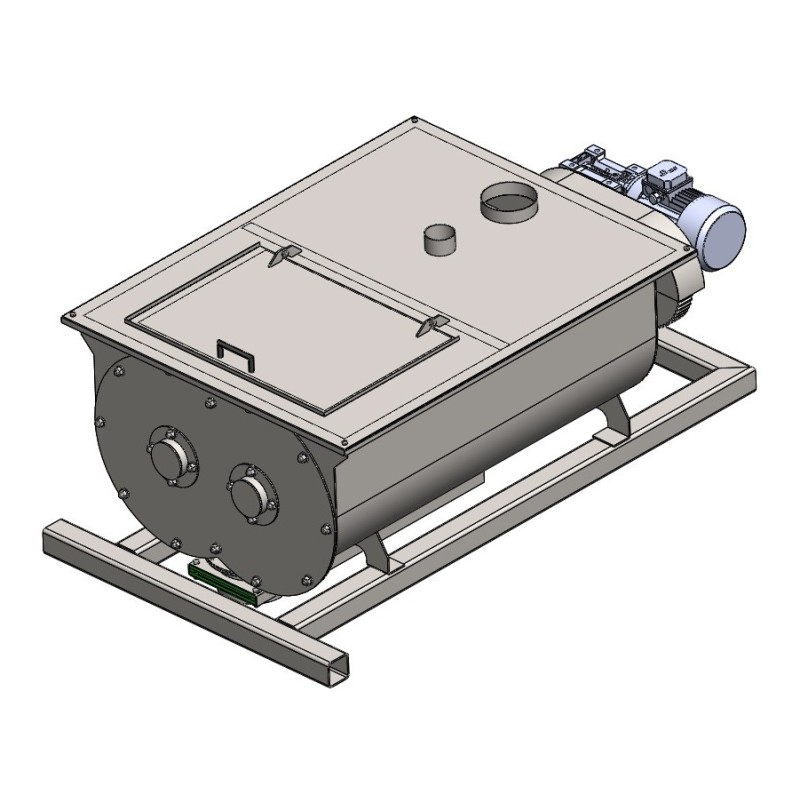

Spiral mixer TwinScrew MSH 540

The twinscrew mixer with two horizontal shafts is designed for intensive mixing and kneading dough as well as chocolate, pralines and other similar products with medium or high viscosity.

The mixer is composed of the body, which is mounted on the frame closed on all sides by the barrier. Inside the two horizontal shafts, which are arranged on the mixer, set at 60 ┬░ angle to the axes of the shafts. Blender blades may vary. This position and the presence of cylindrical holes in the blade creating conditions for efficient mixing of the ingredients.

The shafts are driven by an electric motor via a belt drive and special gear unit. The body of the mixer can be provided with a jacket which is filled with paraffin oil (heated by electric heating). The design of the mixer provides control of individual components. The mixer has a temperature sensor and an outlet. The capsule coating installation is designed for the needs of the pharmaceutical industry to create shells for tablets, granules and capsules.

Areas of use:

- Pharmaceutical industry

- Food industry

- Chemical industry

- Agricultural industry

Processes:

- impregnation

- granulation

- mixing

- massaging

Products:

- animal feed, pellets

- chocolate nuts, sunflower seeds

- granulated grains

- flour and confectionery

- pharmaceutical products (tablets)

Advantages:

- equipped with a device for easy unloading of the product;

- the introduction of the coating during the transfer for uniform application;

- production material - high quality stainless steel AISI 304/316.

The shafts are driven by an electric motor via a belt drive and special gear unit. Inside the two horizontal shafts, which are arranged on the mixer, set at 60 ┬░ angle to the axes of the shafts.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

You might also like

The NORMIT drum mixers are designed for thorough mixing for products such as combined feed for animals, infant formulas, baby food, food concentrates and additives, sports supplements and nutrients, coffee, tea, pharmaceuticals and chemical products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l/ 200l/ 500l

The mixer is designed for mixing large quantities of dough as well as meat mixtures.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 80l/ 140l

- Voltage: 380-400V

The Z-Sigma Arm paddle mixer is designed for intensive mixing, stirring, kneading and plasticizing products with high and very high viscosity, such as chewing gum base, stiff dough with low water content, toffee mass, soap base, adhesives.

- Double Z-shaped blade

- Very high shear force

- Minimum gap between z blades and the working container

- Independent electric drive for each blade

- Electric tilting for automatic unloading up to 180 degrees

- The mixer is made entirely out of food grade stainless steel AISI304

- Possibility to choose the side of tilting and unloading

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 70l/ 140/ 300l/ 460/ 700l/

- Voltage: 380-400V

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The industrial mixing and homogenizing equipment is well-suited for small and medium-sized production enterprises engaged in the processing of food, cosmetics, and various chemicals.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The laboratory vacuum cutter mixer is designed for uniform grinding, emulsifying and mixing of food, cosmetic and pharmaceutical products, chemical mixtures with the addition of oil, dyes, concentrates or liquid flavors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

This mixing machine is intended for mixing┬Āsauerkraut with carrots, beets, salt, spices, also for salad, kimchi mixing etc.

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l/ 600l/

Suitable for mixing a small amount of dough or meat as well as other thick mixtures.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

The new design of the universal cutter with gravity mixing is used for the production of thick and pasty products. The cutter is designed to carry out production processes such as cutting, mixing, crushing and emulsifying of various types of products to a liquid state. Thanks to the built-in duplicator, it can also be used as a device for the production of cream honey or cream honey souffl├®.

- Cutting knives with a powerful 11 kW electric drive

- Frame mixing device with fluoroplastic scrapers

- Hatch opening sensor for safe maintenance

- Plexiglass hatch for visual inspection

- Duplicator for the thermal liquid around the bottom as well as the walls of the installation

- Inclined design for efficient grinding, homogenization and discharge of thick and viscous products

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 12

- Voltage: 380-400V

The cooking boiler is equipped with a jacket for heating as well as a heating system, an electrically driven stirrer (with a geared motor) and Teflon scrapers, which allow for the processing of products with low to medium viscosity. The cooking device is also equipped with a vacuum system.

- Productivity: 100l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Working volume: 50-80l