Digital Brix Refractometer

Within seconds, the device measures the refractive index of the sample and converts it to % of solids using the concentration unit.

The refractometer is ready for use after a simple user calibration with deionized or distilled water.

Refractometer for determining the proportion of dry substances in the product.

The digital refractometer is temperature compensated, with a BRIX range of 0 to 85 percent and an accuracy of +/- 0.2 percent. It is easy to use, with simple two-button operation and a fast response time of less than 2 seconds. Maintenance is straightforward, thanks to a sealed flint glass prism and a stainless steel tank that are easy to clean.

Ideal for winemakers, brewers, fruit and vegetable processing, maple syrup producers and other food manufacturers.

Benefits

- Fast and accurate results with a digital two-level LCD display. Easy measurement with just 2-3 drops of sample and results in less than 2 seconds.

- Simple one-point calibration using distilled or deionized water.

- Easy-to-clean stainless steel tank with IP65 protection as âdust-proofâ and protected against water jets.

- Battery level indicator with automatic shut-off

Main features:

- Two-level LCD display

- Easy to set up and save data

- Low battery indicator

- Automatic shut-off after 3 minutes of inactivity.

- Measuring range: 0 to 85%, 0 to 80 °C / 32 to 176 °F

- Sensitivity: 0.1%, 0.1 °C / F

- Deviation: pH ± 0.2% sugar, ± 0.3 °C / 0.5 °F

- Light source: Yellow LED

- Measuring time: approx. 1.5 s

- Minimum measurable quantity 100 µl

- Battery: 1 x 9 V AA, service life approx. 5000 measurements

- Dimensions: 268 x 122 x 118 mm

- Weight: 660 g

- Automatic temperature compensation 10-40 °C

A thermometer is a precision tool used to measure product temperature in food processing, ensuring accurate control during cooking, mixing, and other food production processes. It helps to maintain consistency, optimize processing conditions, and meet safety standards in industrial food processing equipment like cooking kettles, blanchers and fryers.

- Material: Stainless steel

- Type of the equipment: Optional equipment

The IBC container insulation cover is designed for use in ice water stations with IBC containers to maintain the cold coolant at a set temperature.

- Allows you to reduce energy costs of the refrigeration machine - chiller

- Protects from short-term fluctuations in ambient temperature, reflects sunlight (up to 97%)

- The cover is easy to install, with valve holes are installed with hook-and-loop fasteners (Velcro)

- Type of the equipment: Optional equipment

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

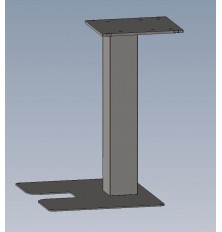

Stand (support structure) for colloid mill machine - additional option for the colloid mill 132

- Type of the equipment: Optional equipment

Stainless steel mesh baskets designed for use with our cooking kettles, blanchers, evaporators, fryers and pasteurizers. Ideal for thermal processing, subsequent draining, and unloading of products such as vegetables, fruits, pasta, meat, or jars after cooking, blanching, or pasteurization.

Available in multiple sizes ranging from 30Ã30 to 40Ã40 cm.

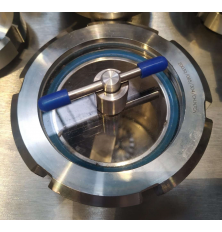

Industrial refractometers are used to measure the concentration level of liquids in a continuous flow across various industries, applications, and industrial setups. They provide real-time measurement data, ensuring precise process control and maintaining the desired concentration of liquids. This enables industrial automation by eliminating the need for manual sampling and adjustments, allowing for consistent and accurate production.

- Type of the equipment: Optional equipment

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Supporting structure on wheels with locks (brakes), 2 swivel wheels, 2 swivel wheels with a brake.

- Type of the equipment: Optional equipment

The set consists of 20 shelves from AISI304 stainless steel. Additional option for MAK DRYER 7-14.

- Material: Stainless steel

- Type of the equipment: Optional equipment

The working surface is made out of food-grade stainless steel, on top of which the deep fryer can be installed. It is quipped with wheels for ease of movement.

- Material: Stainless steel

Stainless steel baskets for cooking kettles, autoclaves, pasteurizers.

- Material: Stainless steel

- Principle of operation: Batch mode

Additional option for the VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

Hygienic linear internal stainless steel drainage system for food production, professional kitchens, pharmaceutical enterprises, restaurants and many others. The drain trap has a stainless steel bath and a connection to the sewer.

- Grate with a frame

- The load class of the grate can withstand being runover with a car

- Fixed height drain

- Built-in grease trap (optional)

- Material: Stainless steel

- Country of origin: Slovakia

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment