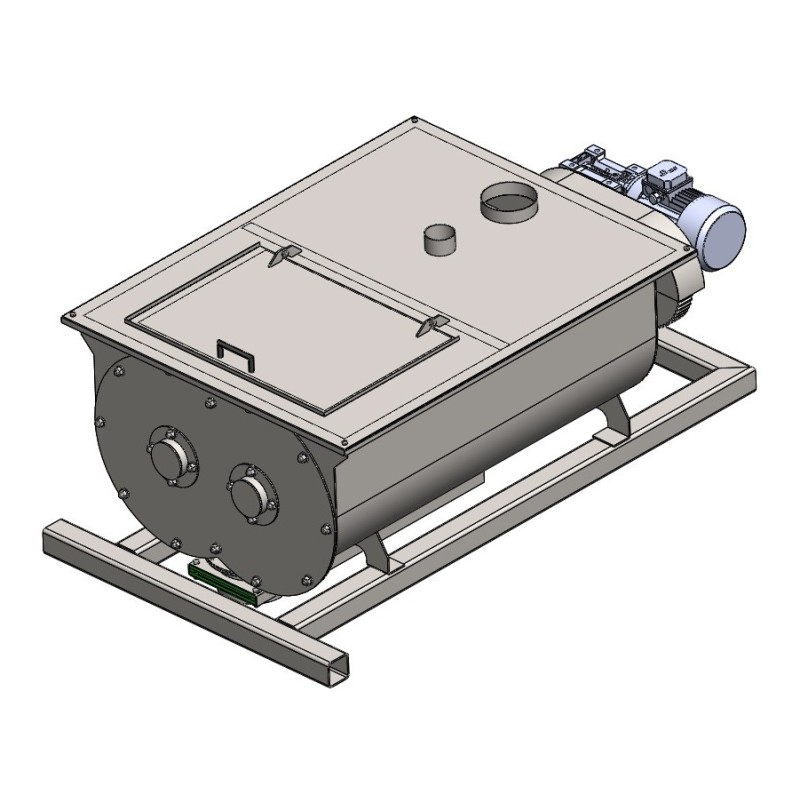

Spiral mixer TwinScrew MSH 540

The twinscrew mixer with two horizontal shafts is designed for intensive mixing and kneading dough as well as chocolate, pralines and other similar products with medium or high viscosity.

The mixer is composed of the body, which is mounted on the frame closed on all sides by the barrier. Inside the two horizontal shafts, which are arranged on the mixer, set at 60 ┬░ angle to the axes of the shafts. Blender blades may vary. This position and the presence of cylindrical holes in the blade creating conditions for efficient mixing of the ingredients.

The shafts are driven by an electric motor via a belt drive and special gear unit. The body of the mixer can be provided with a jacket which is filled with paraffin oil (heated by electric heating). The design of the mixer provides control of individual components. The mixer has a temperature sensor and an outlet. The capsule coating installation is designed for the needs of the pharmaceutical industry to create shells for tablets, granules and capsules.

Areas of use:

- Pharmaceutical industry

- Food industry

- Chemical industry

- Agricultural industry

Processes:

- impregnation

- granulation

- mixing

- massaging

Products:

- animal feed, pellets

- chocolate nuts, sunflower seeds

- granulated grains

- flour and confectionery

- pharmaceutical products (tablets)

Advantages:

- equipped with a device for easy unloading of the product;

- the introduction of the coating during the transfer for uniform application;

- production material - high quality stainless steel AISI 304/316.

The shafts are driven by an electric motor via a belt drive and special gear unit. Inside the two horizontal shafts, which are arranged on the mixer, set at 60 ┬░ angle to the axes of the shafts.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

You might also like

The NORMIT drum mixers are designed for thorough mixing for products such as combined feed for animals, infant formulas, baby food, food concentrates and additives, sports supplements and nutrients, coffee, tea, pharmaceuticals and chemical products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l/ 200l/ 500l

The mixer is designed for mixing large quantities of dough as well as meat mixtures.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 80l/ 140l

- Voltage: 380-400V

The Z-Sigma Arm paddle mixer is designed for intensive mixing, stirring, kneading and plasticizing products with high and very high viscosity, such as chewing gum base, stiff dough with low water content, toffee mass, soap base, adhesives.

- Double Z-shaped blade

- Very high shear force

- Minimum gap between z blades and the working container

- Independent electric drive for each blade

- Electric tilting for automatic unloading up to 180 degrees

- The mixer is made entirely out of food grade stainless steel AISI304

- Possibility to choose the side of tilting and unloading

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 70l/ 140/ 300l/ 460/ 700l/

- Voltage: 380-400V

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

This 800-liter capacity dissolver with a circulation pump is designed for preparing liquid solutions by dissolving substances directly in water or other working fluids. It is used in the food and beverage industries for ensuring uniform dissolution through hydrodynamic mixing in a forced recirculation loop.

Recirculation with a food-grade pump ensures rapid and uniform dissolution without sedimentation or the formation of stagnant zones. The working tank is mounted on a mobile platform with wheels, allowing for easy and quick movement between production areas.

- Fast and uniform dissolution without sediment thanks to hydrodynamic mixing

- Forced recirculation loop with product pump/inline homogenizer (optional)

- Mobile stainless steel platform on wheels

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Geometric volume: 800 l

The coating machine is designed for uniform application, impregnation of oil and fat mixture, dyes and flavors, enzymes, vitamins and other additives, various products with a high level of hygiene.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

A professional mixer for the production of mayonnaise, sauces, soups and other homogenized products. The price depends on your production capacity, as well as the technological requirements.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Geometric volume: 500 l/ 800 l

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

The industrial planetary mixer is mainly used in the confectionary industry. Available in three different sizes: 120, 140 and 170 L.

- Engine power, kW: 5,5

- Voltage: 380-400V

Mixers are carefully designed, constructed and tested to handle a variety of industrial applications that require mixing, dispersive mixing, distributive mixing and more.

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 500 l

Atmospheric cutter mixer with capacity of 150l for medium size production of confectionery, chocolate, ice cream, ready meals, cheese, cream smoothie, vegetable puree.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 150l

The mixers are made up of a double-walled cylindrical stainless steel vessel with cavity, with drain hole and 50 cm diameter butterfly valve. The cavity is filled with water which is heated by an electric resistance thermostat. The honey is mixed by blades with a marine propeller profile, adjustable in height along an oblique shaft.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55/ 1,1

- Principle of operation: Batch mode

- Volume: 100 kg / 250 kg/ 600 kg/ 1000 kg/ 2000 kg

The NDM + drum mixer is designed for thorough mixing while retaining the structure of loose products without dead zones and with relatively low consumption and short mixing time. Made for mixing products such as coffee, tea, nutrients and supplements, baby food and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

- Engine power, kW: 3

- Principle of operation: Continuous mode

- Voltage: 380-400V

The AA50 adjustable industrial mixer is designed for efficient, high-performance mixing of liquid, viscous and pasty products, as well as for dispersing dry ingredients (pigments, dyes and other materials) in a liquid medium to obtain highly dispersed suspensions, emulsions and pastes.

- Material: Stainless steel

The stirrer for mixing and stirring different types of honey comes with a stainless steel container of 50 and 100 liters. It can also be used for mixing honey during blooming, pasteurization, and controlled crystallization (creaming).

- Powerful electric drive and reinforced stirrer for thick products

- Temperature control to ensure that honey does not overheat above 40 degrees during processing

- The mixing device is also equipped with fluoroplastic scrapers

- All materials in contact with the product are made out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Continuous mode

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

Suitable for mixing a small amount of dough or meat as well as other thick mixtures.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l