Milk cooling tank 4 milkings

Milk cooler tank designed for cooling milk and other dairy products. The tank is available in 13 different capacities, covering a range from 50 liters all the way up to 2,500 liters, capable of meeting the needs of all dairy & cheese production facilities. We offer 2 or 4 milking options. Prices are displayed for the milk cooling tank with 4 milking.

This chiller is designed for cooling milk.

The tank is a modern, energy-saving and robust design for cooling milk. The maximum amount of milk poured into the tank is half of its working volume. The milk cooling tank is available in 13 different capacities, covering a range from 50 liters to 2,500 liters, that meets the needs of all dairy units & cheese dairies.

Available option for extra charge: High precision (Ā±0,1%) weighting system with independent LCD screen

After cooling the milk, it is possible to add additional pre-cooled milk (up to 10 Ā° C) to avoid stirring the chilled and uncooled milk. This way the cooling takes place at the right time, so as to avoid both the development of bacteria and the increase of milk acidity (pH).

Milk cooling tank with a gear reduction motor

A special shaft with paddles and a gear reduction motor set to the appropriate RPM mixes the milk so as to ensure perfect homogenization of fats and uniform cooling of the entire quantity of milk without foaming.

The sophisticated design of these tanks ensures a number of advantages for the dairy unit, such as space saving, functional simplicity and easy transportation, installation, repair and maintenance. The cooling mechanisms and their capacities have been designed in order to meet the demands of both sheep and goat units and small cattle farming units.

Cooling tanks from 50L to 300L are mainly suitable for sheep and goat livestock units and can serve milk collection of 2 or 4 milkings. Tanks from 400L to 2,500L can serve small cow milking parlors and large sheep and goat milking parlors.

Milk cooling tanks are made of food grade materials and follow the European and US standards ISO5708 / EĪ13732 / 3A.

Fast and stable cooling and maximum energy saving are common characteristics of all models.

- Material: Stainless steel

- Principle of operation: Batch mode

You might also like

Pasteurizer, cheese boiler is designed for processing milk, yogurt, fruit juice or other liquids.Ā

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Volume: 200l/ 300l/ 500l

Vertical steam generators with horizontal pipes that take up a compact area. Price on request.Ā

- Material: Stainless steel

The atmospheric batch cooker model UniCook E or UniCook S, featuring a stirrer, is tailored to meet the diverse cooking needs of various food production businesses in industrial settings.

- Heating: Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 1000l

The Milk Cooler has a simple design, which allows for easy and safe operation. it meets the requirements of all dairy production facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 200l/ 300l

- Voltage: 380-400V

The water chiller CHWHE consists of a cooling unit in the upper part and a pump plus isolated water tank (made of stainless steel) in the lower section. We offer different capacities.

- Volume: 120 l/ 300l

- Voltage: 380-400V

The cooling tank is designed for storing milk and other beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

This air cooler and heater is multifunctional. It can be used as air cooler, heater. The compact and lightweight air cooler / heater contains. 4 caster wheels make it easy to move the unit.

The NWT PLUS chillers have a compact design. They take little space and are very easy to install and to start. The units are mobile on wheels. We offer different capacities.

- Heating: integrated

- Voltage: 380-400V

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

The IBC container insulation cover is designed for use in ice water stations with IBC containers to maintain the cold coolant at a set temperature.

- Allows you to reduce energy costs of the refrigeration machine - chiller

- Protects from short-term fluctuations in ambient temperature, reflects sunlight (up to 97%)

- The cover is easy to install, with valve holes are installed with hook-and-loop fasteners (Velcro)

- Type of the equipment: Optional equipment

The vacuum diffusion cooling unit is a multifunctional device not only for vegan processors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

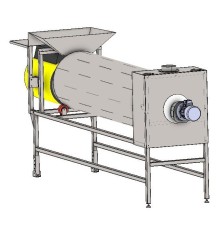

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

Lowering the temperature and humidity protects the product even without chemical treatment. The device is also used for continuous air cooling after heat treatment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

A chiller is a cooling machine that removes heat from a liquid through vapor compression and absorption in a cyclic manner.

- Principle of operation: Continuous mode

- Cooling performance l/h: 100 / 200 l/ 300

The Milk Cooler has a simple design, which allows for easy and safe operation. it meets the requirements of all dairy production facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 200l/ 300l

- Voltage: 380-400V

The new line of NDJ refrigeration units is suitable as a cooling source for industrial applications operating with a closed coolant circuit. Efficient and reliable flow cooling of liquids

- Principle of operation: Continuous mode

- Country of origin: EU

CAC Air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Voltage: 380-400V

An air cooling conveyor is a system that uses moving belts and airflow to cool down products as they are transported along the conveyor line.

For additional information or a price quote, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 500 mm