Vacuum honey dryer 3300 VPD

The peculiarity of this unit is the combination of several functions: homogenization and drying of honey. The vertical vacuum dryer allows you to dry honey weighing up to 3300 kg in a short time while preserving its useful properties, color, taste, and organoleptic qualities. The vacuum honey dryer has a number of significant advantages over classic atmospheric honey dryers due to the reduction of processing time and the preservation of its beneficial properties, which is achieved by drying at a lower temperature.

- The drying process occurs much faster due to the evaporation of moisture under vacuum.

- High degree of homogenization of honey due to the operation of a special mixing device.

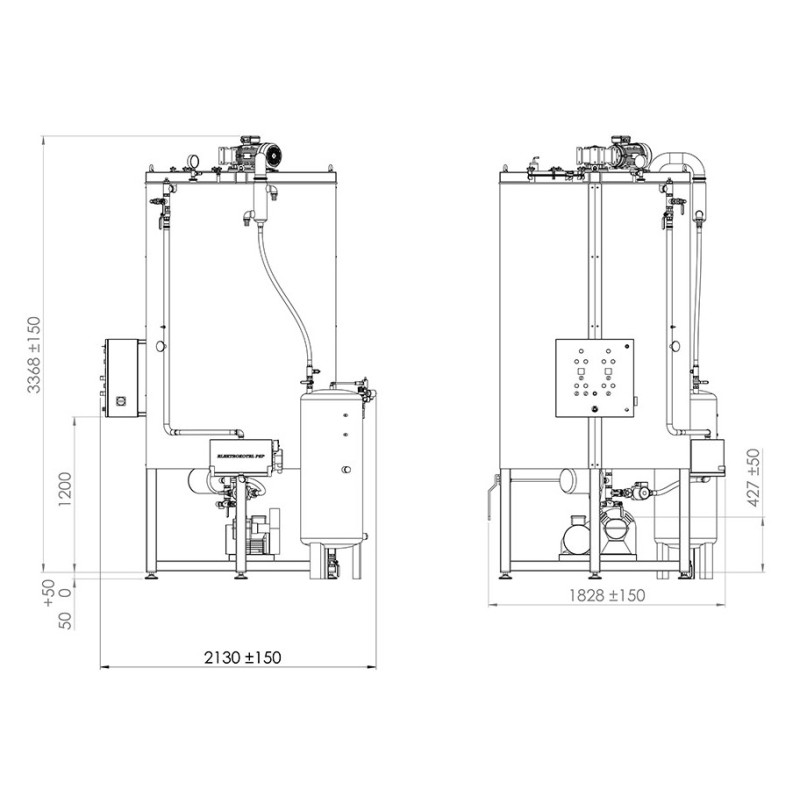

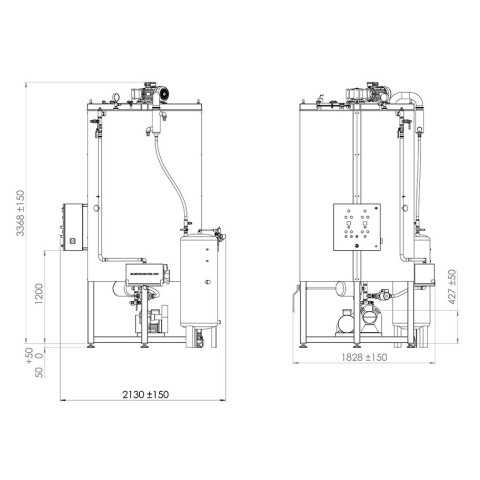

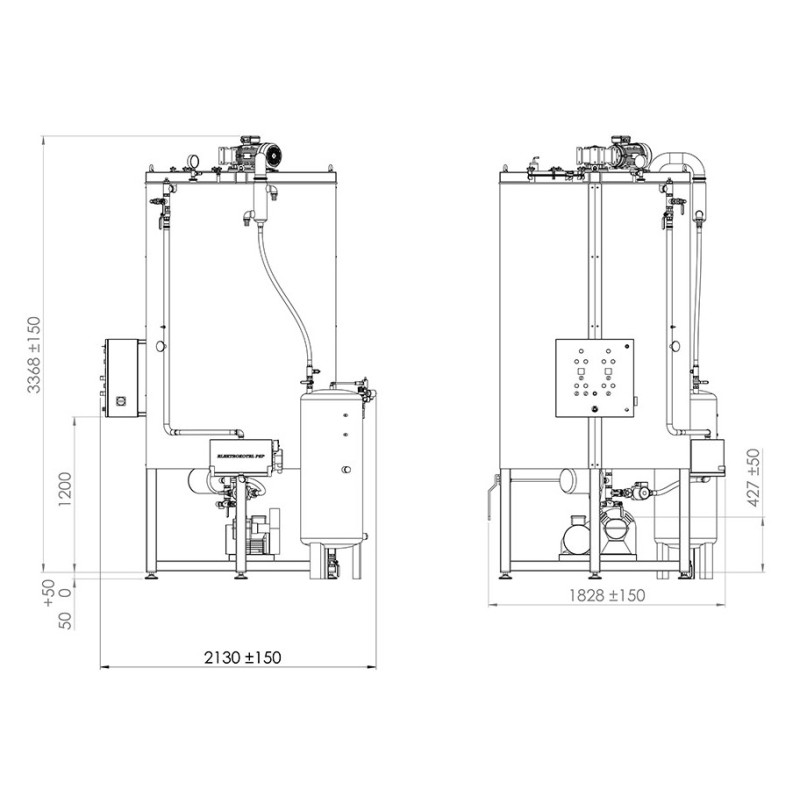

- The narrow vertical design does not require large production areas while boasting high productivity.

The vacuum honey dryer-homogenizer allows you to dry up to 3300 kg of honey in one batch under vacuum at a rate of up to 1% per hour.

Ideal for:

|

|

Advantages

- A special type of mixing device that allows drying the product in a thin layer by constantly mixing the honey and spreading it along the walls of the dryer.

- Two functions in one device: the ability to not only dry but also homogenize honey.

- The drying process is much faster due to moisture evaporation under vacuum.

- The product is dried at a low temperature due to the vacuum, thus reducing the risk of HMF (hydroxymethylfurfural) formation in honey.

- Narrow vertical design that minimizes the need for large production areas.

- Hygienic design.

- Clear and convenient control.

Basic Version

The unit's tank is equipped with a screw conveyor, a special heating "jacket," a heating system, a vacuum system, a condenser, and a control panel. The narrow vertical design requires minimal space in production facilities. The screw serves as the mixing device, homogenizing different types of honey and assisting in squeezing the honey from the container during unloading.

Operating Principle

The vacuum drying process lowers the boiling point of water, allowing it to evaporate at lower temperatures, thus ensuring that the honey does not overheat and retains its important chemical and biological properties. The system ensures effective removal and condensation of steam outside the honey, with the steam being directed to an external condenser.

Mixing Different Honeys

During this process, honey is homogenized, meaning you can blend honey from different beekeepers with varying characteristics. Once poured into the unit, the machine extracts moisture as needed while simultaneously mixing the honey, resulting in 3300 kg of homogeneous honey.

Technical Data

- Geometric volume of the vacuum tank: 2500 liters

- Drive of the mixing device: 3 kW

Technical Requirements

- Ice water station with a temperature of 5-7┬░C for proper operation of the condensate collection and drainage system.

- Compressed air for the vacuum system with a pressure of 6-10 Bar.

Options

- Display window with a backlight

- 200 l vertical pressure tank for condensate collection

- Ice water station

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

You might also like

The high quality atmospheric condensate honey dryer is designed specifically for professional honey dehumidification.

The price depends on the options you choose.┬Ā

- Material: Stainless steel

- Working volume: 2000 l

- Dimensions, mm: 5200x1590x1680

The price is indicated without a source of compressed air - compressor (optional).

This is periodic type of equipment designed for removing moisture and excess water from honey under vacuum conditions. This pilot vacuum dryer can be used for processing small volumes of honey directly at apiaries.

- Drying rate up to 1% per hour! (with a gradual decrease as the concentration increases)

- Large heat transfer area

- Low drying temperature thanks to the vacuum

- Easy operation and maintenance

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100 - 140 kg

- Total power, kW: 6,5

- Voltage: 220-230V 380-400V

- Max vacuum: -0,8 Bar

A vacuum honey dryer is used to dehydrate (remove moisture from) honey at sub-atmospheric pressure.

- This highly efficient and innovative vacuum drying process guarantees honey drying rates exceeding 1% per hour!

- The vacuum dryer allows for quick and gentle drying of honey at temperatures up to 39┬░C without increasing hydroxymethylfurfural (HMF) levels.

- Any heat source (hot water, steam) can be used to supply thermal energy to the dryer's jacket.

- The specially designed mixing device enhances heat transfer within the product, improving its thermal efficiency and significantly reducing drying energy costs.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar

We offer different types of honey dryers with a capacity for this model ranging from 50 kg up to 1000 kg.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

The high quality atmospheric 1500 kg condensate honey dryer is designed specifically for professional honey dehumidification.

Price depends on the chosen option.

- Material: Stainless steel

- Working volume: 1000

- Dimensions, mm: 3600x1400x2000

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 255 kg

- Volume: 500l

- Voltage: 380-400V

- Geometric volume: 170 l

- Dimensions, mm: 2350 x1500 x2000

Convective rotary drum dryers are used for drying granular, loose and bulk materials. They can be used for drying salt, coffee, various granules, powders, grain, nuts, seeds, fruit/vegetable bagasse, and many other products. When used in other industries, the dryer allows for the drying of salt, sand, expanded clay granules, and other similar non-flammable substances. For more information, send us a request.

The drum dryer can be configured to operate with either electric heating or gas heating (which can offer a lot more power), depending on your specific requirements and preferences.

Warning: It is not recommended to use the gas heating option for drying substances that are highly flammable, as doing so could pose a significant fire risk.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Fast, sleek, quiet, user-friendly, safe, smooth-running commercial salad dryer, designed to efficiently dry up to 6 Kg.

- Engine power, kW: 0,55

- Principle of operation: Batch mode

Working volume: 1000 l =┬ĀHoney dose: 1500 kg

Working volume: 2000 l =┬ĀHoney dose: 3000 kg

The price depends on the chosen option.┬Ā

- Productivity: do 3000 kg

- Material: Stainless steel

- Country of origin: Slovakia

- Working volume: 2000 l

- Geometric volume: 4000 l

- Dimensions, mm: 4300x2760x2450

The simple dryer provides a reliable and cost-effective solution for food producers looking for precise control over the drying process.

- Material: Stainless steel

- Principle of operation: Batch mode

We offer different capacity multi belt dryers and roasting ovens.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This industrial hybrid drying cabinet combines two drying principles: heat pump (condensation) and convection (forced circulation of heated air). This dryer is designed for fast, efficient, energy-saving, and "cold" drying of vegetables, fruits, berries, mushrooms, legumes, herbs, meat, fish, and even liquid or semi-liquid products by replacing the shelves with standard GN 2/1 containers. The size of one shelf is 530 x 650 mm.

- Dual technology: condensation drying + hot air convection

- Energy-efficient with optimized consumption (approx. 0.9ŌĆō1.3 kWh depending on mode)

- Drying area expandable up to 14 m┬▓ (optional)

- Uniform drying thanks to forced air flow and controlled moisture removal

- Gentle operation at low temperatures for maximum preservation of nutrients and color

The unique feature of this vacuum honey evaporator model, distinguishing it from a honey dryer, is its ability to create a deep vacuum with a residual pressure of up to 0.08 Bar during processing, and thus lowering the processing temperature! This innovative unit not only allows for quick and efficient drying of honey but also enables the immediate evaporation of water, producing a semi-finished product suitable for the subsequent production of «dry honey» or powdered honey.

- There is no need to have a large drying surface ŌĆō an evaporation mirror.

- There is no need to install a mixing device for thick and viscous products.

- Low evaporation temperature of moisture ŌĆō water from honey, at which its quality and medicinal properties are not compromised, and the risk of HMF growth is reduced to almost zero.

- Fast and efficient dehydration of honey at a low processing temperature.

- Material: Stainless steel

- Principle of operation: Batch mode

- Max vacuum: -1 Bar

Deaerator is used for the removal of air bubbles from the puree. Price depends on the required volume and production capacity.

For more information, send us a request.┬Ā

- Productivity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m┬▓: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

This convective honey dryer is used for drying and mixing honey, it is a high-performance solution for thoroughly mixing honey while simultaneously removing excess moisture.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 230 V/ 380-400V

We offer different capacity infrared dryers.

- Productivity: 250 kg/h/ 1000 kg/h/ 1500 kg/h/ 2000 kg/h / 3000 kg/h / 6000 kg/h

We offer professional infrared dryers from 8 to 56 trays with a capacity of 200 to 3000 kg/day for vegetables, fruits, tea, herbs, mushrooms, medicinal herbs and other products. The dryers of this type is a turnkey solution based on two technologies - direct infrared and air convection drying.

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Smoking and cooking chambers are designed for thermal processing of meat, sausages, poultry, fish and cheese. You can smoke, steam, dry, bake and cool products up to 120 degrees in our chambers. Smoking chambers are made in four types of supply: oil, gas, electricity and steam.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Voltage: 230 V/ 380-400V