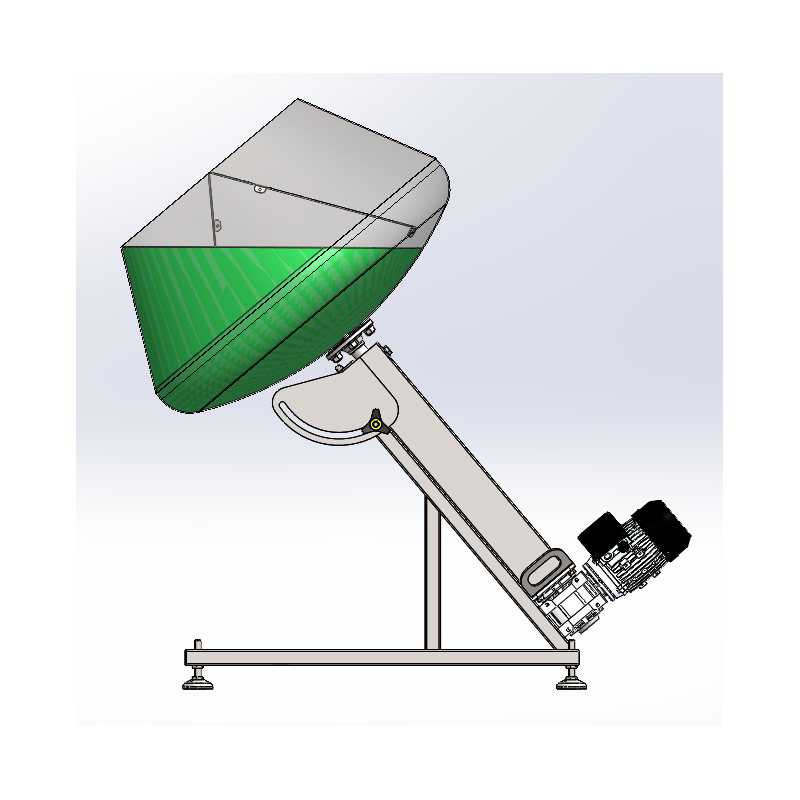

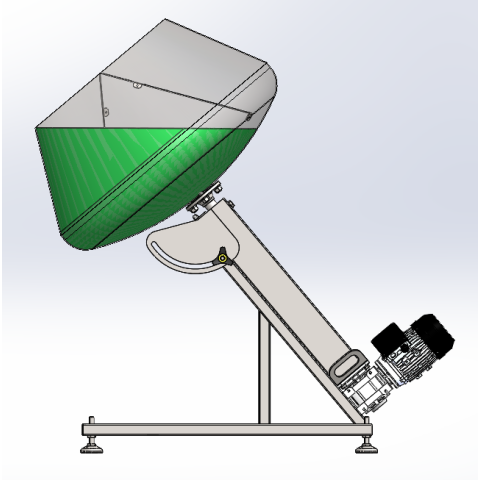

Drum coating / mixing machine NDM 100

The periodic drum coating/seasoning machine is designed to saturate and infuse a diverse range of products with flavorful aromas, vitamins, and various taste additives. It is utilized in the production of snacks, chips, cereals, and nuts, offering a wide array of flavor enhancements.

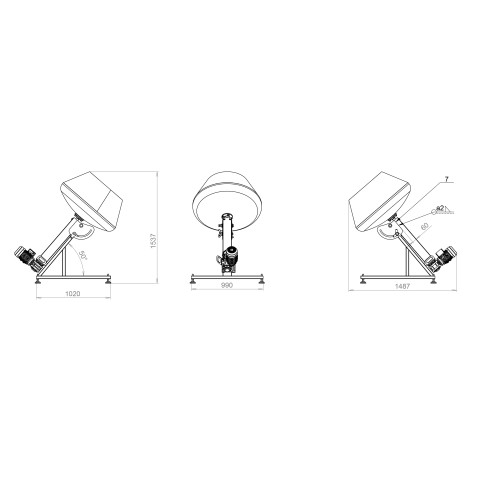

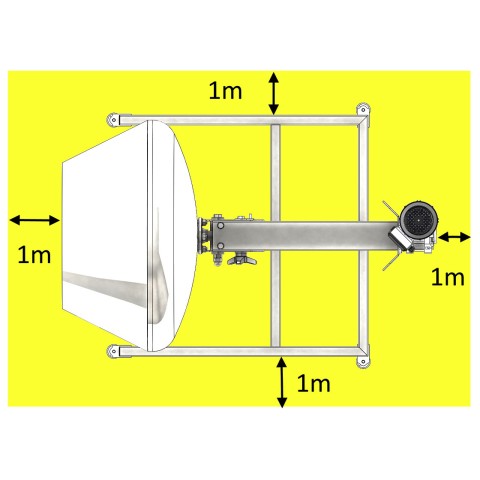

- Mechanical system for tilting the working bowl with fixation points in intermediate positions

- Special perforated blades for gentle product turning

- Powerful drum rotation drive

- Entirely made out of food grade stainless steel AISI304

- Easy control via an inverter (optional): speed control and reverse

The coater provides a special function - adding seasonings, salt, sugar and various other ingredients such as cinnamon, vanilla, spices and much more.

The drum enrobing machine ensures high-quality results and easy operation when coating or saturating the products with flavoring additives and seasonings:

|

|

|

|

Advantages:

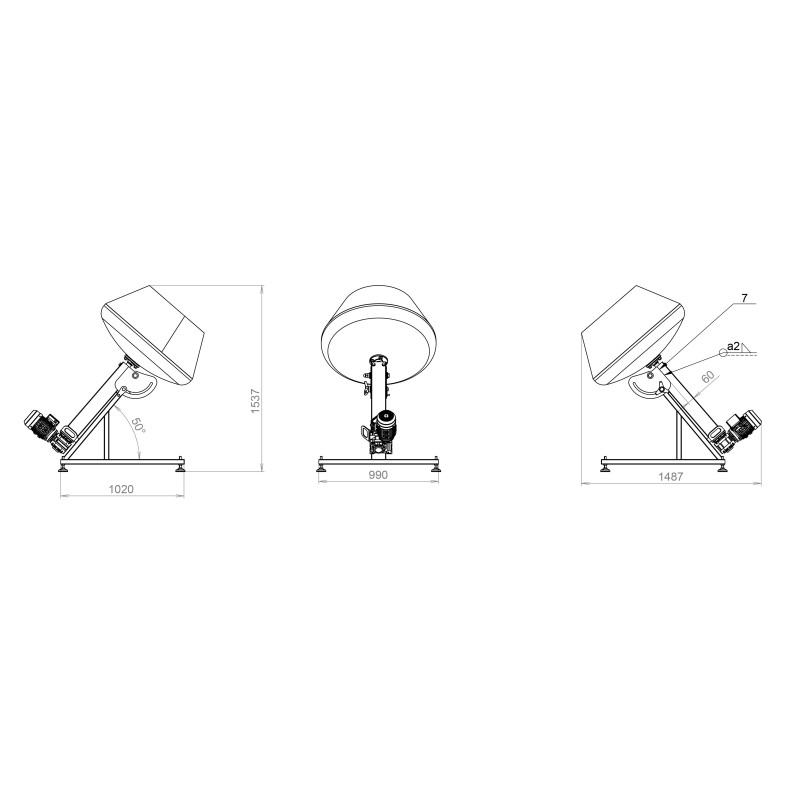

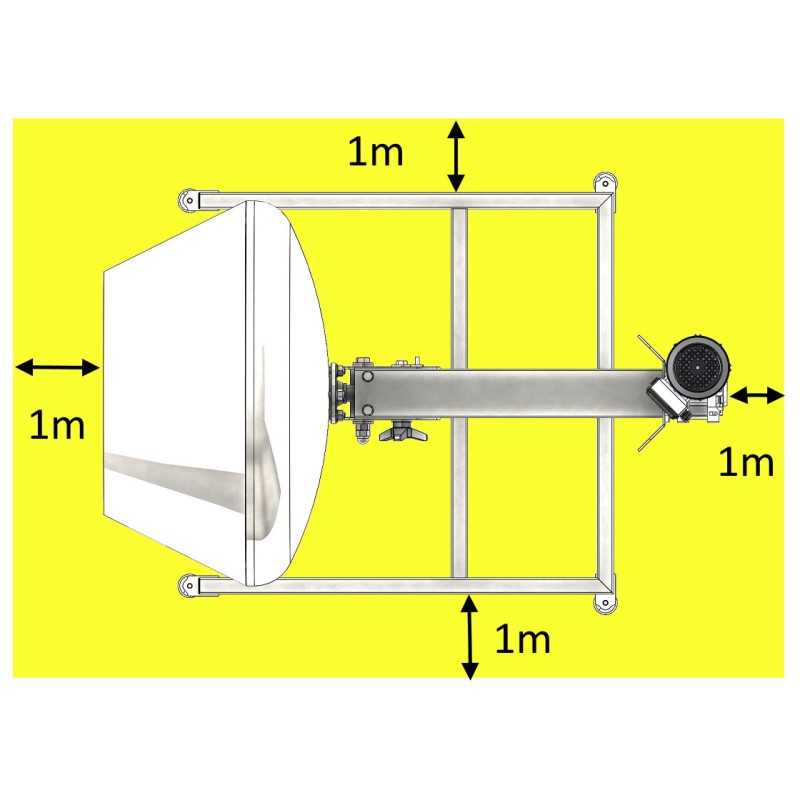

- Simple and convenient unloading of the finished product is facilitated by the handles positioned on the sides of the middle shaft. The design ensures that minimal physical exertion is needed to mechanically tilt the working bowl, even when it's loaded with the product.

- A half-moon adjustment allows for selecting the optimal drum inclination angle based on volume, product type, and processing requirements.

- The position is secured using a hand wheel; tilting the working container to its maximum position ensures a swift release of the product with minimal loss.

Basic version:

It consists of a working container (drum) with inbuilt blades, mounted on a supporting frame with a drive (geared motor) and a mechanical drum tilting system. This type of drum coating machine involves the manual loading of both the product and flavoring spices/impregnations into the drum.

The operating principle is grounded in the mixing of the product in the drum with flavoring spices/impregnations; through the rotation, the seasoning is evenly distributed throughout the drum, where it adheres to the product, and after maximum saturation, it is subsequently unloaded from the drum by tilting the working bowl.

Options:

- Frequency converter to adjust the speed as an independent control panel

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 0,55

Drum seasoning / mixing machine

You might also like

Compact, reliable, and easy to use. The frequency converter ensures smooth starting and stopping of the device's motor, reducing inrush currents, and adjusting the motor speed. It can also be connected to your smartphone via Bluetooth for convenient configuration and parameter adjustment.

Key benefits:

- Precise digital control at the touch of a button.

- Application macros.

- Switch between Industrial, Pump, and Fan modes for optimized operation.

- It is used and mounted directly on the equipment, eliminating the need for electrical cabinets. It can also be wall-mounted.

We also offer programming and installation of the frequency converter to ensure seamless integration and optimal functionality for your equipment.

- Type of the equipment: Optional equipment

Batter breading machines are designed for batter breading products such as meatball, hamburgers, soya, vegetarian burgers, croquettes, vegetables and other products. The machine is suitable for catering companies as well as big productions.

- Material: Stainless steel

- Country of origin: EU

- Working Area Width: 240 mm/ 350 mm

A rotating drum unit designed for continuous coating and seasoning operations as well as product saturation with spices and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

Automatic enrobing unit for the production of chocolate truffles.┬ĀFor more information, send us a request.

- Productivity: 50 kg/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Working Area Width: 180 mm

- Voltage: 220-230V

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 255 kg

- Volume: 500l

- Voltage: 380-400V

- Geometric volume: 170 l

- Dimensions, mm: 2350 x1500 x2000

Whether you are a small kitchen or have bigger production capacity, we are able to offer complete solution.

- Productivity: 2000-3000 ks

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Weight: 110

- Working Area Width: 150 mm

- Voltage: 220-230V

The device was primarily designed to increase dough adhesion (adhesion) by using a thin layer of dust - flour. The device is available in four widths of 200, 300, 400 and 600 mm.

Vacuum diffusion - the process in which the air inside the product is removed by vacuum and the released pores are filled with flavor, vitamins or other ingredients.

- Material: Stainless steel

- Country of origin: Slovakia

- Geometric volume: 350 l/ 700 l

The coating machine is designed for uniform application, impregnation of oil and fat mixture, dyes and flavors, enzymes, vitamins and other additives, various products with a high level of hygiene.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

This machine is used to produce sweets coated with chocolate.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 7l/ 16

- Voltage: 220-230V

Breadcrumb breading has never been easier. This device is available in various belt width configurations of 200, 300, 400 and 600 mm.

- Material: Stainless steel

- Working Area Width: 300 mm 400 mm 600 mm

- Voltage: 380-400V

A vacuum diffuser is a device used in the food industry to remove oxygen from a product under vacuum conditions, primarily employed for enhancing the preservation of food by reducing oxidation and extending shelf life.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 200l/ 1000l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Batter breading machines are designed for batter breading products such as meatball, hamburgers, soya, vegetarian burgers, croquettes, vegetables and other products. Whether you are a small kitchen or have bigger production capacity, we are able to offer complete solution.

The price depends on your production capacity.┬Ā

- Productivity: do 2000 ks

- Material: Stainless steel

- Weight: 55

- Working Area Width: 150 mm

- Voltage: 220-230V

- Dimensions, mm: 1770x899x997

The machine is available in four belt widths of 200, 300, 400 and 600 mm.

- Material: Stainless steel

- Working Area Width: 300 mm 400 mm 600 mm

- Voltage: 380-400V

The salting machine is designed for the continuous feeding and dispensing of salt or seasoning onto food products, it is recommended to install it above a conveyor belt.

- Simple controls

- Spacious hopper - up to 25 kg

- Simple and easy installation

- Height-adjustable salting machine supports

- Built-in control panel for adjusting the speed and volume of salt supplied

- Material: Stainless steel

- Engine power, kW: 0,55

- Working Area Width: 500 mm

- Voltage: 220-230V

This machine is made for the production of coated sweets. This can include roasted sugar around almond nuts.

For more information, send us a request.

- Material: Stainless steel

- Engine power, kW: 0,17/ 0,37

- Principle of operation: Batch mode

- Voltage: 220-230V

Vacuum coater is ideal for the application of salt and sugar solutions, enzyme, vitamin and anti-oxidants on water or oily basis as it ensures even distribution of small amounts of additives between the total product volume.

The price depends on the production capacity as well as the product being processed.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar