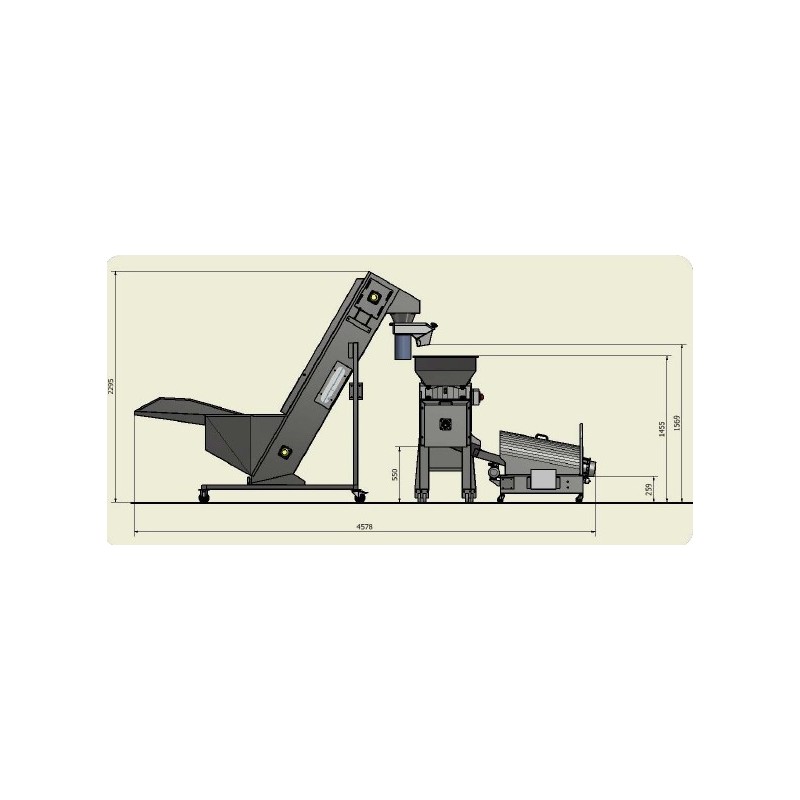

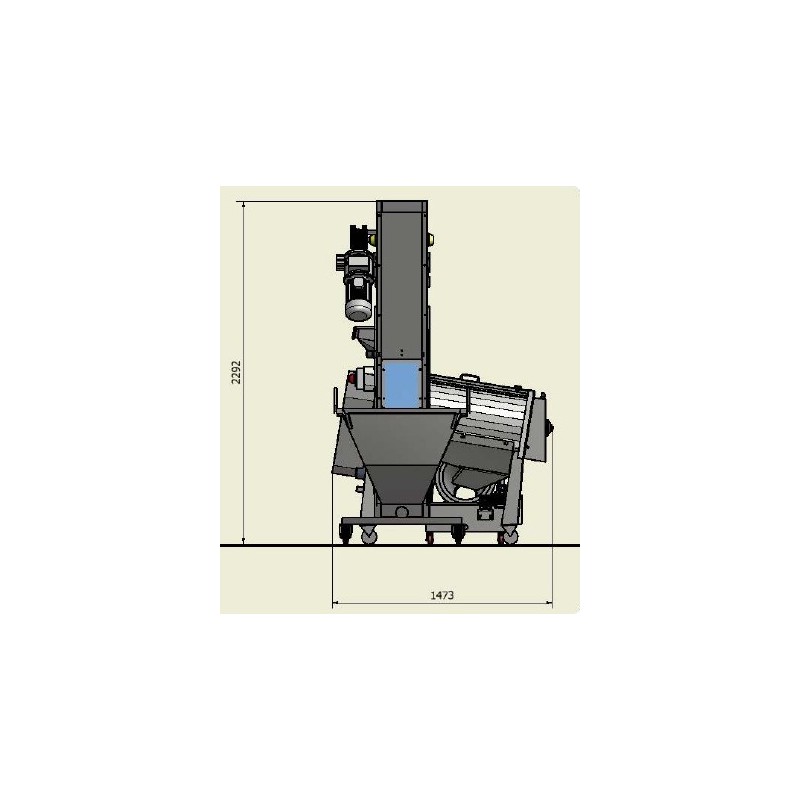

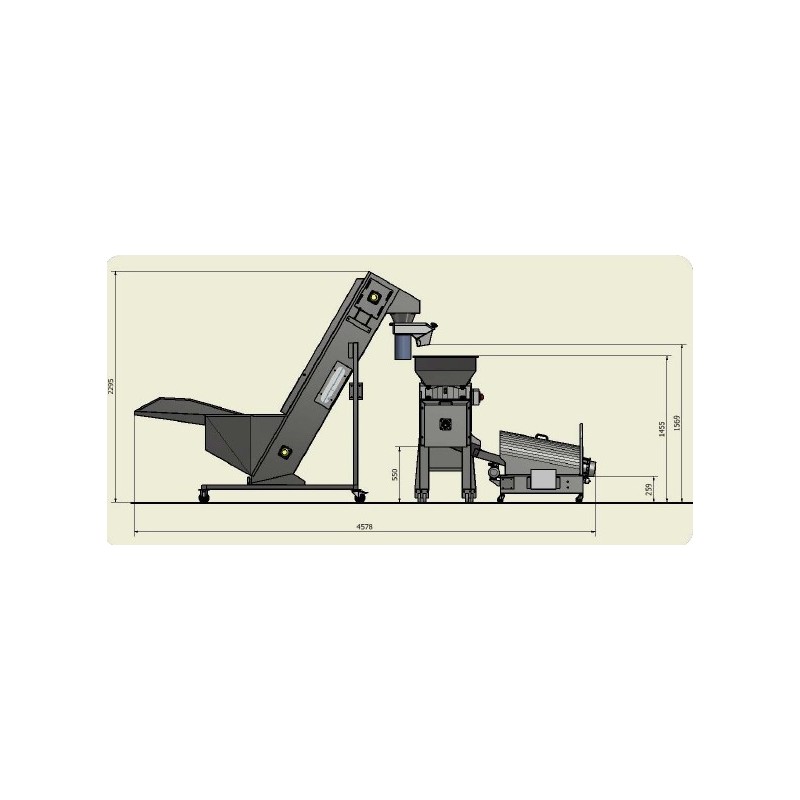

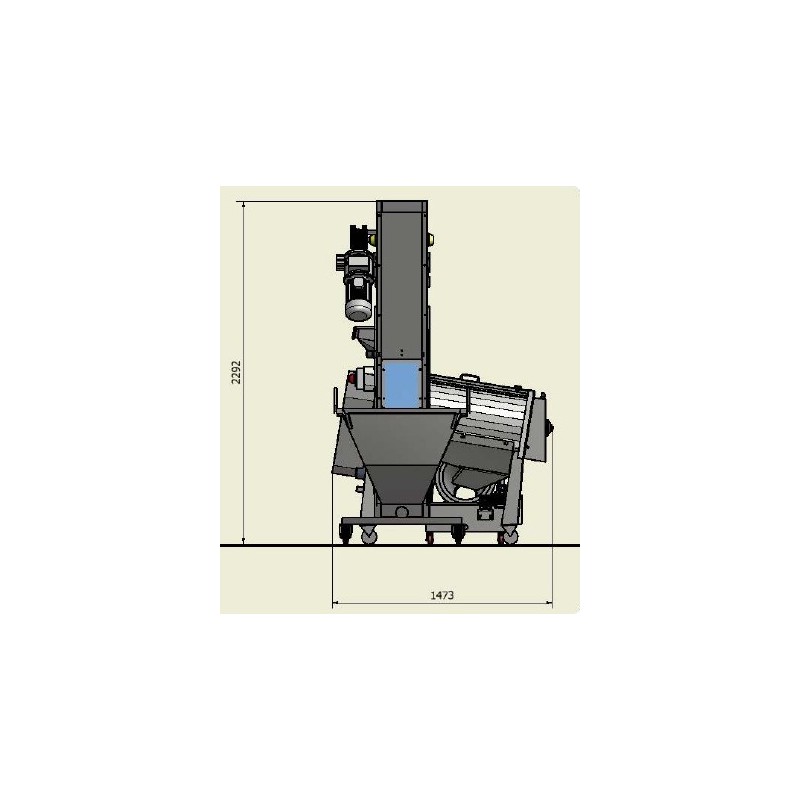

Apple processing line 1000 kg/h

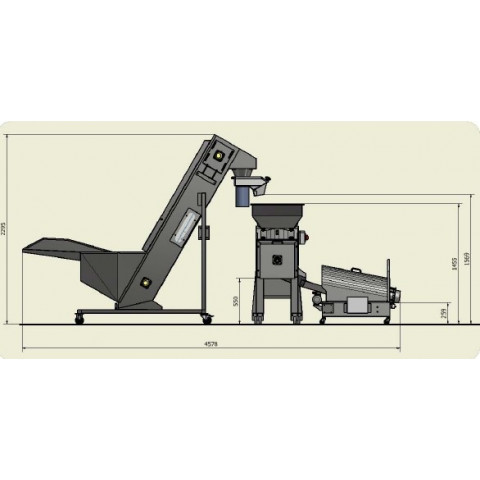

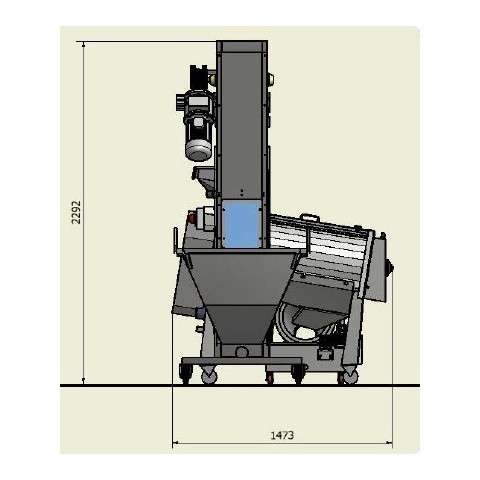

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

The process begins with the thorough washing of apples to remove all impurities. This washing takes place in a conveyor belt washer designed specifically for washing fruit.

Following this step, the cleaned apples are fed into the mill's feeding hopper. The crushed material is then transported through a destoner with the assistance of a pump, after which the entire mass undergoes meticulous filtration using a centrifugal filter. The washing device itself can achieve an output of up to 2 tons per hour, finely regulated with a speed controller. The device is mounted on a mobile structure made out of stainless steel.

Technical parameters of the apple washing and crushing line:

- Power, Kw: 8

- Voltage: 3 phases

- Loading height: 600 mm

- Unloading height: 1700 mm

- Capacity: 1000 kg / h

- Assembly weight, approx.: 550 kg

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

This jam production line allows you to get ready-made jam at the exit from whole fruits at the entrance! Equipment options may vary depending on the customer's technology.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

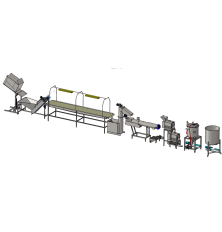

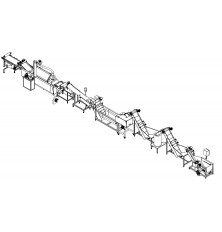

A production line for making puree from seeded fruits such as apples or pears with a processing capacity of up to 2000 kg/hour of raw materials.

- Productivity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Meatball production line comprises of a filler, automatic machine for making meatballs and batter-breading machine. Price depends on your production capacity.

