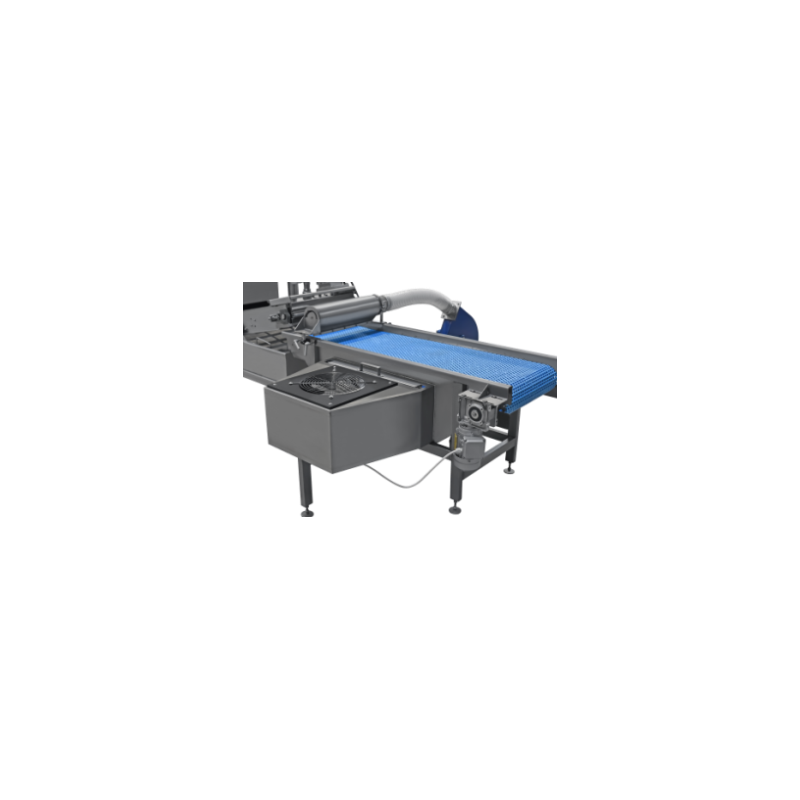

Air cooling conveyor CAC O 500/1700

An air cooling conveyor is a system that uses moving belts and airflow to cool down products as they are transported along the conveyor line.

For additional information or a price quote, send us a request.

The CAC series air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching by blowing air at ambient temperature.

Normit CAC refrigeration conveyors effectively reduce the temperature of the product (in most cases in a few seconds), thus stopping their cooking. The product is cooled to a temperature suitable for packaging.

It is intended for pre-cooling after cooking or frying vegetables and fruits, meat, fish and seafood and other products in three-packs or without.

Examples of applications:

- Nuggets

- Biscuits and chips

- Meat patties

- Blanched dried fruit

- And other

The design of the cooling conveyors ensures optimal air distribution over the entire surface of the conveyor belt. A high-performance industrial fan with power regulation is located in the lower part of the conveyor which is part of the system. With the help of a frequency converter, it is possible to regulate the belt speed and thus influence the cooling time.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 500 mm

You might also like

The inspection conveyor is designed for inspection and manual removal of unsuitable pieces of root vegetables, fruits and berries.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

Air cooling conveyor with MULTI AIR KNIFE is a system for┬Ā intensive┬Āremoving excess water or oil and preliminary cooling.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

It is intended for pre-cooling after cooking or frying vegetables and fruit, meat, fish and seafood and other products.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product as well as size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

The new line of NDJ refrigeration units is suitable as a cooling source for industrial applications operating with a closed coolant circuit. Efficient and reliable flow cooling of liquids

- Principle of operation: Continuous mode

- Country of origin: EU

Lowering the temperature and humidity protects the product even without chemical treatment. The device is also used for continuous air cooling after heat treatment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

Heating: electric and steam - combination

- Material: Stainless steel

- Principle of operation: Continuous mode

Fixed cooling unit wit different capacities from 67 kW up to 226 kW. Unit are solid and ensure long-life base operation.

- Country of origin: EU

The Milk Cooler has a simple design, which allows for easy and safe operation. it meets the requirements of all dairy production facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 200l/ 300l

- Voltage: 380-400V

The cooling units have a compact design. They are space-saving and easy to assemble. The chiller in standard version can work at water outlet temperatures from +10┬░C to +25┬░C.

For more information, send us an email to sales@normit.com┬Ā

- Volume: 18 l/ 30l

- Voltage: 220-230V

It is intended for pre-cooling after cooking or frying vegetables and fruit, meat, fish and seafood and other products.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

The cooling tank is designed for storing milk and other beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

The vacuum bread cooler is well-suited for application in small bakeries or as a laboratory unit in industrial enterprises. This enables the post-baking of bread under vacuum conditions, influencing both its shape and structure.

- Built-in deep vacuum system

- Built-in vapor removal and condensation system

- Built-in refrigeration system

- The chamber is designed for 3 gastro containers size GN 1/1, or pallets: 400x600/530x325 mm

- Compact and mobile installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 130l

- Voltage: 380-400V

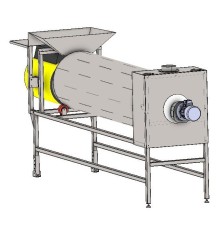

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

This air cooler and heater is multifunctional. It can be used as air cooler, heater. The compact and lightweight air cooler / heater contains. 4 caster wheels make it easy to move the unit.

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

The vacuum diffusion cooling unit is a multifunctional device not only for vegan processors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

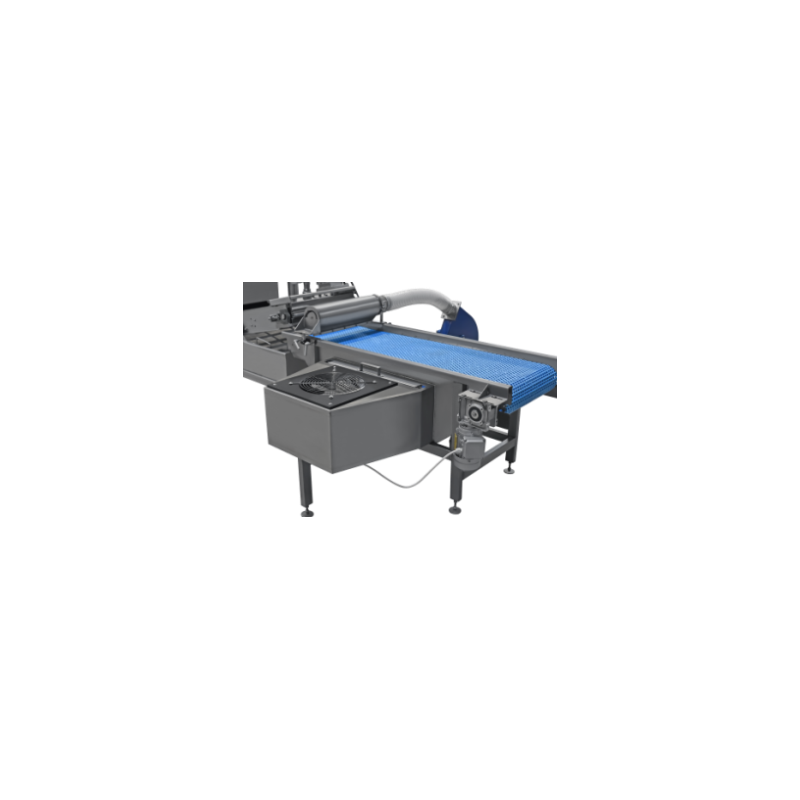

CAC Air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Voltage: 380-400V