Refractometer for condensed milk production

In the production of condensed milk, a refractometer is used to accurately determine the solids content of the product, which is essential for meeting production standards and ensuring compliance with legal regulations.

Sweetened condensed milk is produced by evaporating milk to reduce its water content and adding a sweetener, which can be sucrose, dextrose, or any other natural sugar.

This product was originally invented as a method of preserving milk. The sugar content in sweetened condensed milk increases the osmotic pressure to a level that eliminates most microorganisms.

Sugar is added either as a dry solid before evaporation or as a syrup during the process. Precise control of the added sugar amount is crucial, as the shelf life of the milk depends on maintaining a sufficiently high osmotic pressure. The sugar content in milk typically ranges from 62.5% to 64.5%.

A refractometer is used to standardize the product, ensuring the exact solids content required to meet legal standards. Accurate TDS (Total Dissolved Solids) measurements in fresh milk also help determine the precise amount of sugar that should be added before or during the evaporation stage.

Refractometer readings taken after evaporation can be used to fine-tune the evaporators and achieve the desired milk concentration.

If the production process includes a homogenization stage, a refractometer can also be installed afterward. It detects fat globules when their size is smaller than 6 ┬Ąm, a threshold that can be reached by adjusting the homogenizer pressure. The recommended primary homogenizer pressure is P1 = 26 MPa (260 bar).

The refractometer can be calibrated to display measurements in either Brix or Total Dissolved Solids (TDS), depending on the factoryŌĆÖs preference. Additionally, it features Ethernet and 4-20 mA output signals, which enable real-time process control.

Refractive index (nD): 1.3200 ŌĆō 1.5300 (corresponding to 0ŌĆō100 Brix).

- Type of the equipment: Optional equipment

Additional option to VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

Stainless steel baskets for cooking kettles, autoclaves, pasteurizers.

- Material: Stainless steel

- Principle of operation: Batch mode

Compact and powerful gas stove with 3 rings designed for the connection to standard LPG cylinders. Ideal for heating large volumes of liquid, cooking soups or sauces in cooking kettles, and maintaining meal temperatures during preparation or service. The sturdy, open-frame design ensures excellent stability and high load capacity for everyday use in catering and food processing.

Set of 4 height adjustable legs+/- 100 mm.

- Material: Stainless steel

- Type of the equipment: Optional equipment

A large three-section basket for vacuum fryers, cooking kettles and other batch processing equipment.

- Material: Stainless steel

- Type of the equipment: Optional equipment

The oil-free four-cylinder piston compressor is the ideal solution for those who value both performance and silence.

- Equipped with two twin-piston units with separate engines

- Four air filters

- Mechanical pressure switch

- Quiet operation (at least 25% quieter than traditional compressors)

- Carrying handle and mobile wheel support

- Principle of operation: Continuous mode

- Total power, kW: 1,5

- Voltage: 220-230V

Stainless steel mesh baskets designed for use with our cooking kettles, blanchers, evaporators, fryers and pasteurizers. Ideal for thermal processing, subsequent draining, and unloading of products such as vegetables, fruits, pasta, meat, or jars after cooking, blanching, or pasteurization.

Available in multiple sizes ranging from 30├Ś30 to 40├Ś40 cm.

Protective decorative cover for colloid mill 132 (additional option)

- Material: Stainless steel

- Country of origin: Slovakia

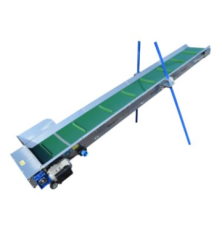

Variable belt conveyor with wide use not only in the food industry. The length of the conveyor can be selected from 2 to 6 m. The width of the belt is 200 and 400 mm.

- Engine power, kW: 0,75

- Principle of operation: Continuous mode

Analogue refractometers offer an efficient, accurate, and easy-to-use solution for measuring Brix levels and ensuring product quality in the food industry.

- Type of the equipment: Optional equipment

Stand (support structure) for colloid mill machine - additional option for the colloid mill 132

- Type of the equipment: Optional equipment

Designed for the demanding requirements of the beer and beverage processing industry, this pressure suction food hose offers exceptional safety, durability, and compliance with international food standards. It is ideal for the transportation of high-quality raw, pasteurized, and organic beer, as well as a variety of other beverages, including wine, soft drinks, and alcoholic drinks.

- Type of the equipment: Optional equipment

A thermometer is a precision tool used to measure product temperature in food processing, ensuring accurate control during cooking, mixing, and other food production processes. It helps to maintain consistency, optimize processing conditions, and meet safety standards in industrial food processing equipment like cooking kettles, blanchers and fryers.

- Material: Stainless steel

- Type of the equipment: Optional equipment

The sturdy mobile base for large pots, with a diameter ranging from 405 mm to 625 mm, is designed to support and easily transport our 50L, 100L and 150L cooking kettles.

- Made out of stainless steel

- Features casters with brakes on each wheel for secure handling

- Universal model for pots with diameters from 405 to 625 mm

- High load capacity - up to 200 kg

- Material: Stainless steel

- Type of the equipment: Optional equipment