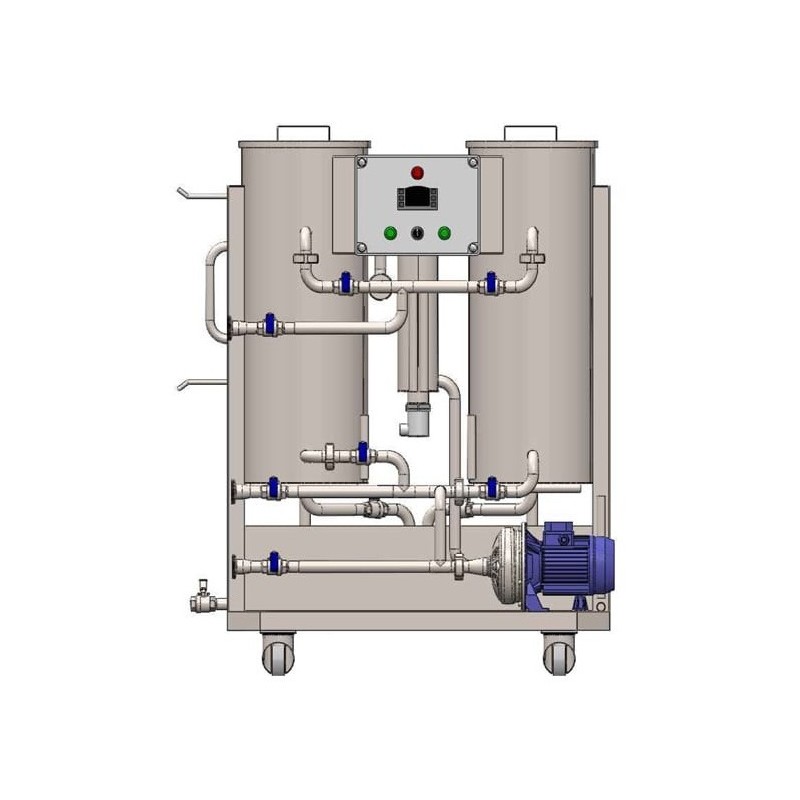

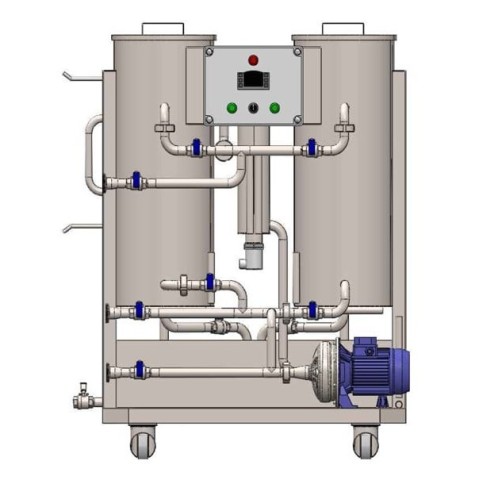

Cleaning and disinfection station CIP 102 - 2├Ś100 liters

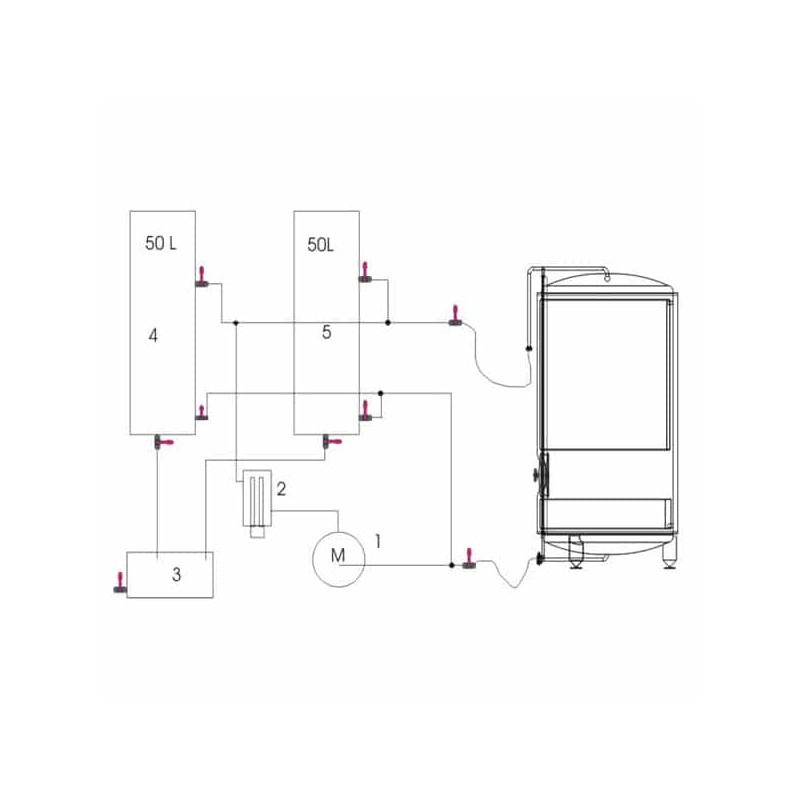

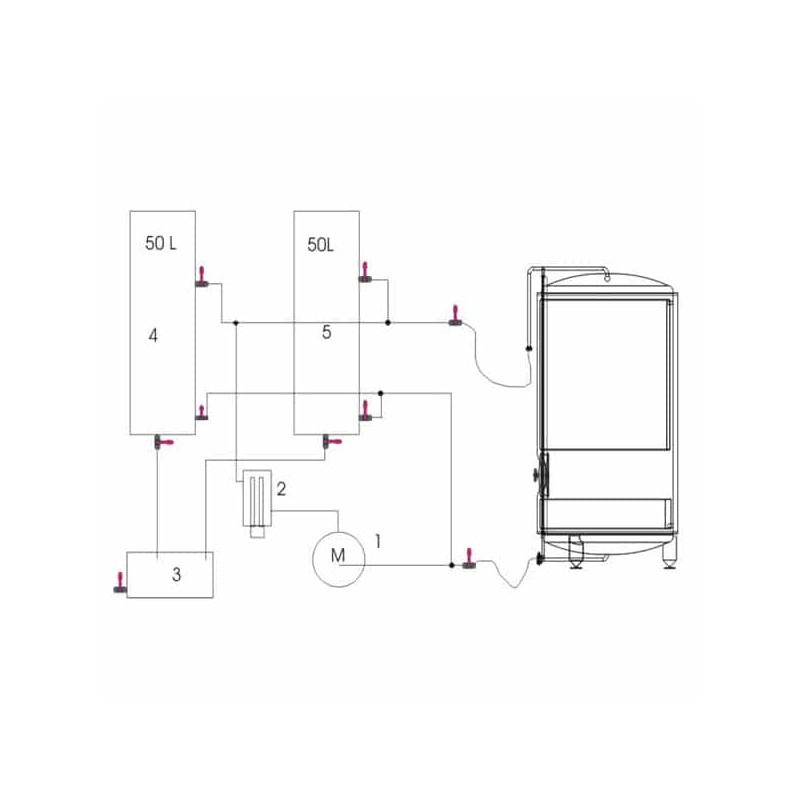

CIP-102 consists of two main tanks for alkaline and acid solution and one vessel used for neutralization of solutions.

CIP-102 is a mobile┬Ācleaning and sterilization unit for vessels and pipelines.

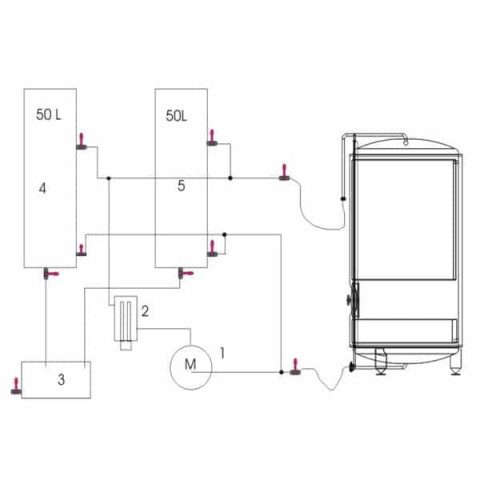

It is a complete system for breweries and other food processing industries. CIP equipment heats and circulates alkaline and acid solutions using a pumping system, hoses and a sanitary shower that sprays sanitary chemical solutions onto the internal walls of the sanitized tank. The device consists of two separate tanks with a nominal volume of 100 liters and one neutralization tank (53 liters), one centrifugal pump, electric control panel, manual valves, as well as all installation pipes. Digital temperature control in the range of 0-80┬░C. This type of CIP station is recommended for the cleaning and disinfection of fermentation tanks, storage tanks, water tanks from 0 to 4000 liters, as well as all pipelines and other objects that come into contact with drinks or food products.

