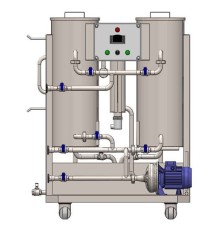

Cleaning and disinfection station 4 tanks

Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with four tanks.

Cleaning and disinfection stations with four tanks are installations for cleaning and sterilizing vessels and pipelines.

These are complete systems for breweries and other food industries. CIP equipment heats and circulates water, alkaline and acid solutions through a sanitary shower that sprays sanitary chemical solutions onto the tank wall. The device consists of four separate tanks and one neutralization tank, one or two centrifugal pumps, manual and automatic valves, and all installation pipes. The steam version of the CIP station also includes a tubular heat exchanger (heated with hot steam by an external steam generator) with digital temperature control in the range of 0-80 ┬░ C. This type of CIP station is recommended for cleaning and sanitizing tanks with a volume of more than 6000 liters.

The main advantage of the four-tank CIP system is two separate tanks - the first tank is for caustic cleaning of the brewhouse, the second tank is for caustic cleaning of other brewing equipment (tanks, filters, pipesŌĆ”). The material used is stainless steel 1.4301 (AISI 304) or 1.4404 (AISI 316) depending on the option chosen. Tanks (vessels) are not insulated.

Two options for the heating system:

- S: Version with steam generator - Heating must be provided by an external steam generator, which is not included in the price.

- E: Electric version - Heating is provided by internal electric heating elements which are included in the price.

Tank functions:

- First alkaline tank: alkaline cleaning of the brewhouse

- Second alkaline tank: alkaline cleaning of other brewing equipment (tanks, filter, pipes...)

- Acid vessel: acid cleaning and sanitation of all brewing equipment

- Water tank: collecting and heating water

- Neutralization vessel: neutralization of acidic and alkaline solutions before they are discharged into the sewer.

The equipment is mounted on a rigid frame with fixed wheels, constructed from stainless steel 1.4301 (AISI 304). Containers (tanks) are not insulated. Pump internals and heating chambers are crafted from AISI 316 stainless steel, while pipes, fittings, frames, and tanks are composed out of AISI 304 stainless steel.

Description of sanitation cleaning cycle

The cleaning-sanitization cycle usually consists of the following steps:

- Pre-rinsing - washing the production equipment with cold or hot water.

- Cleaning - cleaning of production equipment using recycled hot water.

- Rinse - thorough rinsing of production equipment with cold or hot water.

- Chemical disinfection (sanitary) - washing equipment with an alkaline and then an acid disinfectant solution of the required concentration.

- Rinse - thorough rinsing of production equipment with cold or hot water.

- Neutralization - performed after completing several cycles of cleaning and disinfection - mixing an alkaline and then an acidic disinfectant solution to achieve a neutral pH of the solution and drain them into the sewer┬Ā

- Heating: Electricity Steam

- Material: Stainless steel

- Voltage: 380-400V

You might also like

Clean-in-place (CIP) is a method of cleaning and disinfecting the internal surfaces of pipes, containers, water tanks as well as industrial equipment, filters, related fittings and other accessories without the need for disassembly.

- Material: Stainless steel

- Volume: 2x50 l/ 2x100 l/

CIP-51: Equipment for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 50 liters

- Material: Stainless steel

- Country of origin: EU

CIP-102 consists of two main tanks for alkaline and acid solution and one vessel used for neutralization of solutions.

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 100l

- Voltage: 380-400V

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

- Material: Stainless steel

- Engine power, kW: 0,75

- Voltage: 380-400V

The container washer for canned food is a specialized washing system designed to thoroughly clean containers used for canning food products, ensuring hygiene and sanitation standards are met within your food processing facility.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

Clean-in-place (CIP) is a method of cleaning and disinfecting the internal surfaces of pipes, containers, water tanks as well as industrial equipment, filters, related fittings and other accessories without the need for disassembly.

- Material: Stainless steel

- Volume: 2x50 l/ 2x100 l/

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

The destoner lift machine is designed for pre-washing and transporting root vegetables such as potatoes, carrots, beets, and other similar vegetables. After rinsing, the auger destoner separates floating particles like leaves and stems in the receiving hopper, while the product is conveyed up to the discharge height using a screw lift.

- Allows you to separate stones, leaves from root vegetables

- Pre-washing of root vegetable crops

- Two functions in one unit: washing and transporting

- Spacious hopper/tub for loading the product

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This open tank is intended for washing the juice tanks. Kapacity 250L.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Volume: 250l/

CIP station CIP-101 With a usable capacity of 1├Ś100 liters, it is used for cleaning, sanitizing and sterilizing vessels and pipes in a brewery. This type of CIP station is recommended for cleaning and sanitizing tanks from 0 to 4000 liters.

- Material: Stainless steel

- Country of origin: EU

Vegetable washers are designed to clean and prepare vegetables for consumption or further processing.

We offer different types of vegetable washers.

- Material: Stainless steel

- Engine power, kW: 0,47 / 1,45 / 1,85

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 160 l/ 300l/ 600l/