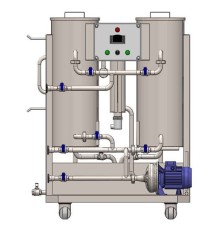

Container washer for canned food CAN WASH 1

The container washer for canned food is a specialized washing system designed to thoroughly clean containers used for canning food products, ensuring hygiene and sanitation standards are met within your food processing facility.

This product is designed for the cleaning and sterilization of glass, metal and plastic cans, glasses and similar containers.

The conveyor washer can be designed individually for each type of packaging, making it ideal for cleaning, sterilizing and drying containers of various shapes and sizes. Inner and outer side processing can be carried out simultaneously, so the machine can be used to sterilize containers before filling with the product, as well as for the final rinsing and drying of the product-filled cans after autoclave.

The washing and sterilization cans machine can be programmed to work in either an automatic or semi-automatic mode, for any capacity. Depending on the type of container and the customerŌĆÖs needs, the machine can perform in continuous mode for the following operations:

- pre-rinsing with clean water

- washing cans, using any detergents

- rinsing with clean water

- steam sterilization

- drying using compressed air

Principle of operation

Cans are loaded into the washer by the feed conveyor, inside which there is a mesh conveyor made of stainless steel. The conveyor speed is adjustable, so you can change the performance of the machine and the processing time at any stage.

Perfectly designed for the cleaning and sterilization of containers, CanWasher 1 has adjustable side limiters that allow for handling of cans with a variety of sizes.

In the first stage, cans are processed from top to bottom with a jet of high-pressure water or cleaning solution (optionally, with the detergent dosing system). In the second stage, they are rinsed with pure water, followed if necessary by steaming for sterilized cans and intensive drying with compressed air.

Control of the process of washing and sterilization of containers is carried out by means of the electronic control unit found on the logic controller, which allows the user to monitor, control and record various parameters, such as conveyor speed, temperature, the level of the cleaning solution supply tank and others factors.

The machine is designed to allow for easy disassembly, and for easy cleaning and maintenance; the top cover can be removed for easy access to internal components. The machine is made entirely of stainless steel AISI304, using European components.

Economic design

- The special design of this machineŌĆÖs nozzles, feeding water under high pressure, means the lowest possible consumption of water.

- An optional system of dosed detergent feeding is available, to prevent changes in the concentration of cleaning solutions and to ensure optimum flow.

- Waste water can either be discharged into the sewage system or used for circuit cleaning, and a facility for the reuse of water or cleaning solution can be installed.

Advantages:

- High performance in a limited area

- Versatility of use in the selection of functions

- Flexible settings for different types of containers

- Continuity of the process, providing a unified, high quality treatment for all cans

- Economy in terms of use of energy, water and detergent

- Easy integration into any production process

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

You might also like

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

Compact universal washing and spin-drying unit designed for gentle and effective cleaning of fruits and vegetables. The system combines adjustable whirlpool washing with centrifugal drying, allowing efficient removal of soil, dust, and water in just a few minutes. Constructed entirely from food-grade stainless steel, it ensures hygienic operation and easy cleaning. Ideal for restaurants, hotels, catering kitchens, and small food processors.

- Efficient combined washing and drying process - total cycle under 5 minutes

- Adjustable washing intensity for delicate or firm products

- Stainless steel perforated drum for thorough cleaning and durability

- Integrated spin dryer for quick water removal and extended product shelf life

- Compact, easy-to-clean design with low water and energy consumption

We offer a wide range of washing equipment tailored to diverse food products, ensuring optimal cleanliness and preparing your fruits and vegetables for the next processing stage.

- Productivity: 2000 kg/h 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

We offer different types of washing equipment for various different fruits and vegetables.

- Productivity: 1500 kg/h

- Material: Stainless steel

- Engine power, kW: 3

- Weight: 200

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

- Material: Stainless steel

- Engine power, kW: 0,75

- Voltage: 380-400V

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V

The washer-auger-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

Price depends on your product and the production capacity. For more information, send us a request.

- Productivity: 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

Our tunnel container washers are designed to wash different kinds of plastic containers.

- Material: Stainless steel

- Heating power, kW: 15/ 20

- Principle of operation: Continuous mode

- Voltage: 380-400V

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

Wheat washer, huller and separator is used for the preparation of grain for milling. Price depends on your production capacity.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

Clean-in-place (CIP) is a method of cleaning and disinfecting the internal surfaces of pipes, containers, water tanks as well as industrial equipment, filters, related fittings and other accessories without the need for disassembly.

- Material: Stainless steel

- Volume: 2x50 l/ 2x100 l/

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1