- Productivity: 15 000

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Our hydrodynamic extraction line is designed for extracting various components from plant materials, including biologically active substances, proteins, fats, carbohydrates, antioxidants, dyes, and flavors.

- Effective ŌĆ£softŌĆØ continuous hydrodynamic extraction ŌĆō percolation from finely crushed raw materials.

- Extraction without the need for pre-drying the product, resulting in savings on labor and energy costs.

- Utilizing raw materials without heat treatment, preserving all of their valuable substances and enzymes.

- Possibility of performing vacuum-pulse extraction (optional).

- Additional income from processing ŌĆ£wasteŌĆØ products - extracting valuable components from pulp and pomace.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

For the price quote or more information regarding this equipment complex for the production of chocolate, please send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

Croquettes production line for making and batter breading croquettes, preparing them for frying. Croquettes from 15 to 55 grams. Produces up to 12,000 pieces/hour. We also offer a range of fryers.

Price depends on your production capacity.

- Productivity: 12 000

- Material: Stainless steel

- Principle of operation: Continuous mode

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

- Material: Stainless steel

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A complete set of equipment for the production of margarine with a capacity of up to 500 kg/hour.

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

A production line for thermostable fruit-based fillings, widely used in the production of pastries, baked goods, and various semi-finished products, as well as curd cheeses, creams, and even ice cream.

- Obtaining top-notch thermostable fillings while preserving essential nutrients and vitamins.

- Compact system featuring a unified control panel, ensuring easy and straightforward operation.

- Swift and efficient recycling included as a standard feature.

- Modular design with numerous additional options for customization.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The complex of equipment for the production of mayonnaise consists of several installations for automatic dosing, mixing, and obtaining a stable emulsion.

- Compact design, offering convenient and straightforward operation in a limited space.

- Cost-effective solution for automatic dosing without incurring high automation costs.

- A wide range of additional modular options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 13,5

- Voltage: 380-400V

The hamburger production line is designed for the production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on the production requirements.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Voltage: 220-230V

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

The concentration and thickening line line has been especially designed for industrial dairy production facilities with a small surplus of milk or smaller milk processing businesses that want to expand their product range. It has an estimated productivity of up to 50-120 kg/hour during continuous operation.

- Professional industrial technology with compact dimensions

- A large number of additional equipment and options to choose from

- Material: Stainless steel

- Principle of operation: Continuous mode

An equipment complex designed for processing raw, peeled, and blanched peanuts, offering a production capacity of up to 500 kg/hour.

- Productivity: 500 kg/h/

- Principle of operation: Continuous mode

- Country of origin: Slovakia