Tunnel container washer REW

Our tunnel container washers are designed to wash different kinds of plastic containers.

Our tunnel container washers are designed to wash different kinds of plastic containers. The whole process of washing and disinfecting is effective and very economical.

If you strive for excellent hygiene during your production process, it is extremely important that the containers used in the production are clean. Only then can you guarantee hygiene throughout the whole process. With very little effort.

Main construction details:

- Stainless steel construction

- Closed water circulation

- Manual detergent dispenser (dose knob)

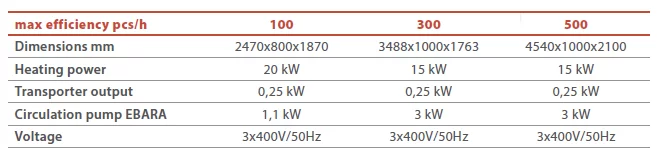

Technical Data:

- Electrical or steam power supply, oil or gas

- Closed water circulation

- Regulated rails for the different containers

- Constant width: 400mm, height: 100-350mm)

- Water filtered with the strainer

- The water from rinsing completes the washing water level

- Water connection 2 x 1/2‚ÄĚ (washing - may be supplied with hot water, rinsing ‚Äď cold water)

- Water consumption approx. 1L/container

- Optional Drying module available.

- Material: Stainless steel

- Heating power, kW: 15/ 20

- Principle of operation: Continuous mode

- Voltage: 380-400V

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

- Material: Stainless steel

- Engine power, kW: 0,75

- Voltage: 380-400V

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

The container washer for canned food is a specialized washing system designed to thoroughly clean containers used for canning food products, ensuring hygiene and sanitation standards are met within your food processing facility.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

CIP station CIP-101 With a usable capacity of 1√ó100 liters, it is used for cleaning, sanitizing and sterilizing vessels and pipes in a brewery. This type of CIP station is recommended for cleaning and sanitizing tanks from 0 to 4000 liters.

- Material: Stainless steel

- Country of origin: EU

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

CIP-102 consists of two main tanks for alkaline and acid solution and one vessel used for neutralization of solutions.

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 100l

- Voltage: 380-400V

Bubble washer for gentle washing and cleaning of fruits and berries, for example peaches, cherries, strawberries and other raw fruits prior to their further processing.

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 600 mm/ 800 mm/ 1000 mm

- Productivity: 300 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

Wheat washer, huller and separator is used for the preparation of grain for milling. Price depends on your production capacity.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

CIP-51: Equipment for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 50 liters

- Material: Stainless steel

- Country of origin: EU

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Volume: 200l

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

- Material: Stainless steel

Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with four tanks.

- Heating: Electricity Steam

- Material: Stainless steel

- Voltage: 380-400V