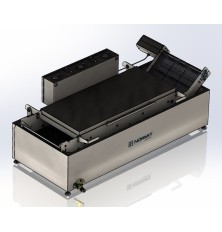

Continuous blancher ConF 600/3000

Excellent blancher and cooker for efficient handling of vegetables and other food products.

The continuous cooker and blancher ConF is an excellent machine used for food processing. It is made entirely out of stainless steel, including the electrical cabinet.

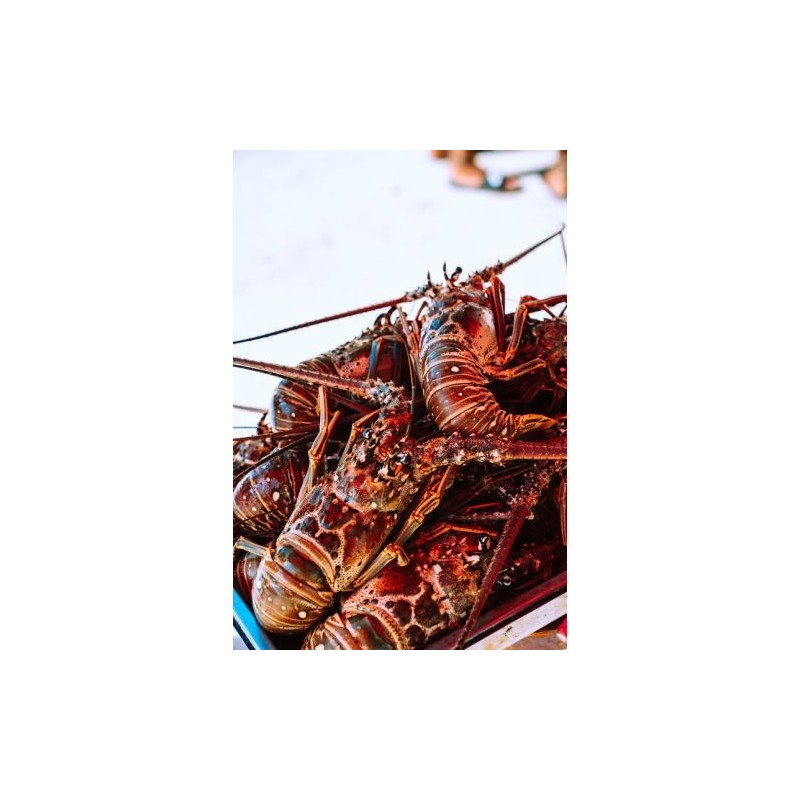

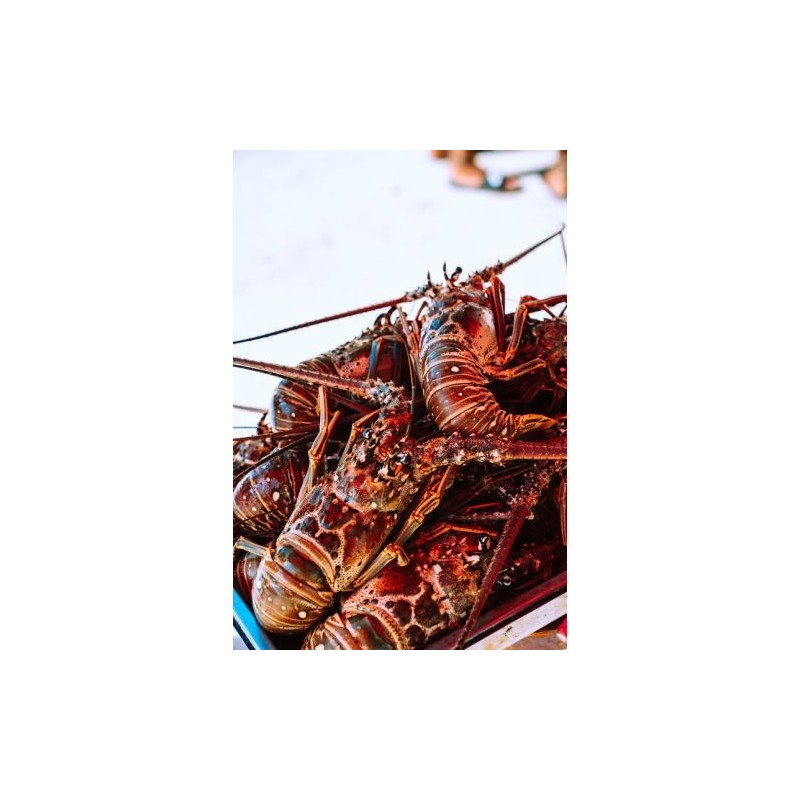

Products to cook:

- Fruits

- Vegetables

- Pasta

- Seafood

- Meat

- Fish

- Mushrooms

Features:

- Very simple control and cleaning.

- Option to load with dispenser, feed belt or by hand.

- Conveyor system with Teflon coated stainless steel for all parts in contact with the product.

- Thermally insulated.

- Electronic control of belt speed and liquid temperature.

- Lifting and transporting carriage

- Made entirely from stainless steel, including electrical cabinets

Technical data:

- Dimensions: 3300čģ600čģ1064 mm (LčģWčģH)

- Product unloading height: 926 mm

- Weight: 450 kg

- Liquid capacity = 300 liters

- Low energy consumption = 40 kW

- Electric current: 380/400 V

- Principle of operation: Continuous mode

- Working Area Width: 600 mm

- Voltage: 380-400V

The industrial planetary mixer is mainly used in the confectionary industry. Available in three different sizes: 120, 140 and 170 L.

- Engine power, kW: 5,5

- Voltage: 380-400V

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

A universal conveyor with a PVC belt with horizontal sections, a volumetric storage, adjustable in height and angle of inclination, which can easily be adapted to existing installations for lifting the product to a certain height. The conveyor has its own independent drive, the speed of which can be adjusted using an inverter (optional).

- Lightweight: the supporting structure of the conveyor is made out of aluminum profiles

- Hopper made out of food grade stainless steel

- Bearing frame on wheeled supports with position locks

- High sidewalls made out of stainless steel

- White PVC tape for transporting products with temperatures of up to 80 degrees

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Volume: 50l/

The vacuum bread cooler is well-suited for application in small bakeries or as a laboratory unit in industrial enterprises. This enables the post-baking of bread under vacuum conditions, influencing both its shape and structure.

- Built-in deep vacuum system

- Built-in vapor removal and condensation system

- Built-in refrigeration system

- The chamber is designed for 3 gastro containers size GN 1/1, or pallets: 400x600/530x325 mm

- Compact and mobile installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 130l

- Voltage: 380-400V

The conveyor is made out of strong and highly-resistant stainless steel. It is also additionally reinforced for reliability during operation.

- Material: Stainless steel

- Principle of operation: Continuous mode

The series of Continuous Fryers Pour Oil is the boom in the market of frying and roasting equipment. The new construction designed by our engineers, based on existing practical experience in the production and use of conveyor fryers, provides the best example of environmental friendliness.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

An adjustable electric donut fryer with a continuous conveyor system is specially designed for small confectionery shops, pastry production and catering establishments. It is capable of frying a variety of products similar to donuts.

- Material: Stainless steel

- Heating power, kW: 12

- Country of origin: Slovakia

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Planetary mixers are primarily used in the confectionary industry. Offered in three different capacities.

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 100l/ 150l/ 200l/ 250l/ 300l

A spiral mixer with a fixed bowl and an electronic control panel. Available in various different capacities.

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 120 l/ 160 l/ 200l/ 250 l

- Voltage: 380-400V

The screw conveyor with heating is a device designed for the transportation of material using a screw mechanism, while heat is applied to the product to facilitate easier transfer. This type of conveyor is often used to simplify the transfer of various bulk materials.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

An ideal solution that greatly facilitates and speeds up the work of the attendants, without having to lift and turn the bowl in order to transfer the dough to another dosing or portioning machine, for example, to another batcher or portioner.

- Material: Stainless steel

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Engine power, kW: 0,25

- Weight: 100

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU