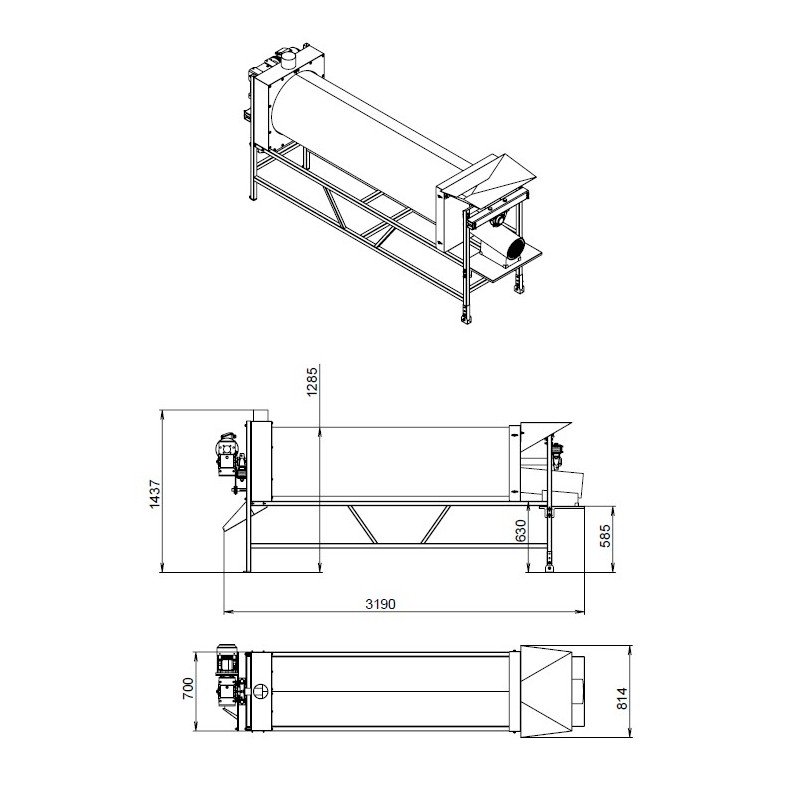

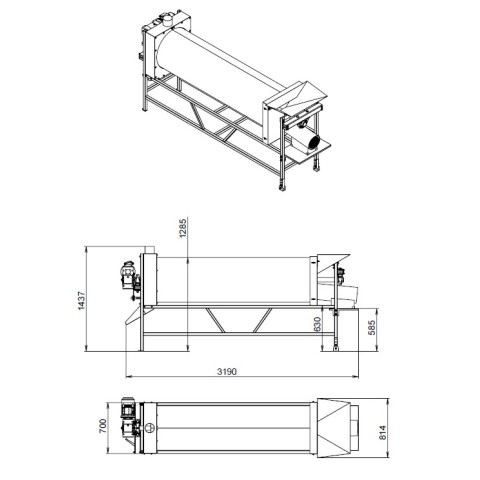

Convective drum dryer ABM

Convective rotary drum dryers are used for drying granular, loose and bulk materials. They can be used for drying salt, coffee, various granules, powders, grain, nuts, seeds, fruit/vegetable bagasse, and many other products. When used in other industries, the dryer allows for the drying of salt, sand, expanded clay granules, and other similar non-flammable substances. For more information, send us a request.

The drum dryer can be configured to operate with either electric heating or gas heating (which can offer a lot more power), depending on your specific requirements and preferences.

Warning: It is not recommended to use the gas heating option for drying substances that are highly flammable, as doing so could pose a significant fire risk.

Convective rotary drum dryer for grain and spices

The product is introduced into the drying machine through a small hopper, where hot air is injected directly into the drum. The drying machine operates on a simple yet highly efficient principle. As the drum rotates, the product begins to swell inside it. The combined action of the airflow and the drum's rotation gradually dries the material. This dryer, utilizing a convective drying method, is specifically designed for drying bulk materials through the simultaneous effects of hot airflow and the drum's rotational movement.

Dryers are designed to dry bulk materials, they can be used for continuous operation.

When ordering a dryer, you can choose the heat source ŌĆö it can be equipped with either an electric hot-air heater or a gas (LPG) heater. When selecting a heat source, it is important to note that the gas-heated version is not suitable for drying flammable or combustible products, as well as completely dry substances. In such cases, the materials being dried must have sufficient moisture content to prevent combustion. Additionally, the equipment and operating area for the dryer must be equipped with a fire extinguishing system.

Main components of the rotary drum dryer:

- Rotary drum with paddles for drying,

- Robust stainless steel frame,

- Lifting mechanism to adjust the drum angle,

- Stainless steel hopper for product loading.

Additional options:

- Protective covers for enhanced operator safety during operation,

- Frequency converter to adjust the drum rotation speed,

- Electric or gas powered hot air generator,

- Feeding conveyor for consistent dosing,

- Cyclone dust collector for airborne particles.

Drum dryers are widely used in sectors such as:

- food processing

- agriculture

- chemical

- construction

- and other industrial fields.

Products that can be dried using convective rotary dryers:

Food industry

- salt

- coffee

- grain

- seaweed

- nut bagasse

- seeds

- seed bagasse

- fruit bagasse

- vegetable bagasse

- granules and others, etc.

Chemical industry

- salts

- sand

- clay

- expanded clay granules, etc.

Not recommended for drying products that are too powdery or tend to become excessively airborne during mixing and drying.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

You might also like

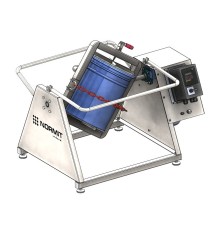

The NORMIT drum mixers are designed for thorough mixing for products such as combined feed for animals, infant formulas, baby food, food concentrates and additives, sports supplements and nutrients, coffee, tea, pharmaceuticals and chemical products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l/ 200l/ 500l

Barrel mixers are used to mix a wide range of loose and granular products in a shipping/barrel container. The available mixer models are suitable for the following volumes:

ConMix 20 - 20-30 liter standard drums with a diameter of 316 mm, adjustable frame structure height

ConMix 75 - 48-65 liter standard barrels with a diameter of 400 mm, adjustable frame structure height

- It is possible to use standard food containers ranging from 20-65 liters

- Easy control via a frequency converter as a stand-alone control panel

- Safe operation thanks to a roll bar with a position sensor

- Engine power, kW: 0,37/ 0,55/ 1,1

- Volume: 20l/ 75/ 100l

The NDM + drum mixer is designed for thorough mixing while retaining the structure of loose products without dead zones and with relatively low consumption and short mixing time. Made for mixing products such as coffee, tea, nutrients and supplements, baby food and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

Wheat washer, huller and separator is used for the preparation of grain for milling. Price depends on your production capacity.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

This mixing machine is intended for mixing┬Āsauerkraut with carrots, beets, salt, spices, also for salad, kimchi mixing etc.

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l/ 600l/

The high quality atmospheric 1500 kg condensate honey dryer is designed specifically for professional honey dehumidification.

Price depends on the chosen option.

- Material: Stainless steel

- Working volume: 1000

- Dimensions, mm: 3600x1400x2000

A tilting frying pan with a stirrer and indirect electric heating using thermal oil is designed for processing small batches of raw materials, making it suitable for stewing and frying various foods. The automatic stirring feature enhances the preparation of vegetables, fish, meat, and sauces.

- Compact model

- Uniform heating due to the thermal oil

- Simple controls

- Electric tilt of the working bowl

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 140l

- Total power, kW: 19

A vacuum honey dryer is used to dehydrate (remove moisture from) honey at sub-atmospheric pressure.

- This highly efficient and innovative vacuum drying process guarantees honey drying rates exceeding 1% per hour!

- The vacuum dryer allows for quick and gentle drying of honey at temperatures up to 39┬░C without increasing hydroxymethylfurfural (HMF) levels.

