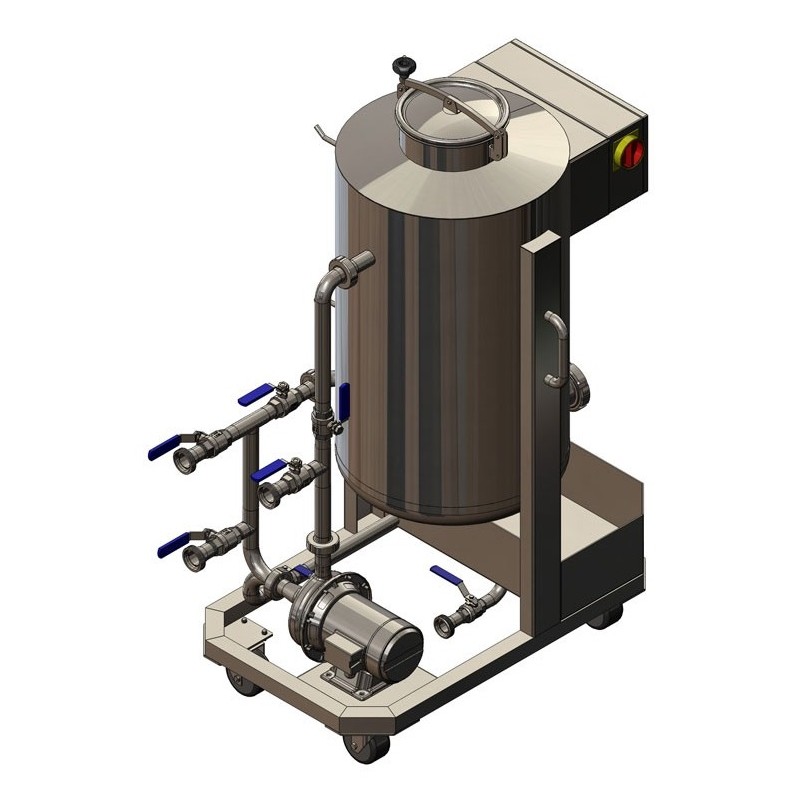

Cleaning and disinfection station CIP-201

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

CIP-201 is a mobile machine for cleaning and sterilizing vessels and pipelines.

It is a fully equipped system for breweries and other food productions. CIP equipment heats and circulates alkaline and acid solutions using a pumping system, hoses and a sanitary shower that sprays sanitary chemical solutions onto the internal walls of the sanitized tank. The device consists of one stainless steel tank with a nominal volume of 200 liters and one neutralization tank (70 liters), one centrifugal pump, electric control panel, manual valves and all installation pipes. Digital temperature control in the range of 0-80┬░C. This type of CIP station is recommended for the cleaning and disinfection of fermentation tanks, storage tanks, water tanks from 0 to 8000 liters, as well as all pipelines and other objects that come into contact with drinks or food products.

Tank functions:

- Alkaline or acid tank for alkaline cleaning - sanitation of all brewery equipment

- Neutralization tank to neutralize acidic and alkaline solutions before they enter the sewer.

Equipment CIP-201 is mounted on a rigid frame, equipped with wheels that can be fixed. The material used is stainless steel 1.4301 (AISI 304) or 1.4404 (AISI 316) according to the option chosen. The container is not insulated, the internal parts of the pump and the heating chambers are made of AISI 316 stainless steel. The pipes, fittings, frame and tanks are made of AISI 304 stainless steel.

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

The principle of the cleaning and disinfection process is based on the circulation of an alkaline or acidic solution through a sanitary shower, spraying it onto the walls of the vessel and into its space. It also features an instantaneous heater with digital temperature control ranging from 0┬░C to 80┬░C.

The CIP consists of one main tank for alkaline or acid solution and one vessel used for neutralizing the solutions. Circulation of sanitary solutions.

Description of sanitation cleaning cycle

The cleaning-sanitization cycle usually consists of the following steps:

- Pre-rinsing - washing the production equipment with cold or hot water.

- Cleaning - cleaning of production equipment using recycled hot water.

- Rinse - thorough rinsing of production equipment with cold or hot water.

- Chemical disinfection (sanitary) - washing equipment with an alkaline and then an acid disinfectant solution of the required concentration.

- Rinse - thorough rinsing of production equipment with cold or hot water.

- Neutralization - performed after completion of several cycles of cleaning and disinfection - mixing an alkaline and then an acidic disinfectant solution to achieve a neutral pH of the solution and discharge them into the sewer.

Options:

- Width 1 150 mm

- Height 1850 mm

- Depth 750 mm

- Container for NAOH or H2SO 290 liters

- Boiler 12 l

- Heating elements 3x 2000 W

- Neutralization vessel 70 l

- Distribution pipe DN 32

- Anchors (outlets / inlets) DN 32, 1.4301

- Centrifugal pump type EBARA CD / I 90 / 10 IE3, 0.75kW 90 l / min, 230V / 50Hz (AISI 316L)

- 1 PC. - CIP self-cleaning ball

- Electrical switchboard

- Main electrical connection 3 * 400V / 50Hz 16A

- Circuit breaker 230V 16A

- Digital regulator Dixel XR 10 D

- Heating contactor 230V 16A

- Engine starter 230V

- Sampler NTC 6 mm

- Cable 5x 2.5 5m

- Inlet (suction part) GG DN 32

- Outlet (part of delivery) GG DN 32

Technological scheme of the CIP-201 station connected to an external tank for cleaning and disinfection:

- Black marked - standard equipment of CIP station

- Marked in blue - optional self-cleaning kit (can be used for self-cleaning CIP station)

- Orange marked - optional hose cleaning kit (can be used to clean hoses and pipes

Standard Equipment:

- Tank A: Alkaline / acid tank for cold alkaline cleaning and sanitation of all brewing equipment.

- Tank B: a tank for neutralizing acidic and alkaline solutions before they are discharged into the sewer.

- Pump: EBARA circulation pump

- Heaters: electric heating elements in separate chambers

- V1: tank filling valve A

- V2: Valve for sucking disinfectant solution from tank A into the pump

- V3: Tank A drain valve

- V5: Valve open/close water inlet

- V6: valve for opening/closing the sanitizing outlet

- V7: valve for opening/closing the sanitizing solution inlet

- V8: Tank drain valve B

Self-cleaning kit (accessory):

- V9: Tank cleaning valve A

- V10: valve for sucking disinfectant solution from tank B into the pump

- Spray ball in tank A

- Spray ball in tank B

Ingress Cleaning Hose (Optional Equipment):

- F1: Fitting for connecting the hose for the outlet of the disinfectant solution (cleaning the hose or pipe)

- F3: Fitting for connecting the hose for the inlet of the disinfectant solution (return from the disinfected hose or pipe)

- V3: Valve for opening / closing the outlet of the disinfectant solution (cleaning the hose or pipe)

- V4: Separating valve for cleaning hoses and pipes.

- Material: Stainless steel

- Engine power, kW: 0,75

- Voltage: 380-400V