Spiral mixer TXF

A spiral mixer with a fixed bowl and an electronic control panel. Available in various different capacities.

The machine is mainly used for mixing different types of ingredients to obtain dough.

All ingredients can be put info the bowl and mixed same type (depends on your recipe) After the end of the mixing, the bowl will change the rotations to separate the dough from the spiral.

Advantages:

- The bowl and spiral are made of stainless steel

- All modes have two rotation speeds

- Two engines - for mixing the drought and turning the bowl

| Model | Weight range kg | Amount of flour kg | Bowl capacity L┬Ā | Power kW | Power supply, V | Weight kg | Dimensions LxWxH cm |

| 60 | 6-60 | 36 | 117 | 4,25 | 400V 50 Hz | 345 | 113x70x139 |

| 80 | 8-80 | 50 | 131 | 5,35 | 400 V 50 Hz | 350 | 113x70x139 |

| 120 | 10-120 | 75 | 189 | 5,75 | 400 V 50 Hz | 505 | 125x78x150 |

| 160 | 10-160 | 100 | 266 | 11,05 | 400 V 50 Hz | 695 | 150x88x158 |

| 200 | 10-200 | 125 | 306 | 11,05 | 400 V 50 Hz | 705 | 155x94x158 |

| 250 | 14-250 | 150 | 378 | 13,1 | 400 V 50 Hz | 755 | 161x104x161 |

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 120 l/ 160 l/ 200l/ 250 l

- Voltage: 380-400V

A rotating drum unit designed for continuous coating and seasoning operations as well as product saturation with spices and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

This mixing machine is intended for mixing┬Āsauerkraut with carrots, beets, salt, spices, also for salad, kimchi mixing etc.

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l/ 600l/

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

Stainlees steel free standing mixer for meat and dough.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1

- Principle of operation: Batch mode

- Volume: 40 60l/ 80l/ 120l

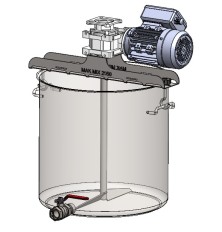

The mixers are made up of a double-walled cylindrical stainless steel vessel with cavity, with drain hole and 50 cm diameter butterfly valve. The cavity is filled with water which is heated by an electric resistance thermostat. The honey is mixed by blades with a marine propeller profile, adjustable in height along an oblique shaft.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55/ 1,1

- Principle of operation: Batch mode

- Volume: 100 kg / 250 kg/ 600 kg/ 1000 kg/ 2000 kg

Vacuum paddle mixers are designed for fast and precise mixing meat-mass in a vacuum. Used in meat production in meat processing factories.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 3000

A detachable lid with an automatic food stirrer for stainless steel 40 cm pots, suitable for volumes of 50 and 100 liters. An automatic stirrer allows you to mix and stir various products, including during thermal processing. The type of mixing device can be additionally selected depending on the required process.

- Professional industrial single-phase motor for 220-230 Volts

- The control is located directly on the motor housing or on the drive cable

- Easy and simple installation and fixation of the lid on the pan

- Suitable for standard 40 cm pots with a capacity of 50 or 100 liters

- The lid and stirrer are made entirely out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Voltage: 220-230V

The coating machine is designed for uniform application, impregnation of oil and fat mixture, dyes and flavors, enzymes, vitamins and other additives, various products with a high level of hygiene.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

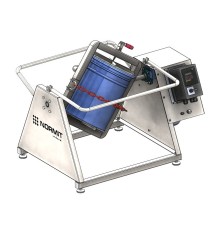

Barrel mixers are used to mix a wide range of loose and granular products in a shipping/barrel container. The available mixer models are suitable for the following volumes:

ConMix 20 - 20-30 liter standard drums with a diameter of 316 mm, adjustable frame structure height

ConMix 75 - 48-65 liter standard barrels with a diameter of 400 mm, adjustable frame structure height

- It is possible to use standard food containers ranging from 20-65 liters

- Easy control via a frequency converter as a stand-alone control panel

- Safe operation thanks to a roll bar with a position sensor

- Engine power, kW: 0,37/ 0,55/ 1,1

- Volume: 20l/ 75/ 100l

The 50 liter mixer Mak Mix is a universal mixer for mixing, stirring, kneading various solutions and mixtures. Equipped with an easily removable mixing device and a tilting system of the working bowl.

- Gravity mixing which is 40% more efficient, is possible due to the ability to adjust the tilt angle of the working container

- Simple and convenient design for maintenance - compact installation

- Independent stainless steel supporting structure

- Easily removable lid with a mixing device

- Special small elongated protrusion - spout on the edge of the working container for convenient draining and unloading of the product

- Tilt angle for unloading - 110 degrees

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

Industrial churning machine available in two capacities. Simple production of butter.

- Geometric volume: 30 l/ 70 l

The new design of the universal cutter with gravity mixing is used for the production of thick and pasty products. The cutter is designed to carry out production processes such as cutting, mixing, crushing and emulsifying of various types of products to a liquid state. Thanks to the built-in duplicator, it can also be used as a device for the production of cream honey or cream honey souffl├®.

- Cutting knives with a powerful 11 kW electric drive

- Frame mixing device with fluoroplastic scrapers

- Hatch opening sensor for safe maintenance

- Plexiglass hatch for visual inspection

- Duplicator for the thermal liquid around the bottom as well as the walls of the installation

- Inclined design for efficient grinding, homogenization and discharge of thick and viscous products

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 12

- Voltage: 380-400V

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Geometric volume: 500 l/ 800 l

These meat tumblers are designed for removing air and drawing moisture and marinade into the meat under the conditions of a vacuum.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 600l/ 900/ 1200l/ 2000 3000