- Any heat source (hot water, steam) can be used to supply thermal energy to the dryer's jacket.

- The specially designed mixing device enhances heat transfer within the product, improving its thermal efficiency and significantly reducing drying energy costs.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar

Smoking and cooking chambers are designed for thermal processing of meat, sausages, poultry, fish and cheese. You can smoke, steam, dry, bake and cool products up to 120 degrees in our chambers. Smoking chambers are made in four types of supply: oil, gas, electricity and steam.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Voltage: 230 V/ 380-400V

Designed for "cold" vacuum drying of products sensitive to high temperatures, also suitable for liquid and viscous products.

The simple dryer provides a reliable and cost-effective solution for food producers looking for precise control over the drying process.

- Material: Stainless steel

- Principle of operation: Batch mode

We offer different types of honey dryers with a capacity for this model ranging from 50 kg up to 1000 kg.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

The vacuum batch dryer is suitable for gentle and high-quality dehydration to obtain a product with low solvent/moisture content.

- Special stirrer for uniform heat distribution and mixing

- Drying of heat-sensitive wet solids

- Suitable for the separation of suspensions and drying extracts

- Low processing temperature due to a deep vacuum

- Material: Stainless steel

- Volume: 300l/ 600l/

Working volume: 1000 l =┬ĀHoney dose: 1500 kg

Working volume: 2000 l =┬ĀHoney dose: 3000 kg

The price depends on the chosen option.┬Ā

- Productivity: do 3000 kg

- Material: Stainless steel

- Country of origin: Slovakia

- Working volume: 2000 l

- Geometric volume: 4000 l

- Dimensions, mm: 4300x2760x2450

A drying chamber for vegetables and fruits is a specialized enclosure designed to gently remove moisture from produce, preserving its natural flavors and nutrients while extending its shelf life.

- Type of the equipment: Individual machine

- Weight: 215

- Area, m┬▓: 14

- Number of shelves: 40

The high quality atmospheric condensate honey dryer is designed specifically for professional honey dehumidification.

The price depends on the options you choose.┬Ā

- Material: Stainless steel

- Working volume: 2000 l

- Dimensions, mm: 5200x1590x1680

A vacuum deaerator is extensively used in the food industry to remove gases from products that may retain some bubbles post-processing. Additionally, a flow deaerator is utilized to minimize foaming in products, ensuring a denser structure, especially prior to packaging. Vacuum deaerators play a crucial role in eliminating specific odors from the products, such as in the production of juices, purees, and herbal drinks. This process significantly contributes to enhancing the overall quality and taste of the final product.

- Enhances product quality, structure, and shape

- Prevents oxidation by removing gases

- Preserves organoleptic properties and extends the shelf life

- Suitable for thick and viscous products

- The flow principle allows for the installation of this equipment in existing production lines

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 255 kg

- Volume: 500l

- Voltage: 380-400V

- Geometric volume: 170 l

- Dimensions, mm: 2350 x1500 x2000

The cylindrical drum rotary machine is designed for drying and crystallizing liquid and paste food products into solid crystals.

- Compact tabletop design

- Automatic knives for cutting the product film

- Adjustable product layer thickness when applied to the drum

- Adjustable drum rotation speed to control drying time

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This industrial hybrid drying cabinet combines two drying principles: heat pump (condensation) and convection (forced circulation of heated air). This dryer is designed for fast, efficient, energy-saving, and "cold" drying of vegetables, fruits, berries, mushrooms, legumes, herbs, meat, fish, and even liquid or semi-liquid products by replacing the shelves with standard GN 2/1 containers. The size of one shelf is 530 x 650 mm.

- Dual technology: condensation drying + hot air convection

- Energy-efficient with optimized consumption (approx. 0.9ŌĆō1.3 kWh depending on mode)

- Drying area expandable up to 14 m┬▓ (optional)

- Uniform drying thanks to forced air flow and controlled moisture removal

- Gentle operation at low temperatures for maximum preservation of nutrients and color

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l