Vessel functions:

- Alkaline vessel for alkaline cleaning - sanitation of all brewing equipment

- Vessel for acid cleaning of all brewery equipment

- Neutralizing vessel for neutralizing acidic and alkaline solutions before they are discharged into the sewer

The CIP-102 equipment is mounted on a rigid frame with fixed wheels. The material used is stainless steel 1.4301 (AISI 304) or 1.4404 (AISI 316) according to the option chosen. Containers (vessels) are not isolated. Pump internals and heating chambers are made of AISI 316 stainless steel. Pipes, fittings, frame and tanks are made of AISI 304 stainless steel.

The principle of the cleaning and disinfection process is based on the circulation of an alkaline or acidic solution through a sanitary shower, spraying it onto the walls of the vessel and into its space. It also features an instantaneous heater with digital temperature control ranging from 0┬░C to 80┬░C.

CIP-102 consists of two main tanks for alkaline and acid solution and one vessel used for neutralization of solutions. The circulation of sanitary solutions is provided by a pump and a system of connecting hoses.

Description of the sanitization cycle

The sanitation cycle usually consists of the following steps:

- Pre-rinsing - washing the production equipment with cold or hot water.

- Cleaning - cleaning of production equipment using recycled hot water.

- Rinsing - thorough rinsing of production equipment with cold or hot water.

- Chemical disinfection (sanitary) - washing equipment with an alkaline and then an acid disinfectant solution of the required concentration.

- Rinsing - thorough rinsing of production equipment with cold or hot water.

- Neutralization - performed after completing several cycles of cleaning and disinfection - mixing an alkaline and then an acidic disinfectant solution to achieve a neutral pH of the solution and drain them into the sewer.

Options:

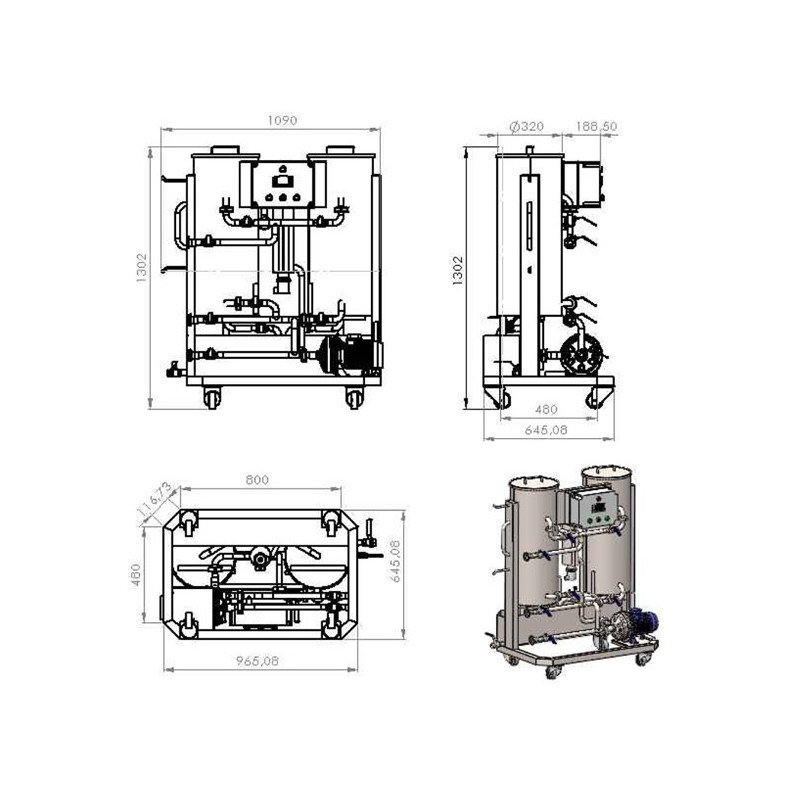

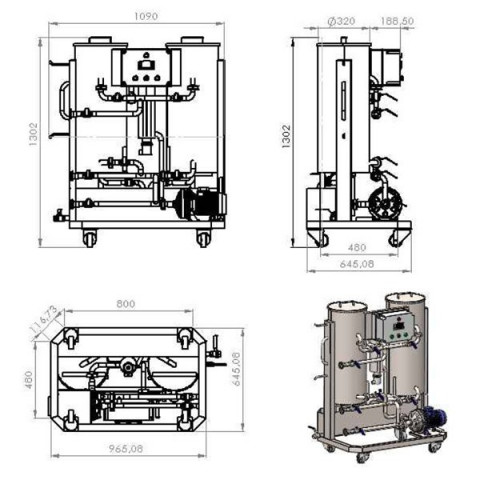

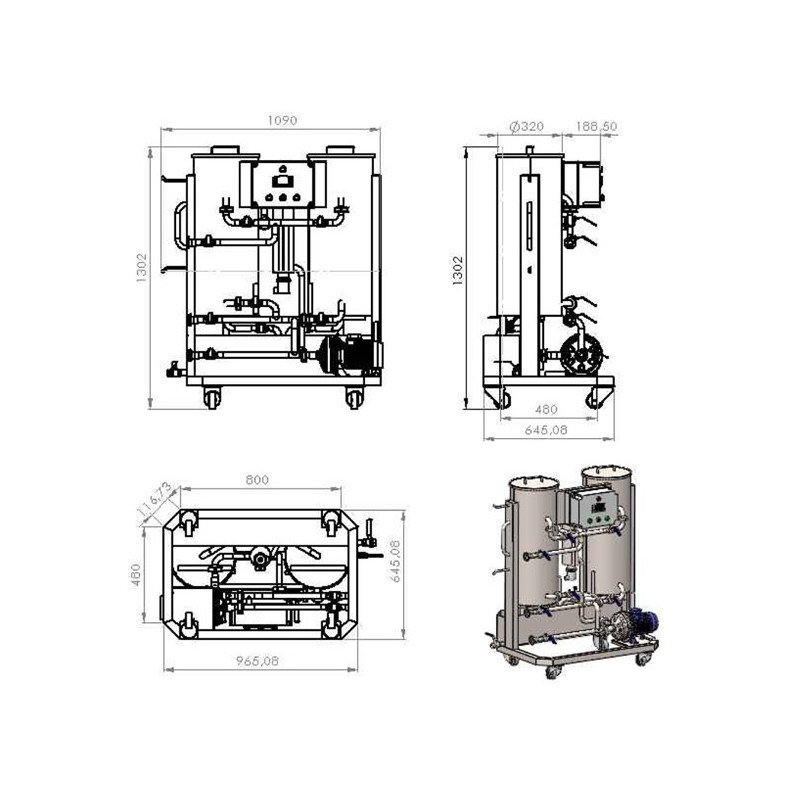

- Width 1,426 mm

- Height 1550 mm

- Depth 810 mm

- NAOH container 100 l

- Container with H2SO4 100 l

- Boiler 12 l

- Heating elements 2x 2000 W

- Neutralization vessel 53 l

- Distribution pipe DN 32

- Connection fittings (outlets / inlets) DN 32, 1.4301

- Centrifugal pump type EBARA CD / I 90 / 10 IE3, 0.75kW 90 l / min, 230V / 50Hz (AISI 316L)

- Electrical switchboard

- Main electrical connection 3 * 400V / 50Hz 16A

- Circuit breaker 230V 16A

- Digital regulator Dixel XR 10 D

- Heating contactor 230V 16A

- Engine starter 230V

- Sampler NTC 6 mm

- Cable 5x 2.5 5m

- Inlet (suction part) GG DN 32

- Outlet (exhaust part) GG DN 32

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 100l

- Voltage: 380-400V

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

- Material: Stainless steel

- Engine power, kW: 0,75

- Voltage: 380-400V

The destoner lift machine is designed for pre-washing and transporting root vegetables such as potatoes, carrots, beets, and other similar vegetables. After rinsing, the auger destoner separates floating particles like leaves and stems in the receiving hopper, while the product is conveyed up to the discharge height using a screw lift.

- Allows you to separate stones, leaves from root vegetables

- Pre-washing of root vegetable crops

- Two functions in one unit: washing and transporting

- Spacious hopper/tub for loading the product

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

Wheat washer, huller and separator is used for the preparation of grain for milling. Price depends on your production capacity.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

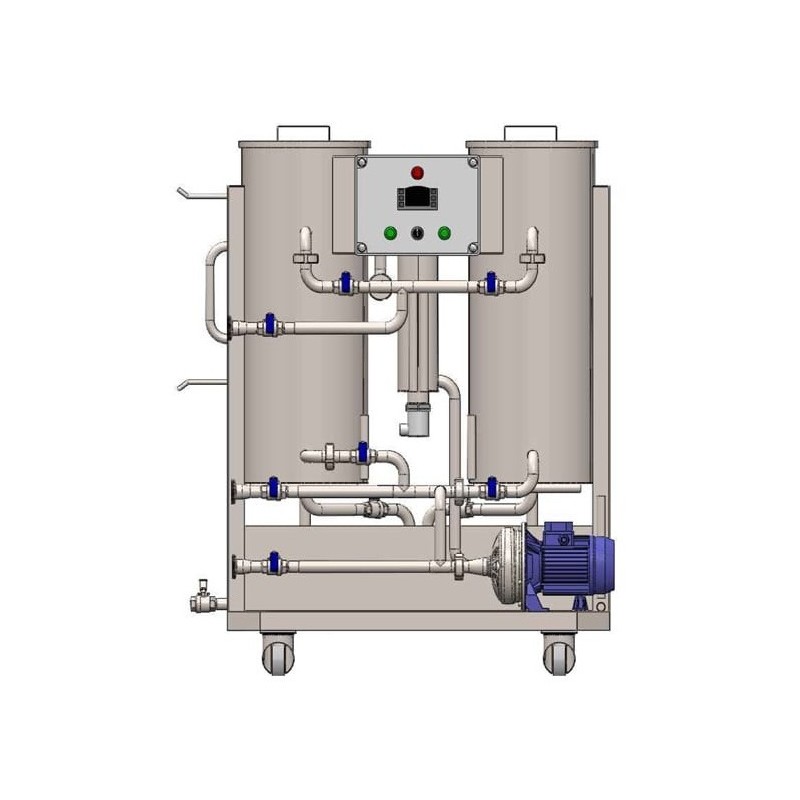

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

Bubble washer for gentle washing and cleaning of fruits and berries, for example peaches, cherries, strawberries and other raw fruits prior to their further processing.┬Ā

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 600 mm/ 800 mm/ 1000 mm

Improve the cleaning process with the CIP-53, a mobile station designed for thorough sterilization and sanitation of vessels and pipelines. Ideal for breweries and the food industry, this comprehensive system with three 50 or 100 liter tanks ensures efficient cleaning of fermentation and storage tanks, offers digital temperature control and neutralization.

- Material: Stainless steel

- Voltage: 380-400V

This machine allows washing and sterile rinsing with dry steam of cans and cups before filling them with product.

- Productivity: 6000 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

- Material: Stainless steel

CIP station CIP-101 With a usable capacity of 1├Ś100 liters, it is used for cleaning, sanitizing and sterilizing vessels and pipes in a brewery. This type of CIP station is recommended for cleaning and sanitizing tanks from 0 to 4000 liters.

- Material: Stainless steel

- Country of origin: EU

Compact universal washing and spin-drying unit designed for gentle and effective cleaning of fruits and vegetables. The system combines adjustable whirlpool washing with centrifugal drying, allowing efficient removal of soil, dust, and water in just a few minutes. Constructed entirely from food-grade stainless steel, it ensures hygienic operation and easy cleaning. Ideal for restaurants, hotels, catering kitchens, and small food processors.

- Efficient combined washing and drying process - total cycle under 5 minutes

- Adjustable washing intensity for delicate or firm products

- Stainless steel perforated drum for thorough cleaning and durability

- Integrated spin dryer for quick water removal and extended product shelf life

- Compact, easy-to-clean design with low water and energy consumption

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V

The container washer for canned food is a specialized washing system designed to thoroughly clean containers used for canning food products, ensuring hygiene and sanitation standards are met within your food processing facility.

This equipment model has been discontinued from serial production and is available only as a custom project upon request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia