This washing equipment equipment excels in the thorough cleaning and grinding of fruits or vegetables.

The process begins as the loaded product is immersed in water. A lift conveyor then transports it out of the water, where high-pressure water ensures effective cleaning before moving to the next processing stage. The product undergoes additional cleaning using clear water on the conveyor.

This brush washer is specifically designed for production lines, offering flexibility with its adjustable conveyor speed. The incorporation of a specialized brush system ensures both efficient and gentle cleaning. The grinder at the end plays a crucial role in transforming the cleaned fruits or vegetables into a ready fruit mass or pulp, facilitating seamless integration into your production line.

- Cleaning of fruits or vegetables

- Simultaneous transfer and grinding

- Effective cleaning with high-pressure nozzles

- Mobile unit for enhanced flexibility

- Adjustable belt speed for optimal performance

- Productivity: 2000 kg/h 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

You might also like

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Dimensions: 2000x1230x1600

Volume: 150 l

Performance: up to 3000 kg/hour

Price on request.

- Productivity: do 3000 kg

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 150l

- Voltage: 380-400V

- Dimensions, mm: 2000x1230x1600

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

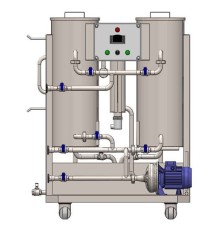

CIP-102 consists of two main tanks for alkaline and acid solution and one vessel used for neutralization of solutions.

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 100l

- Voltage: 380-400V

The destoner lift machine is designed for pre-washing and transporting root vegetables such as potatoes, carrots, beets, and other similar vegetables. After rinsing, the auger destoner separates floating particles like leaves and stems in the receiving hopper, while the product is conveyed up to the discharge height using a screw lift.

- Allows you to separate stones, leaves from root vegetables

- Pre-washing of root vegetable crops

- Two functions in one unit: washing and transporting

- Spacious hopper/tub for loading the product

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

Dimensions: 2000x1230x1600

Volume: 150 l

Performance: up to 3000 kg/hour

Price on request.

- Productivity: do 3000 kg

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 150l

- Voltage: 380-400V

- Dimensions, mm: 2000x1230x1600

Clean-in-place (CIP) is a method of cleaning and disinfecting the internal surfaces of pipes, containers, water tanks as well as industrial equipment, filters, related fittings and other accessories without the need for disassembly.

- Material: Stainless steel

- Volume: 2x50 l/ 2x100 l/

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

- Material: Stainless steel

- Engine power, kW: 0,75

- Voltage: 380-400V

- Productivity: 300 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Volume: 200l

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Wheat washer, huller and separator is used for the preparation of grain for milling. Price depends on your production capacity.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine