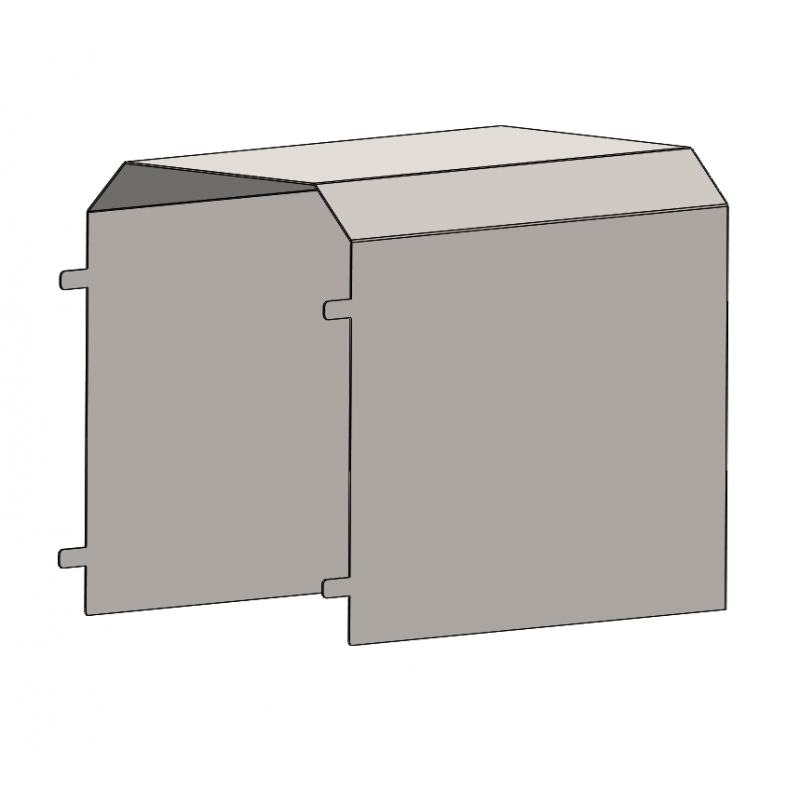

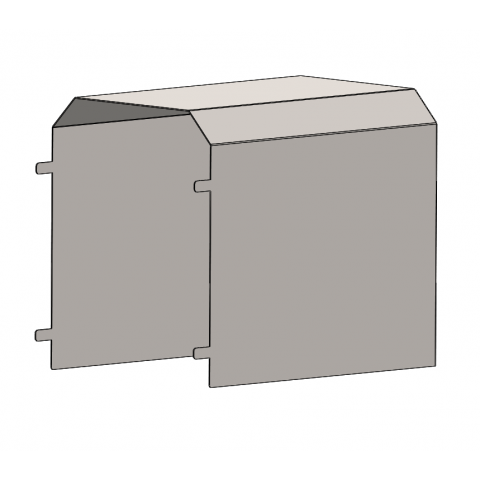

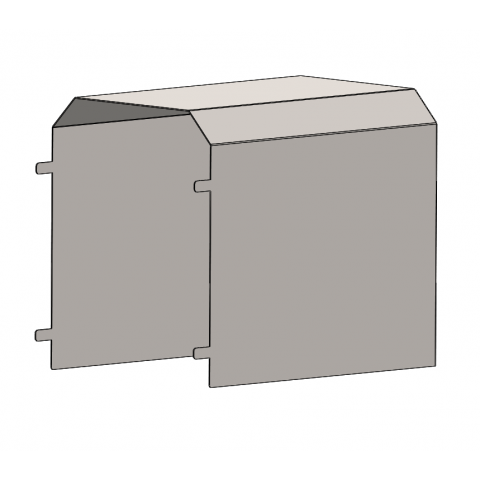

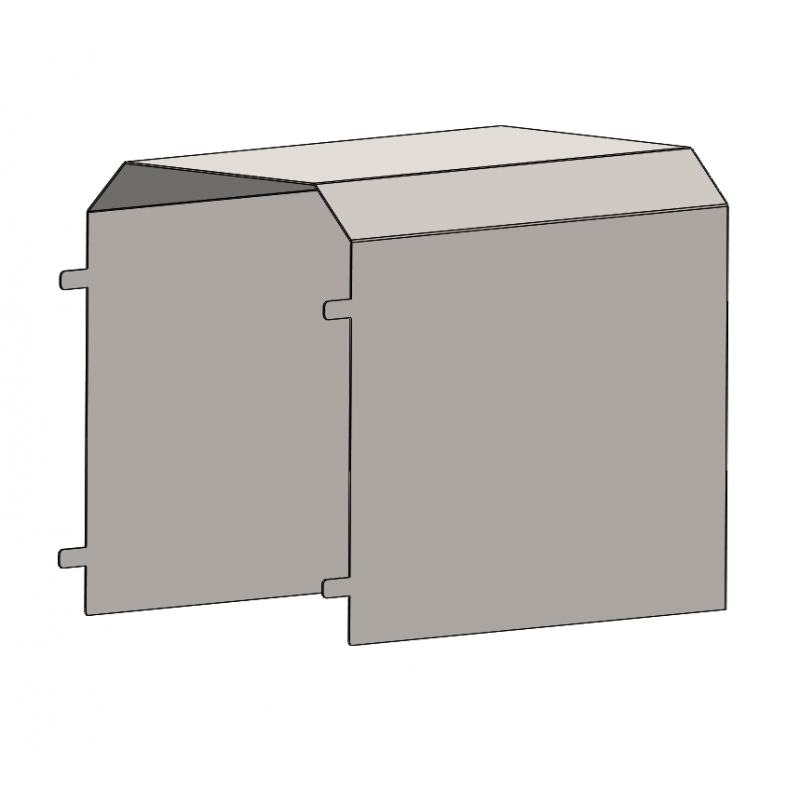

Protective decorative cover for the colloid mill 132

Protective decorative cover for colloid mill 132 (additional option)

- Material: Stainless steel

- Country of origin: Slovakia

You might also like

The colloid mill is used for continuous grinding of nuts, to obtain a finished nut paste of various viscosities with one pass through, without requiring additional processing or preparation!

- Simple and easy operation

- Three-point grinding adjustment

- Possibility of producing both creamy and crunch-type nut butters

- Compact design

- High performance

- Productivity: 180-240 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

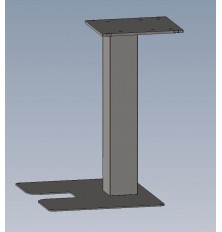

Stand (support structure) for colloid mill machine - additional option for the colloid mill 132

- Type of the equipment: Optional equipment

Designed for a load of up to 200 kg!

The 5 kW induction cooker is the best alternative to traditional electric and gas stoves. It reduces energy costs, improves safety, and minimizes air pollution, making it suitable for both stationary kitchens and mobile catering setups. Its compact design also makes it a practical choice for small kitchens where space and efficiency matter.

- 10-step power (500ŌĆō5000 W) or 10-step temperature (60ŌĆō280 ┬░C) control

- Connection - 230 Volt

- Compact dimensions: 410x500x200 mm

- Temperature range from 60 to 280 degrees

- Heating power, kW: 5

- Voltage: 220-230V

Additional option to VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment

The oil-free four-cylinder piston compressor is the ideal solution for those who value both performance and silence.

- Equipped with two twin-piston units with separate engines

- Four air filters

- Mechanical pressure switch

- Quiet operation (at least 25% quieter than traditional compressors)

- Carrying handle and mobile wheel support

- Principle of operation: Continuous mode

- Total power, kW: 1,5

- Voltage: 220-230V

Set of 4 height adjustable legs+/- 100 mm.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Rechargeable and portable, ideal for measuring sugar content in fruit juices and beverages, ergonomic design.

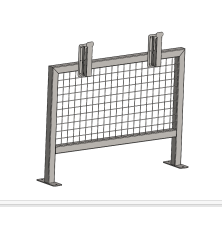

This rack is typically used as car mat holders at car washes. It can also serve as a universal stand for use in other enterprises.

- Material: Stainless steel

The IBC container insulation cover is designed for use in ice water stations with IBC containers to maintain the cold coolant at a set temperature.

- Allows you to reduce energy costs of the refrigeration machine - chiller

- Protects from short-term fluctuations in ambient temperature, reflects sunlight (up to 97%)

- The cover is easy to install, with valve holes are installed with hook-and-loop fasteners (Velcro)

- Type of the equipment: Optional equipment

The working surface is made out of food-grade stainless steel, on top of which the deep fryer can be installed. It is quipped with wheels for ease of movement.

- Material: Stainless steel

Various installation types are possible: in-line, directly into the product tank or via a bypass connector.

- Type of the equipment: Optional equipment

A hot oil filter for continuous industrial tabletop fryers allows you to quickly and effectively filter oil immediately after the frying process.

- Hot oil filtration - oil temperature up to 200 ┬░C.

- Optional filter material - paper, stainless steel

- Material: Stainless steel

- Country of origin: Slovakia

Supporting structure on wheels with locks (brakes), 2 swivel wheels, 2 swivel wheels with a brake.

- Type of the equipment: Optional equipment

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

Thermal insulation of the drying cabinet body to reduce heat loss during product drying. Additional option for the MAK DRYER 7-14.

- Type of the equipment: Optional equipment

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts

Hygienic linear internal stainless steel drainage system for food production, professional kitchens, pharmaceutical enterprises, restaurants and many others. The drain trap has a stainless steel bath and a connection to the sewer.

- Grate with a frame

- The load class of the grate can withstand being runover with a car

- Fixed height drain

- Built-in grease trap (optional)

- Material: Stainless steel

- Country of origin: Slovakia

The set consists of 20 shelves from AISI304 stainless steel.┬ĀAdditional option for MAK DRYER 7-14.

- Material: Stainless steel

- Type of the equipment: Optional equipment