0.75 kW Frequency converter with IP65

A frequency converter is an electrical device that adjusts the frequency of an input power source to control the speed and torque of electric motors, commonly used in industrial applications like pumps, fans, and conveyor systems.

- Power: 0.75 kW

- Input Voltage: 1 phase, 230 V, 50/60 Hz

- Rated Output Current: 4.5 A

- Output Frequency: 0 to 999.9 Hz

- Protection Rating: IP65

A frequency converter is used to adjust the input power source to control the speed and torque of electric motors in industrial applications.

The 0.75 kW frequency converter is engineered for robust performance in industrial environments, featuring IP65 dust and water protection. It is designed to regulate the speed of electric motors in applications such as pumps, mixers and conveyors.

Control and operation

This frequency converter can be controlled externally or directly via its user-friendly panel. Starting the inverter is done simply by pressing the START button, while speed adjustments can be made using the built-in knob for fine-tuning motor performance.

Key features

- Torque Enhancement: Increases motor torque by up to 20% for improved performance.

- Safety Function: EMS safety function allows for an immediate stop of the motor when needed.

- Protection Options: Connects to PTC protection or thermal contacts for additional safety measures.

- Built-in Functionality: Includes PID control, PLC, AVR, and two counters for versatile applications.

- EMC Compliance: Integrated EMC filter (C1/C2) ensures compliance with industry standards.

- Communication Interface: Standard RS 485 MODBUS physical interface for seamless integration into existing systems.

Installation

The frequency converter is supplied with a pre-connected power cable and output cable, facilitating straightforward installation and setup.

Key specifications

| Rated Output Power | 0,75 kW |

| Rated Input Current | 7,2 A |

| Rated Output Current | 4,5 A |

| Recommended Motor Power | 0,75 kW |

| Input Voltage 50/60Hz | 1 phase 1├Ś230 V |

| Motor Power | 0,75 kW |

| Recommended Cable Cross-Section | 2,5 mm┬▓ |

| Recommended Circuit Breaker | 16 A |

Power supply voltage

| Rated voltage | 1 Phase: 1x 230 V AC | 3 Phase: 3x 400 V AC |

| Frequency 50/60 Hz | Type: 2S for single-phase | Type: 4T for three-phase |

| Voltage range | 230 V: 170 V to 240 V | 400 V: 330 V to 440 V |

Output

| Voltage range | 3 x 230 V: 0 to 230 V | 3 x 400 V: 0 to 400 V |

| Frequency range | 0.10 to 999.9 Hz | 0.10 to 999.9 Hz |

- Type of the equipment: Optional equipment

- Voltage: 380-400V

You might also like

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

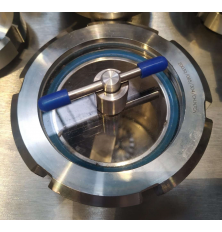

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Contact pressure gauge with a Bourdon tube, and a bottom connection.

- Type of the equipment: Optional equipment

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

Hygienic linear internal stainless steel drainage system for food production, professional kitchens, pharmaceutical enterprises, restaurants and many others. The drain trap has a stainless steel bath and a connection to the sewer.

- Grate with a frame

- The load class of the grate can withstand being runover with a car

- Fixed height drain

- Built-in grease trap (optional)

- Material: Stainless steel

- Country of origin: Slovakia

Designed for the demanding requirements of the beer and beverage processing industry, this pressure suction food hose offers exceptional safety, durability, and compliance with international food standards. It is ideal for the transportation of high-quality raw, pasteurized, and organic beer, as well as a variety of other beverages, including wine, soft drinks, and alcoholic drinks.

- Type of the equipment: Optional equipment

Stainless steel baskets for cooking kettles, autoclaves, pasteurizers.

- Material: Stainless steel

- Principle of operation: Batch mode

In the production of condensed milk, a refractometer is used to accurately determine the solids content of the product, which is essential for meeting production standards and ensuring compliance with legal regulations.

- Type of the equipment: Optional equipment

The sturdy mobile base for large pots, with a diameter ranging from 405 mm to 625 mm, is designed to support and easily transport our 50L, 100L and 150L cooking kettles.

- Made out of stainless steel

- Features casters with brakes on each wheel for secure handling

- Universal model for pots with diameters from 405 to 625 mm

- High load capacity - up to 200 kg

- Material: Stainless steel

- Type of the equipment: Optional equipment

The working surface is made out of food-grade stainless steel, on top of which the deep fryer can be installed. It is quipped with wheels for ease of movement.

- Material: Stainless steel

The durable single gas stove serves a versatile purpose, suitable for heating large cooking kettles. 7 kW.

- Heating: Gas

- Heating power, kW: 7

Compact and powerful gas stove with 3 rings designed for the connection to standard LPG cylinders. Ideal for heating large volumes of liquid, cooking soups or sauces in cooking kettles, and maintaining meal temperatures during preparation or service. The sturdy, open-frame design ensures excellent stability and high load capacity for everyday use in catering and food processing.

Protective decorative cover for colloid mill 132 (additional option)

- Material: Stainless steel

- Country of origin: Slovakia

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

Set of 4 height adjustable legs+/- 100 mm.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Additional option for the VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment