In-line refractometer for production lines

Various installation types are possible: in-line, directly into the product tank or via a bypass connector.

Simple and easy-to-use in-line refractometer, compact model.

Wide range with excellent accuracy

Measurements in a wide range from 0.00 to 80% Brix with an accuracy of ┬▒ 0.1%. Various versions with numerous special scales and intrinsically safe explosion-proof models are used.

Measurements are available at low and high temperatures

This refractometer is equipped with automatic temperature compensation (ATC) and supports a wide temperature range from 5Ōäā to 100. The contact surface can withstand temperatures up to 160 C, so the use of CIP or SIP cleaning is possible!

Flat Sample Cell Surface

By making the contact part completely flat, sample adhesion to the prism surface is minimized and hygiene is increased. The prism cell is re-polished in 1/100 mm increments during production to eliminate the possibility of minor irregularities between the prism surface and the cell.

Various special measurement scales available

Special scales are available for many common samples such as ethylene glycol, propylene glycol, urea, NMP, hydrogen peroxide solution, DMF, sodium hydroxide, ethyl alcohol (V/V), ethyl alcohol (W/W), IPA, wine and many others.

Technical specifications:

- Ranges: Brix: 0.0 - 80.0%. Temperature: -15 to 160 degrees C / 5 to 320 degrees. F

- Resolution - Brix: 0.01 to 0.1%

- Accuracy Brix: ┬▒0.1%

- Temperature: ┬▒1 deg. C / ┬▒1>’Š¤F

- Temperature compensation: 5 to 100 deg. C

- RS-232C output, DC 4 to 20mA

- Alarm output - open collector output for setting upper and lower limits (alarm output).

- Power supply: DC24V

- Type of the equipment: Optional equipment

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts

A frequency converter is an electrical device that adjusts the frequency of an input power source to control the speed and torque of electric motors, commonly used in industrial applications like pumps, fans, and conveyor systems.

- Power: 0.75 kW

- Input Voltage: 1 phase, 230 V, 50/60 Hz

- Rated Output Current: 4.5 A

- Output Frequency: 0 to 999.9 Hz

- Protection Rating: IP65

- Type of the equipment: Optional equipment

- Voltage: 380-400V

A hot oil filter for continuous industrial tabletop fryers allows you to quickly and effectively filter oil immediately after the frying process.

- Hot oil filtration - oil temperature up to 200 ┬░C.

- Optional filter material - paper, stainless steel

- Material: Stainless steel

- Country of origin: Slovakia

Contact pressure gauge with a Bourdon tube, and a bottom connection.

- Type of the equipment: Optional equipment

Supporting structure on wheels with locks (brakes), 2 swivel wheels, 2 swivel wheels with a brake.

- Type of the equipment: Optional equipment

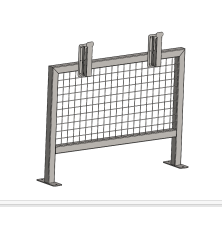

This rack is typically used as car mat holders at car washes. It can also serve as a universal stand for use in other enterprises.

- Material: Stainless steel

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

Additional option to VMG laboratory vacuum homogenizer 20/50.

- Material: Stainless steel

- Type of the equipment: Optional equipment

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

A large three-section basket for vacuum fryers, cooking kettles and other batch processing equipment.

- Material: Stainless steel

- Type of the equipment: Optional equipment

A thermometer is a precision tool used to measure product temperature in food processing, ensuring accurate control during cooking, mixing, and other food production processes. It helps to maintain consistency, optimize processing conditions, and meet safety standards in industrial food processing equipment like cooking kettles, blanchers and fryers.

- Material: Stainless steel

- Type of the equipment: Optional equipment

The sturdy mobile base for large pots, with a diameter ranging from 405 mm to 625 mm, is designed to support and easily transport our 50L, 100L and 150L cooking kettles.

- Made out of stainless steel

- Features casters with brakes on each wheel for secure handling

- Universal model for pots with diameters from 405 to 625 mm

- High load capacity - up to 200 kg

- Material: Stainless steel

- Type of the equipment: Optional equipment

Designed for the demanding requirements of the beer and beverage processing industry, this pressure suction food hose offers exceptional safety, durability, and compliance with international food standards. It is ideal for the transportation of high-quality raw, pasteurized, and organic beer, as well as a variety of other beverages, including wine, soft drinks, and alcoholic drinks.

- Type of the equipment: Optional equipment

Within seconds, the device measures the refractive index of the sample and converts it to % of solids using the concentration unit.

The refractometer is ready for use after a simple user calibration with deionized or distilled water.

Industrial refractometers are used to measure the concentration level of liquids in a continuous flow across various industries, applications, and industrial setups. They provide real-time measurement data, ensuring precise process control and maintaining the desired concentration of liquids. This enables industrial automation by eliminating the need for manual sampling and adjustments, allowing for consistent and accurate production.

- Type of the equipment: Optional equipment