Bratt pan - Commercial cooking boiler GHE

The GHE boiler can be used in butchery, smokestack, fruit preserving, etc. It is used for cooking soups, sauces, meat, pasta, dairy meals without the risk of burning, for stewing fish, vegetables, mushrooms, for heating frozen meals or semi-finished products.

The boiling pan consist of a stainless steel duplicator and a self-supporting frame.

The duplicator consists of a pressed top plate, a pressed tank bottom, an inner and an outer wall. Indirect heating is designed for fast cooking and maintaining the temperature.

Cooking with a duplicator ensures even heating, food does not burn through - cooking procedures are in accordance with ecological food processing. The contents of the cooking vessel are heated by the steam generated in the duplicator. The boiler's cooking vessel is square, thus enabling cooking, stewing and heating using vessels according to the Gastro-norm size range. (up to container dimensions 300 L)

The device is equipped with height-adjustable legs to compensate for uneven floors. The control panel of the device is very easy to use.

The boiler is equipped with a safety valve that protects it from excessive overpressure and at the same time ensures valve deaeration before the start of cooking and its re-aeration after cooking. A part of this valve is also a hand manometer, which allows at the same time checking the pressure in the duplicator.

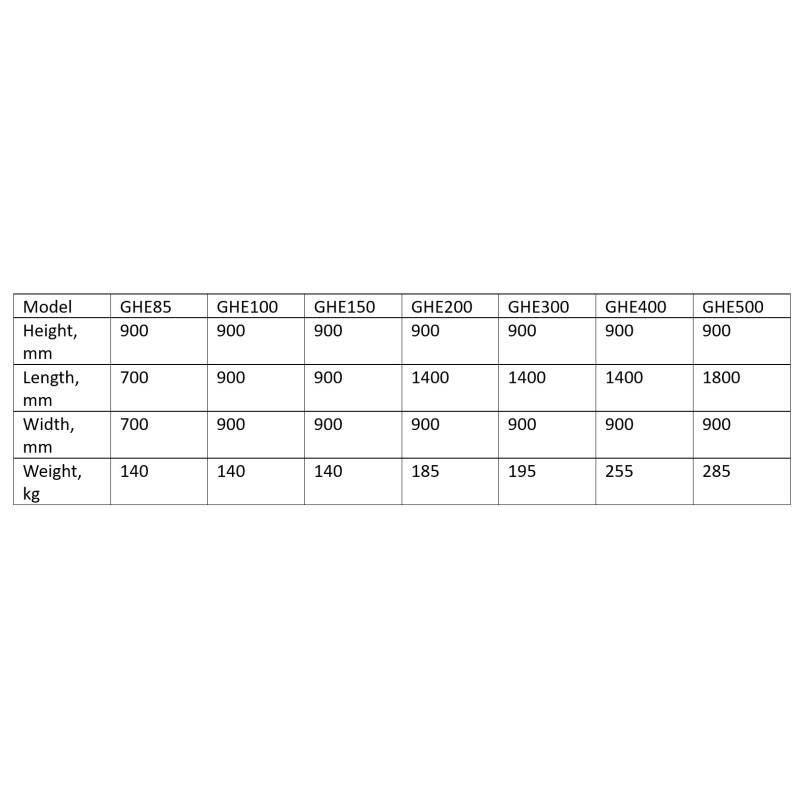

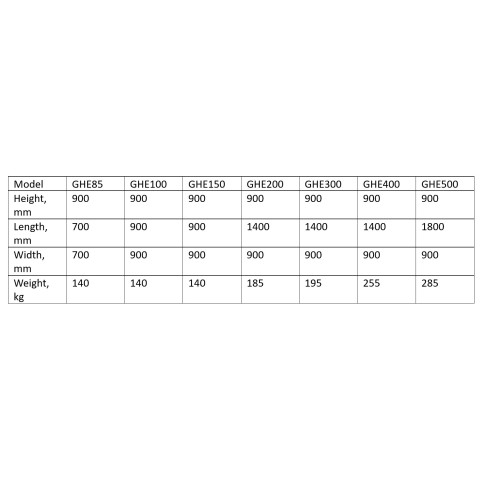

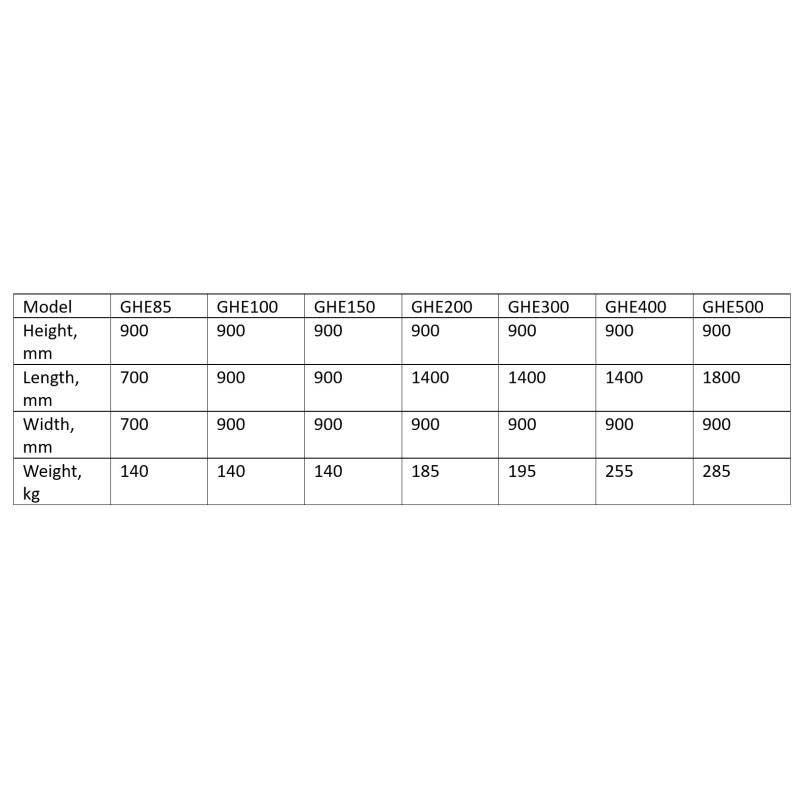

| Model | GHE 85 | GHE 100┬Ā | GHE 150 | GHE 200 | GHE 300 | GHE 400 | GHE 500 |

| Volume, L | 85 | 100 | 150 | 200 | 300 | 400 | 500 |

| External dimensions, mm | 700x700x900 | 900x900x900 | 900x900x900 | 1400x900x900 | 1400x900x900 | 1400x900x900 | 1800x900x900 |

| Weight, kg | 140 | 140 | 140 | 185 | 195 | 255 | 285 |

| 3 input position | 12 kW | 12 kW | 18 kW | 24 kW | 30 kW | 36 kW | 42 kW |

| heating time, minute | 60 | 60 | 60 | 60 | 60 | 90 | 70 |

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24/ 30/ 36/ 42

- Principle of operation: Batch mode

- Volume: 85l/ 100l/ 150l/ 200l/ 300l/ 400l/ 500l

Industrial kettle for cooking and stewing meat, vegetables, seafood, legumes, cereals under pressure up to 0.5 and temperatures up to 110 ┬░C bar.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 600 l

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as a┬Āvacuum evaporator, a┬Āvacuum cooking kettle, and a┬Āunit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

The brewery boiler comprises a two-pot-shaped assembly, in which the integrated frame is a built-in lauter tun, a mash tank, a whirlpool, a laboratory sink and a control panel.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1800l

Cooking kettle for making syrups, caramel, sugaring paste as well as processing and producing various thick and viscous products. Often used for dissolving sugar and producing various saturated and supersaturated solutions.

- Built-in heating with thermal oil up to 150 degrees Celsius

- Anchor frame stirrer for rapid dissolution

- Conical bottom design of the working container without dead zones

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The gas cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. This cooking equipment is not suitable for roasting or baking.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 80l/ 100l/ 150l/ 200l/ 300l

Universal cooking kettle for thick mixtures: it works on the principle of a water bath and can be used in confectionery shops, bakeries and other catering establishments. Offers a wide variety of models.

- Mechanical tilting system for unloading

- Safety grill for the mixer drive

- Built-in electric heating up to 150 degrees

- Mobile support structure on wheels

- Heating: Electricity

- Principle of operation: Batch mode

- Volume: 30l/ 60l/ 80l/ 120l

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The vacuum cooking and concentration unit is designed for concentrating products at low temperatures (about 60 degrees) in a reactor with a discharged environment to preserve the color, nutritional value and useful natural substances in present in food products. Evaporation and concentration units are often used when cooking jams, sauces, as well as fruit or vegetable concentrates. The vacuum concentrator allows you to boil and concentrate heat-sensitive products without damaging or destroying their structure or proteins, such as milk.

- Inclined design - allows for gravity mixing, which is 40% more efficient than usual

- Quick and 100% emptying of the tank thanks to the inclined design with the mixer on

- Heating/cooling jacket (duplicator) for the working tank and bottom

- High hygiene standard - the output valve is located at the lowest hydraulic point of the reactor

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 500l/ 875l

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

This premium cooking kettle is gas-fired and has a capacity of 120 liters. Ideal for preparing a wide variety of dishes.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 120l

- Working volume: 100